Method for preparing nanometer antibacterial core-shell polymer microsphere through emulsion polymerization

An emulsion polymerization, polymer technology, applied in the fields of botanical equipment and methods, preparation of microspheres, chemicals for biological control, etc., can solve problems such as affecting stability and affecting antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

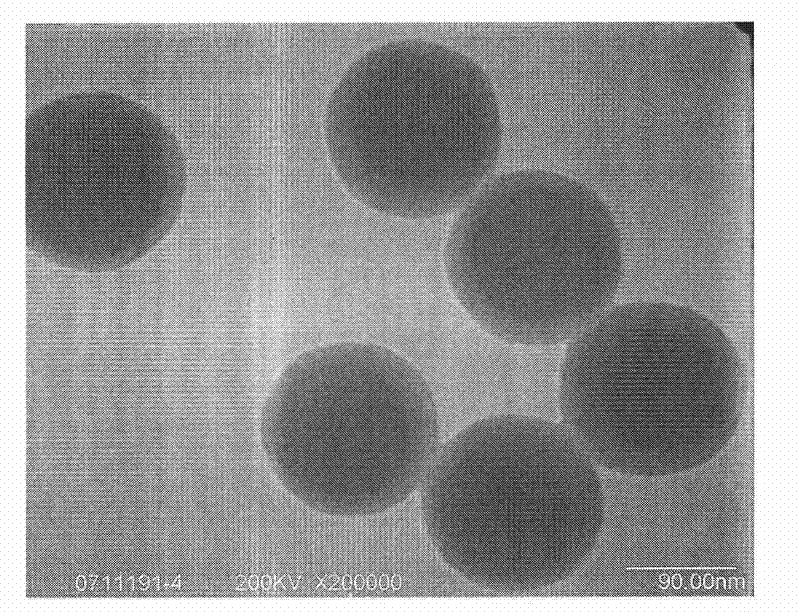

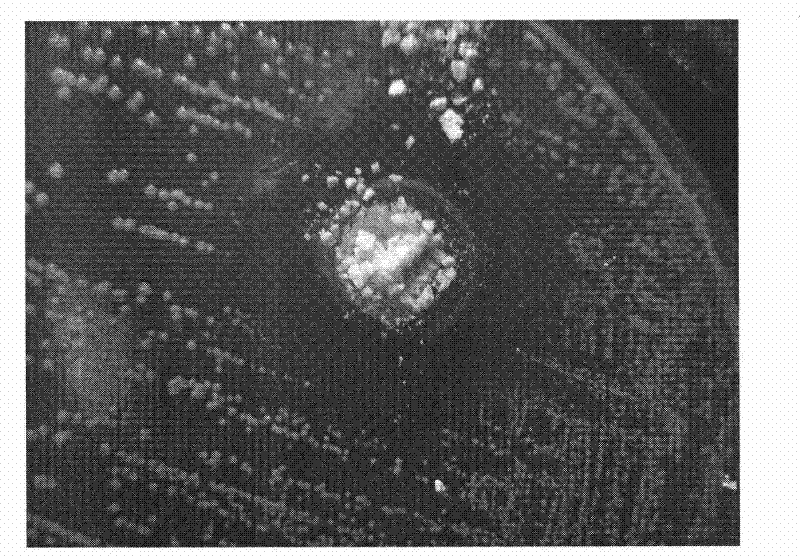

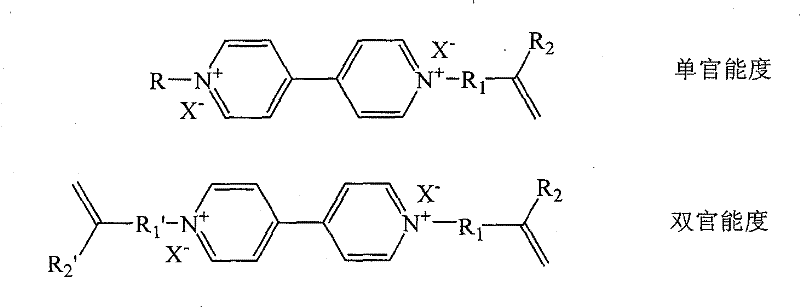

[0069] In the reactor equipped with stirring device, nitrogen device, condensing device and feeding port, add 1.25ml (0.05, with the volume ratio of reaction medium, the following examples are the same) styrene (St), 0.05g (0.044, with The mass ratio of the main monomer, the following examples are the same as) N-hexyl-N'-(4-vinylbenzyl)-4,4'-bipyridine bisalt bromide chloride (HVV) and 23ml water, nitrogen removal Oxygen, stirring to form a uniform mixed solution; 0.02g (0.018, with the mass ratio of the main monomer, the same as in the following examples) 2,2'-azobisisobutylsulfinium hydrochloride (AIBA) was dissolved in 2ml water, After the temperature of the reactor rose to 70°C, AIBA aqueous solution was added to initiate the St polymerization reaction for 10 hours to obtain a stable latex; the obtained latex was centrifuged at 15000r / min for 30 minutes, washed repeatedly with water and methanol, and then dried at room temperature to obtain a powder polymer microspheres. ...

Embodiment 2

[0071] Same as specific implementation

[0072] Embodiment 1, only the added monomer is 1.25ml (0.05) styrene (St), 0.05ml (0.04, the volume ratio with the main monomer, the following examples are the same) acrylic acid. SEM observation and analysis microsphere particle size is 108nm, coefficient of variation is 4.5%, TEM observation analysis shell thickness is 17nm, antibacterial test observed the formation of obvious bacteriostatic zone.

Embodiment 3

[0074] Same as specific implementation

[0075] Example 1, except that the added monomers are 1.25ml (0.05) styrene (St), 0.02ml (0.016) N-isopropylacrylamide. SEM observation and analysis microsphere particle size is 116nm, coefficient of variation is 5.1%, TEM observation analysis shell thickness is 23nm, antibacterial test observed the formation of obvious bacteriostatic zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com