Non-cyanide zinc-deposited solution and non-cyanide plating method of aluminum wheel boss using non-cyanide zinc-deposited solution

A technology of precipitating zinc and solution, which is applied in the fields of cyanide-free electroplating and cyanide-free zinc-precipitating solution for aluminum wheels, and achieves the effects of good binding force, stronger binding force and simple wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

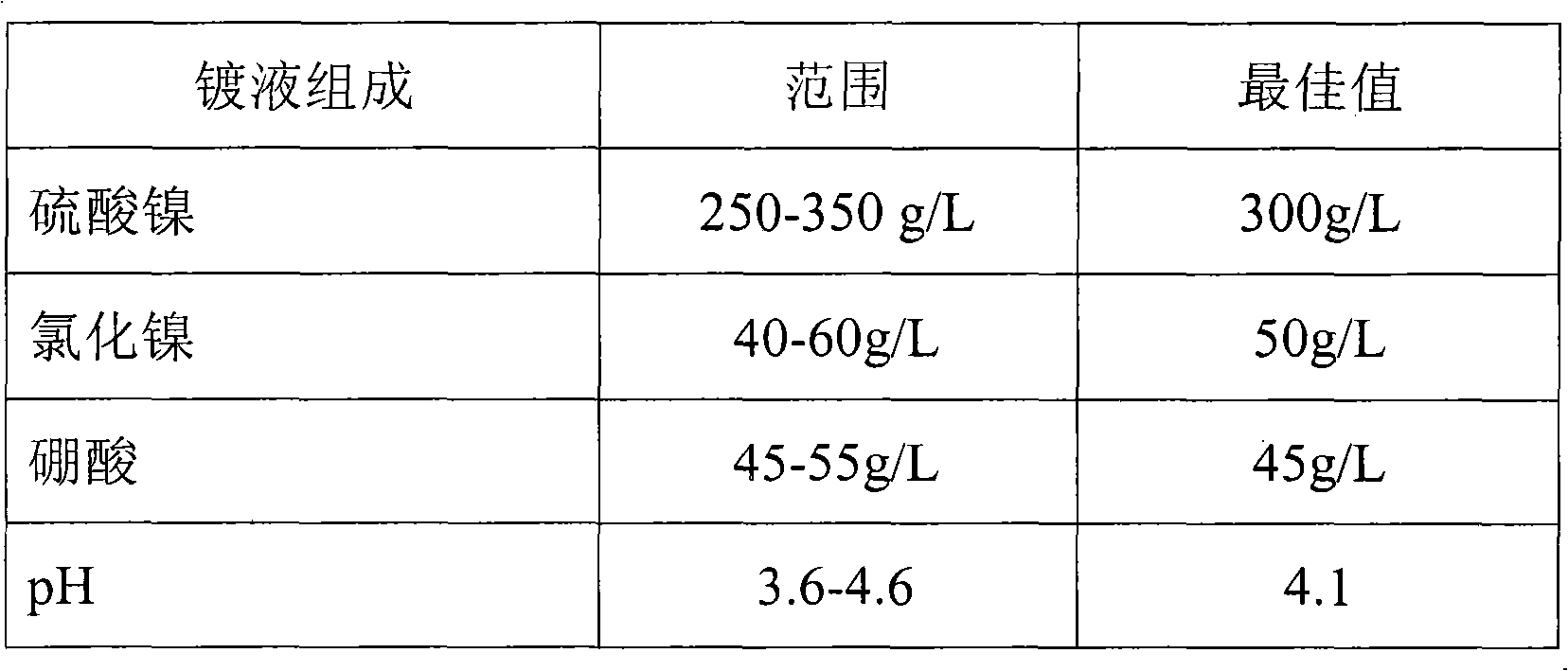

[0027] 1. Cyanide-free zinc precipitation solution is composed of the following components, the rest is water:

[0028] Composition of cyanide-free zinc precipitation solution

Proportion

Crater

350mL / L

supplements

120mL / L

8mL / L

[0029] Among them, the composition of the cylinder opener is sodium hydroxide (the content of hydroxide ion is 140g / L), copper sulfate (the content of copper ion is 2g / L), nickel chloride (the content of nickel ion is 3g / L), trichloride Iron oxide (0.8g / L iron ion content) and zinc oxide (16g / L zinc ion content); the ingredients of the supplement are sodium hydroxide and sodium gluconate at concentrations of 500g / L and 50g / L, respectively; The components of the regulator are sodium nitrate and benzotriazole, the concentrations of which are 200g / L and 20g / L respectively.

