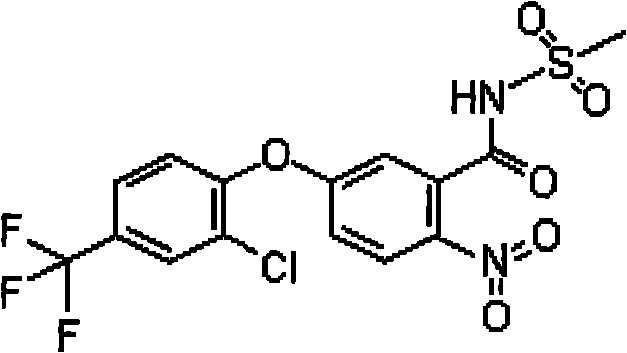

Fomesafen microemulsion and preparation method thereof

A technology of fomesafen and microemulsion, which is applied in the field of fomesafen microemulsion and its preparation, can solve the problems of pesticide residues, etc., and achieve the effects of low environmental pollution, high utilization rate of raw materials, and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] 5% fomesafen microemulsion. Get 5.3kg of 95% fomesafen technical substance, put it in 5kg of methanol solvent co-solvent, drop into 8kg of phenethylphenol polyoxyethylene polyoxypropylene ether after dissolving, 6kg of alkylbenzene sulfonate, 12kg of dehydration Sorbitan fatty acid ester surfactant, 0.5kg synergistic ether, 0.5kg phenyl glycidyl ether, after fully stirring, then solvent is dropped into the homogeneous that 58.7kg dispersion medium water and 4kg ethylene glycol antifreeze are housed Vigorously mixed and homogenized in an evaporator to obtain a clear and transparent 5% fomesafen microemulsion.

example 2

[0025] 10% fomesafen microemulsion. Get 10.6kg of 95% fomesafen former medicine, place in 8kg of cyclohexanone solvent co-solvent, drop into 7kg of alkylphenol polyoxyethylene ether after dissolving, 5kg of alkylbenzene sulfonate, 13kg of ethylene oxide Alkylnonylphenol condensate surfactant, 0.5kg butanobuterol, 0.5kg sodium sorbate, after fully stirring, put the solvent into a homogenizer containing 51.4kg of dispersion medium water and 4kg of propylene glycol antifreeze Mix vigorously and homogenize to obtain a clear and transparent 10% fomesafen microemulsion.

example 3

[0027] 15% fomesafen microemulsion. Get 95% fomesafen former medicine 15.8kg, place in the acetone solvent cosolvent of 10kg, drop into 6kg fatty alcohol ethylene oxide adduct sulfonate after dissolving, 7kg alkylnaphthalene sulfonate, 12kg ring Oxyethane nonylphenol condensate surfactant, 0.5kg castor oil, 0.5kg sodium sorbate, after fully stirring, put the solvent into the homogenizer that 44.2kg dispersion medium water and 4kg propylene glycol antifreeze are housed Intensely mixed and homogenized to obtain a clear and transparent 15% fomesafen microemulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com