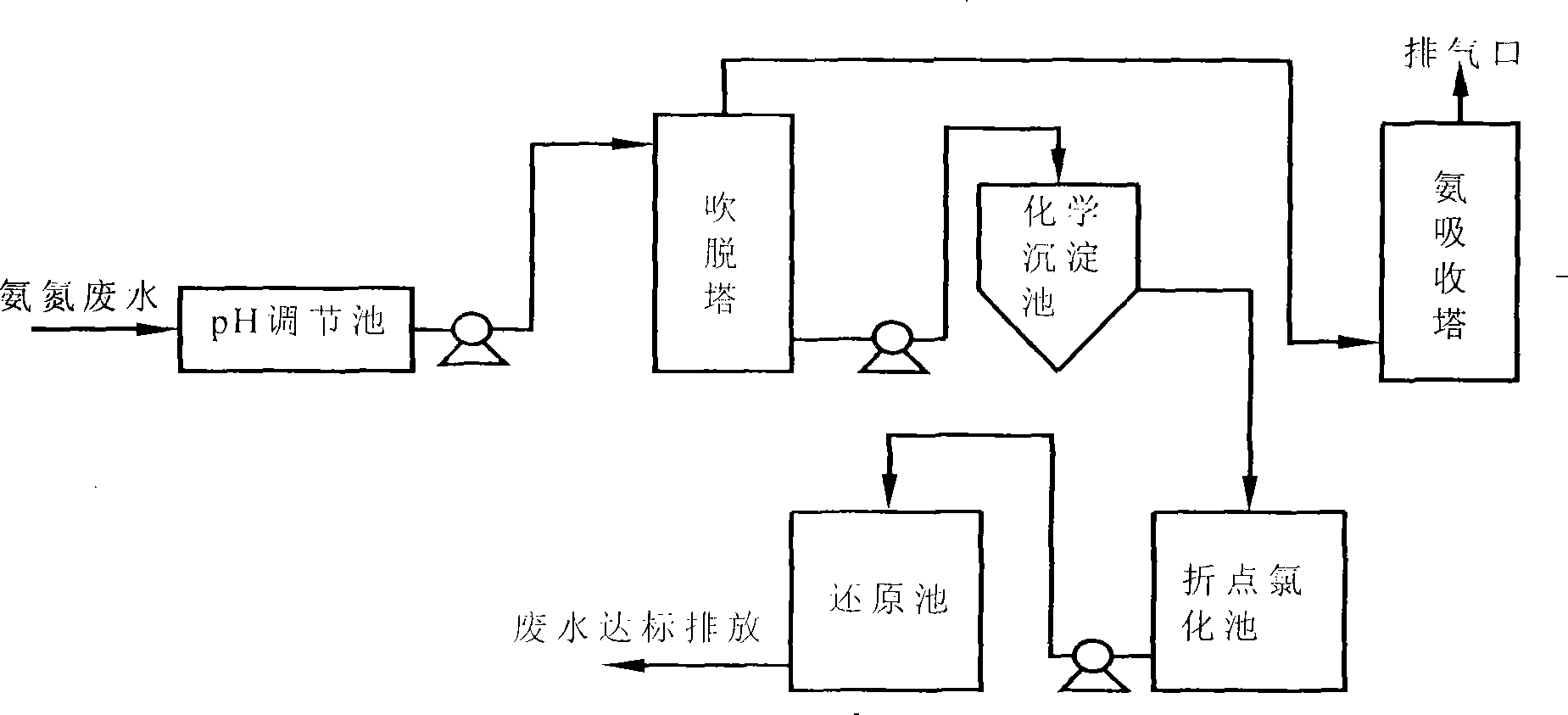

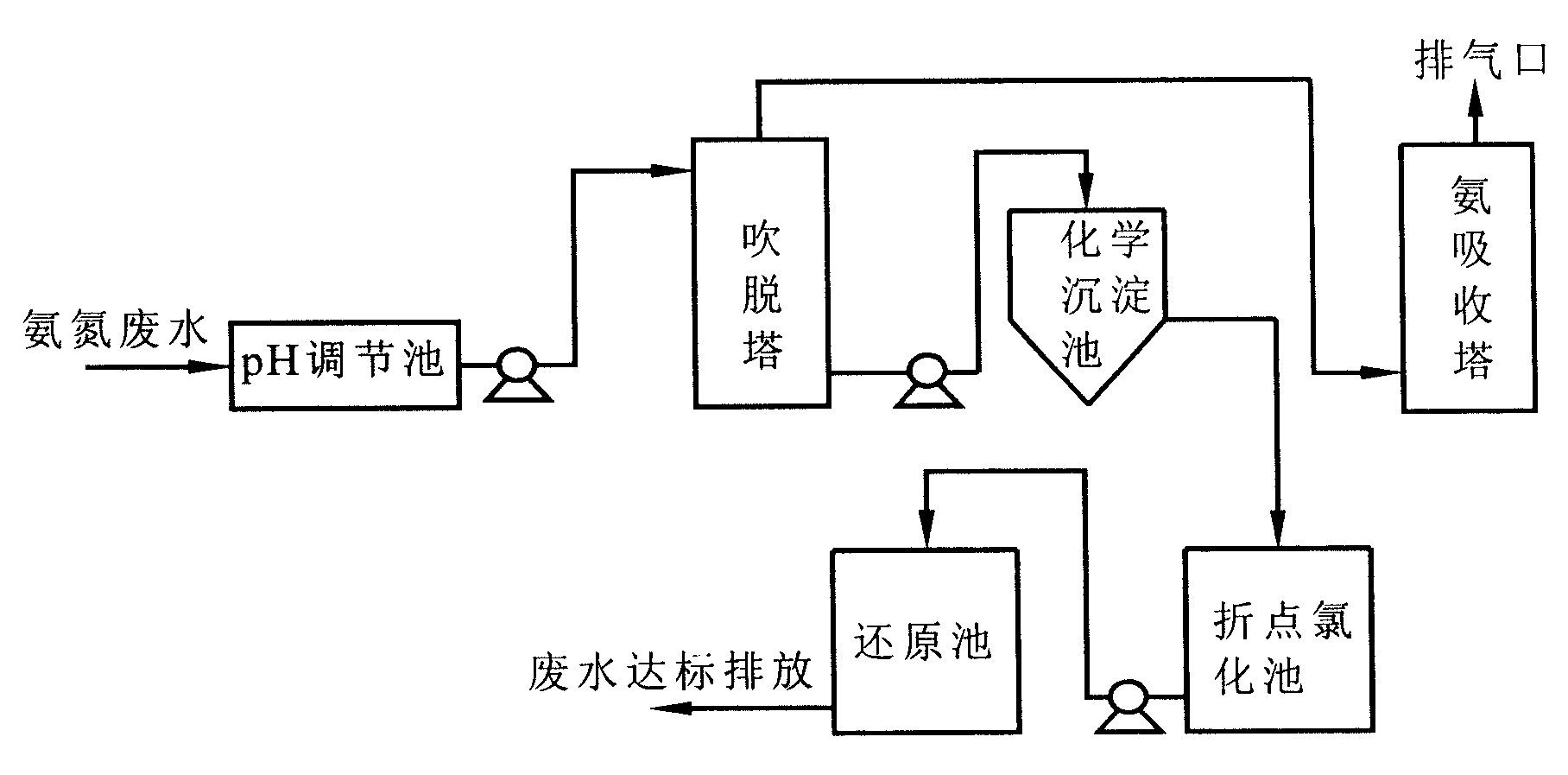

Method for treating highly concentrated ammonian wastewater with poor biodegradability by using a multiple-technique combination

A technology of ammonia nitrogen wastewater and treatment method, which is applied in the field of high concentration ammonia nitrogen wastewater treatment, can solve the problems of difficulty in ensuring wastewater discharge standards, large investment in wastewater treatment projects, and difficulty in producing wastewater, and achieves short wastewater treatment cycle and equipment utilization rate High, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First inject 1m into the pH adjustment pool 3 The concentration of ammonia nitrogen is 3900mg / L, COD is 189mg / L, and waste water with BOD / COD=0.1, add 9kg calcium hydroxide and 1.8kg sodium hydroxide according to the mass ratio of 5:1, adjust the pH=11.8, and then pump the waste water Lift to stripping tower (ratio of height to diameter of stripping tower is 7: 1, internal packing is Pall ring), carry out stripping at gas-liquid ratio of 3500, the waste gas blown out is absorbed by ammonia absorption tower, and the concentration of effluent ammonia nitrogen is 900mg / L.

[0023] The effluent then enters the chemical precipitation tank, adding magnesium sulfate and sodium dihydrogen phosphate according to the molar ratio of Mg:N:P of 1.5:1:1, adjusting the pH value to 9, stirring for 30 minutes, and then standing for 50 minutes, the resulting ammonium phosphate Magnesium precipitation is discharged from the precipitation outlet at the bottom of the chemical precipitation...

Embodiment 2