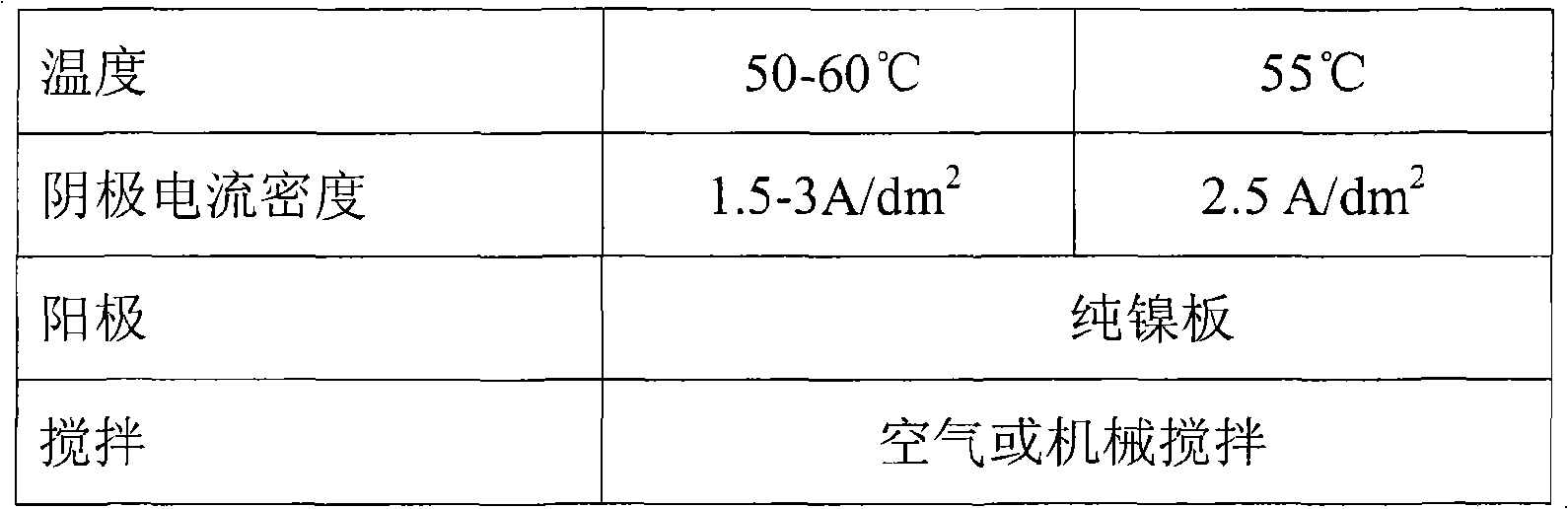

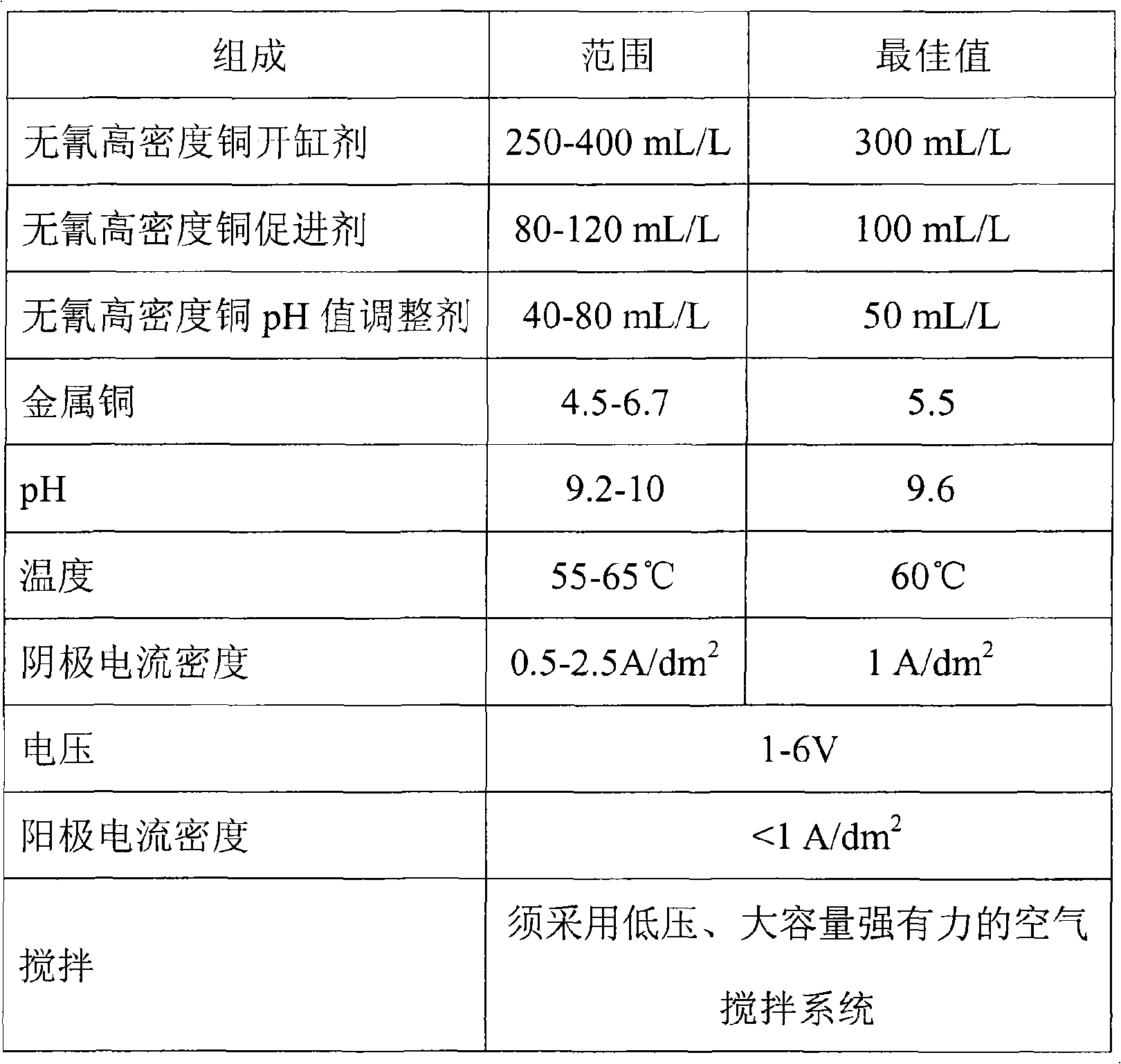

[0030] 2. The aluminum alloy wheel hub electroplating process using cyanide-free high-density copper plating solution,...

Embodiment 2

[0052] 1. Cyanide-free zinc precipitation solution is composed of the following components, the rest is water:

[0053] Composition of cyanide-free zinc precipitation solution

Proportion

Crater

350mL / L

supplements

130mL / L

10mL / L

[0054] Among them, the composition of the cylinder opener is sodium hydroxide (the content of hydroxide ion is 140g / L), copper chloride (the content of copper ion is 1.8g / L), nickel sulfate (the content of nickel ion is 3g / L), sulfuric acid Iron (0.7g / L iron ion content) and zinc oxide (16g / L zinc ion content); the ingredients of the supplement are potassium hydroxide and potassium sodium tartrate at concentrations of 520g / L and 30g / L, respectively; The ingredients of the agent are sodium nitrite and 1,3-diethylthiourea, the concentrations are 180g / L and 30g / L respectively.

[0055] 2. The aluminum alloy wheel hub electroplating process using cyanide-free high-density copper plating solu...

Embodiment 3

[0077] 1. Cyanide-free zinc precipitation solution is composed of the following components, the rest is water:

[0078] Composition of cyanide-free zinc precipitation solution

Proportion

Crater

400mL / L

supplements

120mL / L

10mL / L

[0079] Among them, the composition of the cylinder opener is potassium hydroxide (the content of hydroxide ion is 130g / L), copper chloride and copper nitrate (the content of copper ion is 1.6g / L), nickel sulfate and nickel ammonium sulfate (the content of nickel ion is 1.6g / L). 3g / L), iron sulfate and iron nitrate (0.7g / L iron ion content) and zinc oxide and zinc chloride (14g / L zinc ion content); the ingredients of the supplement are sodium hydroxide and potassium sodium tartrate , whose concentrations are 500g / L and 40g / L respectively; the components of the regulator are sodium nitrite and 2-mercaptobenzimidazole, whose concentrations are 180g / L and 30g / L respectively.

[0080] 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com