Method for growing crystal by reducing atmosphere Kyropoulos method

A technology of crystal growth and Kyropoulos method, applied in single crystal growth, crystal growth, chemical instruments and methods, etc., can solve problems such as difficulty in obtaining high-quality lithium aluminate crystals, volatilization, temperature field and temperature gradient distribution asymmetry , to achieve the effect of low energy loss, low material loss and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

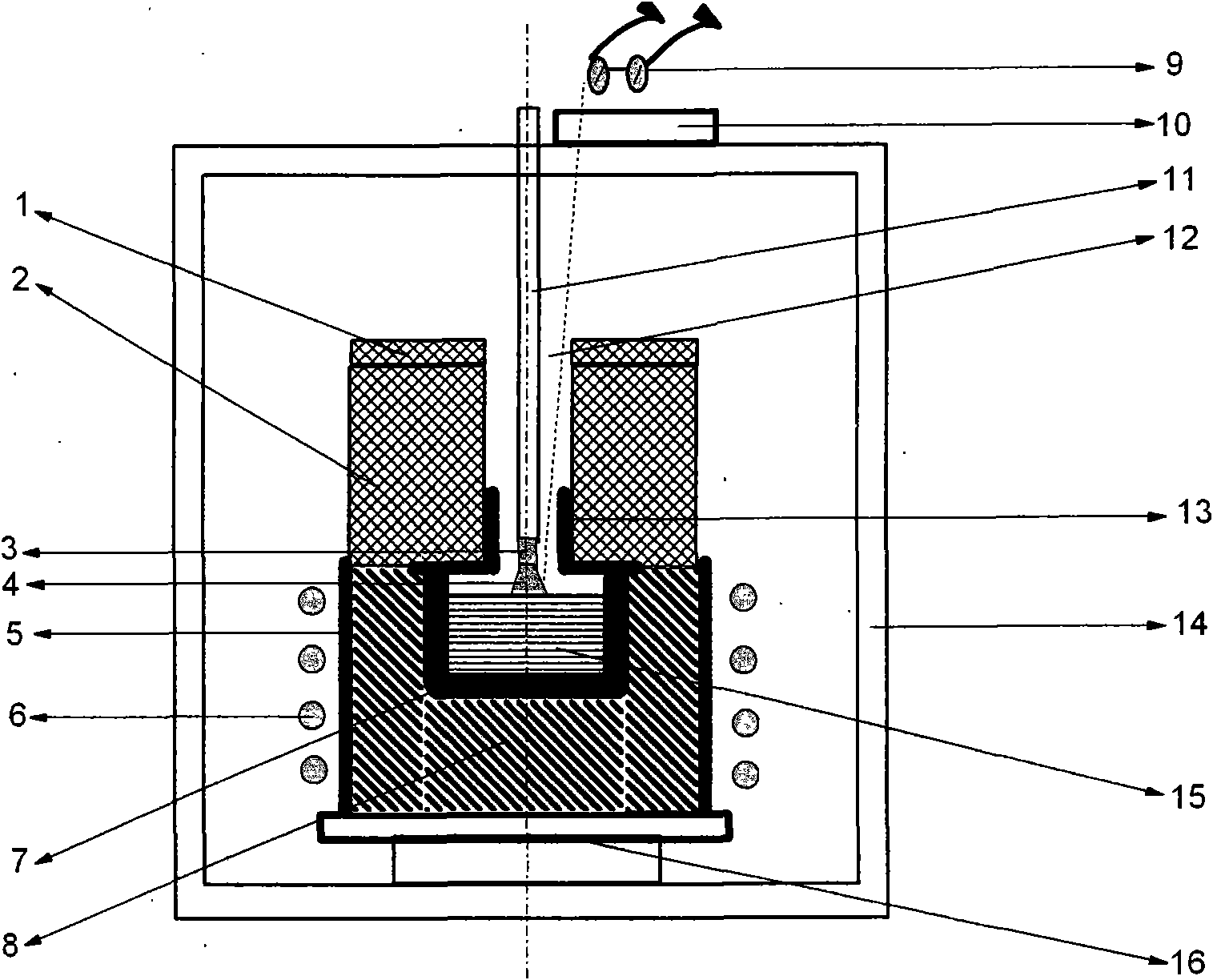

[0021] Embodiment 1: Adopt the Kyropoulos method of the present invention to grow lithium aluminate crystal

[0022] According to molar ratio Al 2 o 3 : Li 2 CO 3 =1: 1 Take by weighing the dried raw materials with a purity of 99.999%, mix them uniformly, press them into cakes under a pressure of 40MPa, and pre-sinter them at 1100°C for 10 hours; put the sintered block into the tungsten-molybdenum alloy crucible 7, and into the pull furnace, such as figure 1 As shown in the figure: 1-The upper cover of the insulation cover, 2-Hard graphite felt (or zirconia) insulation cover, 3-Seed crystal, 4-Crystal, 5-Quartz barrel, 6-Induction coil, 7-Tungsten-molybdenum alloy Crucible, 8-graphite felt, 9-human eye, 10-observation window on the upper side of the furnace wall, 11-seed crystal rod, 12-observation window on the upper cover of the heat preservation cover, 13-tungsten-molybdenum alloy afterheater, 14-furnace wall, 15-melt, 16-tray. Fill graphite felt 8 around the tungsten...

Embodiment 2

[0024] Embodiment 2: Adopt the Kyropoulos method of the present invention to grow lithium gallate crystal

[0025] According to molar ratio Ga 2 o 3 : Li 2 CO 3 =1: 1 Take by weighing the dried raw materials with a purity of 99.999%, mix them uniformly, press them into cakes under a pressure of 40MPa, and pre-sinter them at 1100°C for 10 hours; put the sintered block into the tungsten-molybdenum alloy crucible 7, and into the pull furnace, such as figure 1 As shown in the figure: 1-The upper cover of the insulation cover, 2-The hard graphite felt insulation cover, 3-Seed crystal, 4-Crystal, 5-Quartz barrel, 6-Induction coil, 7-Molybdenum crucible, 8-Graphite felt, 9-human eye, 10-observation window on the upper side of the furnace wall, 11-seed crystal rod, 12-observation window on the upper cover of the heat preservation cover, 13-tungsten-molybdenum alloy afterheater, 14-furnace wall, 15-melt, 16- tray. Fill graphite felt 8 around the molybdenum crucible 7, put a tungs...

Embodiment 3

[0026] Embodiment 3: GGG crystals grown by the Kyropoulos method of the present invention

[0027] Pack the GGG block into the tungsten crucible 7 and put it into the pulling furnace, such as figure 1 As shown in the figure: 1-Insulation cover upper cover, 2-Zirconium oxide insulation cover, 3-Seed crystal, 4-Crystal, 5-Quartz barrel, 6-Induction coil, 7-Tungsten crucible, 8-Graphite felt, 9 -human eye, 10-observation window on the upper side of the furnace wall, 11-seed crystal rod, 12-observation window on the upper cover of the heat preservation cover, 13-tungsten afterheater, 14-furnace wall, 15-melt, 16-tray. Graphite felt 8 is filled around the tungsten crucible 7, a tungsten afterheater 13 is placed above the crucible, a zirconia heat preservation cover 2 is put on the outside of the tungsten afterheater 13, and the heat preservation cover upper cover 1 is covered. Then close the furnace and evacuate (better than 0.1Pa), and then fill it with high-purity N 2 After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com