[0026] First inject 1m into the pH adjustment pool 3 The concentration of ammonia nitrogen is 4100mg / L, the COD is 489mg / L, and the waste water with BOD / COD=0.32, respectively add 9.5kg calcium hydroxide and 1.9kg sodium hydroxide according to the mass ratio of 5:1, adjust the pH=12, and then pass the pump Lift the waste water to the stripping tower (the height-to-diameter ratio of the stripping tower is 7:1, and the inner filler is a Pall ring), and strip it at a gas-liquid ratio of 3500. The waste gas blown out is absorbed by the ammonia absorption tower, and the ammonia nitrogen in the effluent is The concentration is 920mg / L.

[0027] Then enter the chemical sedimentation tank, add magnesium chloride and disodium hydrogen phosphate according to the molar ratio of Mg:N:P 1.6:1:1, adjust the pH value to 9, stir and react for 30 minutes, and then let it stand for 50 minutes, the resulting ammonium phosphate Magnesium precipitation is discharged from the precipitation outlet ...

Embodiment 3

[0030] First inject 1m into the pH adjustment pool 3 The concentration of ammonia nitrogen is 4100mg / L, the COD is 489mg / L, and the waste water with BOD / COD=0.32, respectively add 9.2kg calcium hydroxide and 2.3kg sodium hydroxide according to the mass ratio of 4:1, adjust the pH=12.2, and then pass the pump Lift the waste water to the stripping tower (the height-to-diameter ratio of the stripping tower is 7:1, and the inner filler is a Pall ring), and strip it at a gas-liquid ratio of 3700. The waste gas blown out is absorbed by the ammonia absorption tower, and the ammonia nitrogen in the effluent is The concentration is 850mg / L.

[0031] Then enter the chemical precipitation tank, add magnesium chloride and sodium phosphate according to the molar ratio of Mg:N:P 1.6:1:1, adjust the pH value to 9, stir the reaction for 25 minutes, and then let it stand for 60 minutes, and the generated magnesium ammonium phosphate precipitates It is discharged from the sedimentation outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com