Method for preparing high dispersion supported hydrogenation catalyst

A catalyst and hydrogenation reaction technology, which is applied in the field of preparation of highly dispersed and loaded hydrogenation catalysts, can solve the problems of complex preparation process, high price, and low nanoparticle content, and achieve high catalytic activity, short preparation cycle and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] These examples illustrate the preparation of a NiB catalyst supported by a solid content of 20% aluminum sol.

[0023] Prepare a nickel acetate solution with a concentration of 0.1mol / L, mix it with a certain amount of aluminum sol with a solid content of 20%, and then prepare KBH with a concentration of 1.2mol / L 4 solution (B:Ni=3.0:1.0, atomic ratio), at 20°C, under the protection of Ar gas, the KBH 4 Drop it into the mixed solution of aluminum sol and nickel salt with a solid content of 20% at a speed of 1-6ml / min until no gas is generated during the reaction. Nickel accounts for 15% by weight of the catalyst, and the prepared catalyst is used directly, or the catalyst is washed until the washing liquid is neutral, and then stored in water or ethanol. The resulting catalyst is designated as A1.

[0024] The catalyst obtained in this example is used to prepare 4-aminophenol by hydrogenating 4-nitrophenol in the liquid phase, that is: in a 100ml autoclave, add a cata...

Embodiment 2

[0026] These examples illustrate the preparation of NiB catalysts with different loadings.

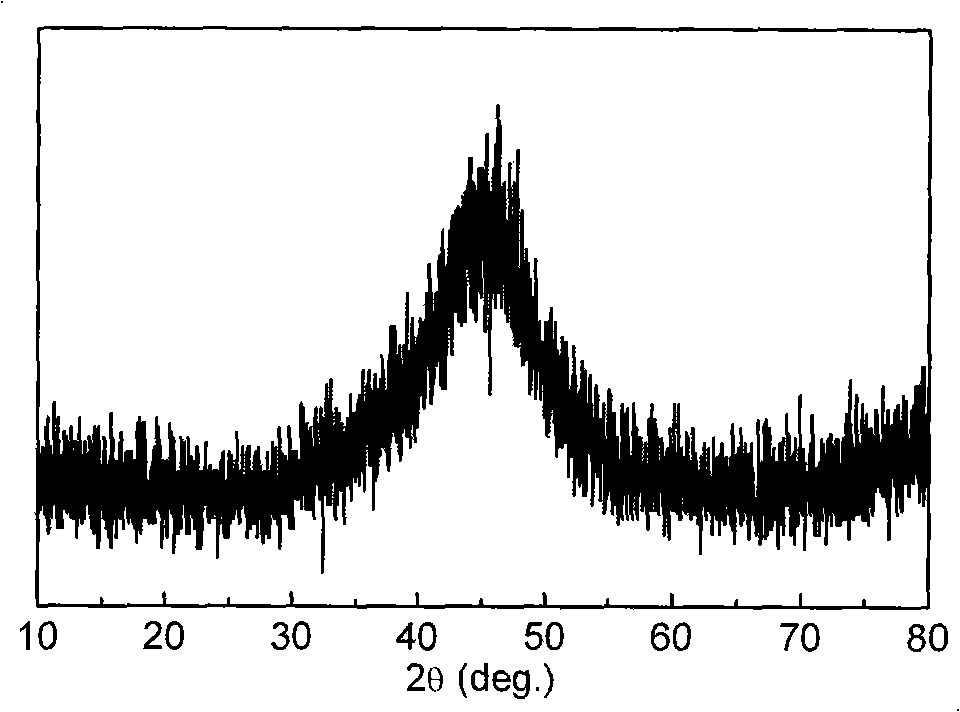

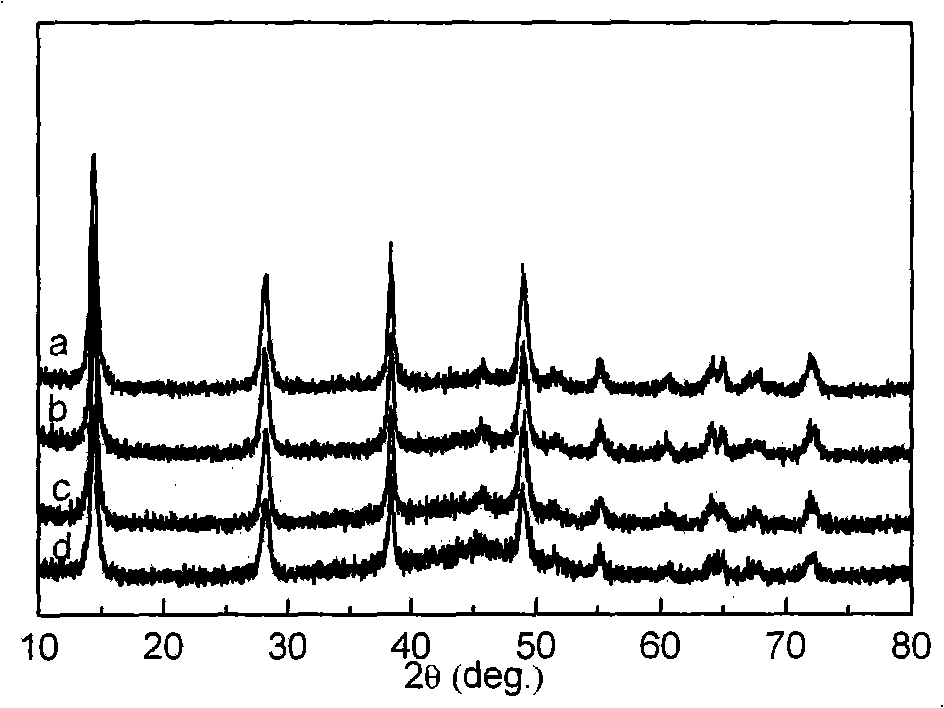

[0027]Prepare a nickel acetate solution with a concentration of 0.1mol / L, mix it with a certain amount of aluminum sol with a solid content of 20%, and then prepare KBH with a concentration of 1.2mol / L 4 solution (B:Ni=3.0:1.0, atomic ratio), at 20°C, under the protection of Ar gas, the KBH 4 Drop it into the mixed solution of aluminum sol and nickel salt with a solid content of 20% at a speed of 1-6ml / min until no gas is generated during the reaction. In the case of keeping the amount of nickel acetate constant, by changing the amount of aluminum sol, NiB catalysts with nickel loadings of 10wt%, 20wt%, 30wt% and 40wt% were prepared, and the prepared catalysts were used directly. Or wash the catalyst until the washing solution is neutral, and then store it in water or ethanol. Recorded as A2, A3, A4, A5 respectively, samples A2, A3, A4, A5 have figure 1 Characteristics.

Embodiment 3

[0029] These examples illustrate the procedure for supported NiB catalysts prepared at different temperatures.

[0030] Prepare a nickel acetate solution with a concentration of 0.1mol / L, mix it with a certain amount of aluminum sol with a solid content of 20%, and then prepare KBH with a concentration of 1.2mol / L 4 solution (B:Ni=3.0:1.0, atomic ratio), at 15°C, 25°C and 30°C, respectively, under the protection of Ar gas, the KBH 4 Drop it into the mixed solution of aluminum sol and nickel salt at a rate of 1-6ml / min until no gas is generated during the reaction. The prepared catalyst is directly used, or the catalyst is washed until the washing liquid is neutral, and then stored in water or ethanol, and the nickel accounts for 15% of the weight of the catalyst. Catalysts A6, A7 and A8 were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com