Method for preparing chloramphenicol molecularly imprinted polymeric microspheres

A technology of molecular imprinting and chloramphenicol, which is applied in the field of polymer microsphere preparation, can solve the problems of molecularly imprinted polymer particles such as irregularity and easy agglomeration, so as to avoid non-selective adsorption, increase specific surface area and clean surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

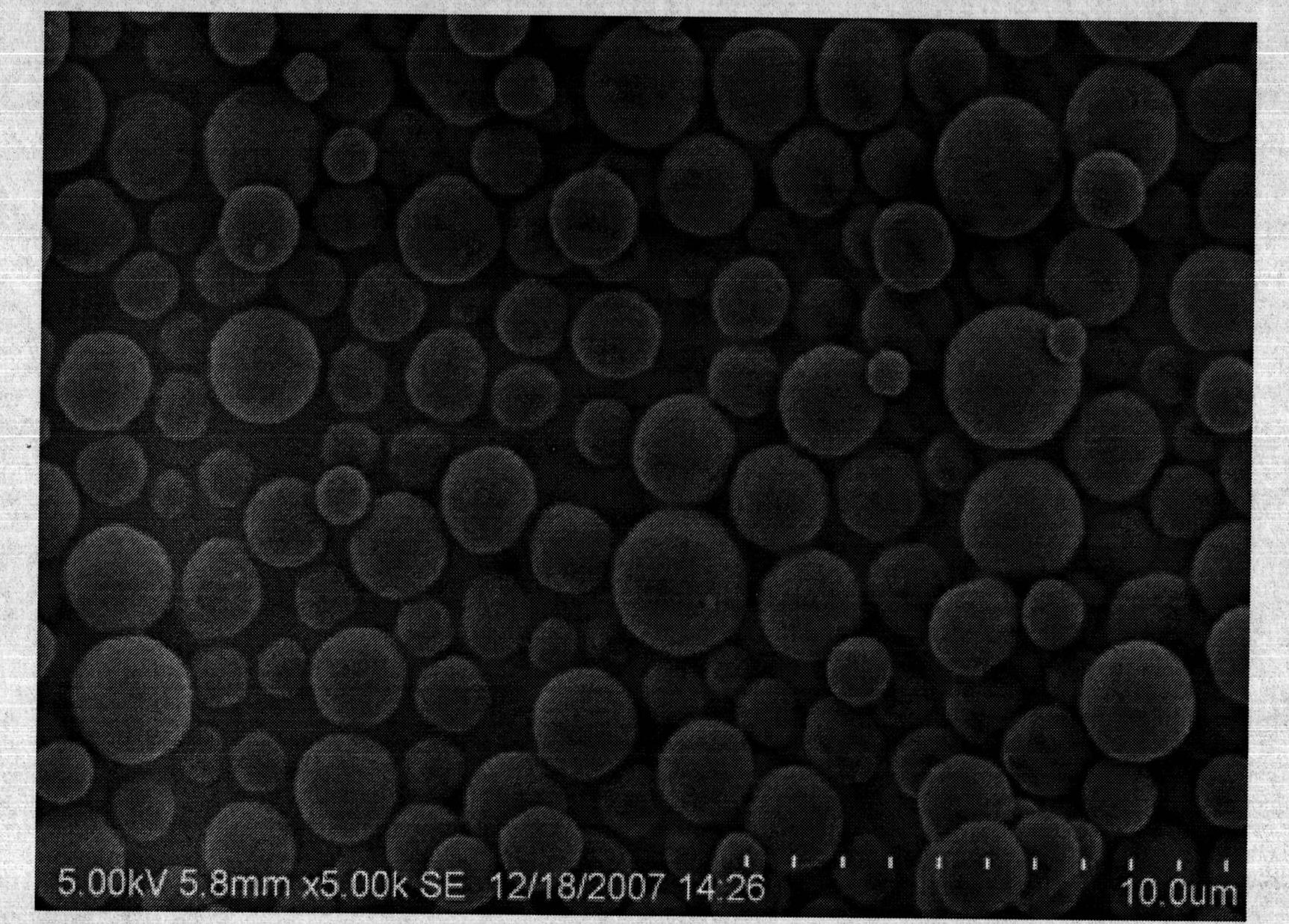

specific Embodiment approach 1

[0010] Embodiment 1: The preparation method of chloramphenicol molecularly imprinted polymer microspheres in this embodiment is as follows: 1. Dissolve methacrylic acid and chloramphenicol in acetonitrile according to the molar ratio of 2:1, wherein chloramphenicol and chloramphenicol The ratio of acetonitrile is 1mmol: 100mL, then shake for 5h under the condition of shaking frequency of 110Hz, then add ethylene glycol dimethacrylate and azobisisobutyronitrile to obtain a mixture, the mixture is shaken at an ultrasonic frequency of 40KHz, ultrasonic Ultrasonic treatment for 5 minutes at a power of 150W, then filled with nitrogen to remove oxygen and then sealed; 2. Heat the sealed mixture in a constant temperature water bath at 60°C for 24 hours, then cool, centrifuge, discard the supernatant to obtain the precipitate, and then The precipitate is naturally dried; 3, the precipitate obtained in step 2 is washed with 10% acetic acid methanol solution to remove chloramphenicol unt...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 3, the precipitate obtained in step 2 is washed with acetic acid methanol solution in a Soxhlet extractor. Others are the same as the first embodiment.

specific Embodiment approach 3

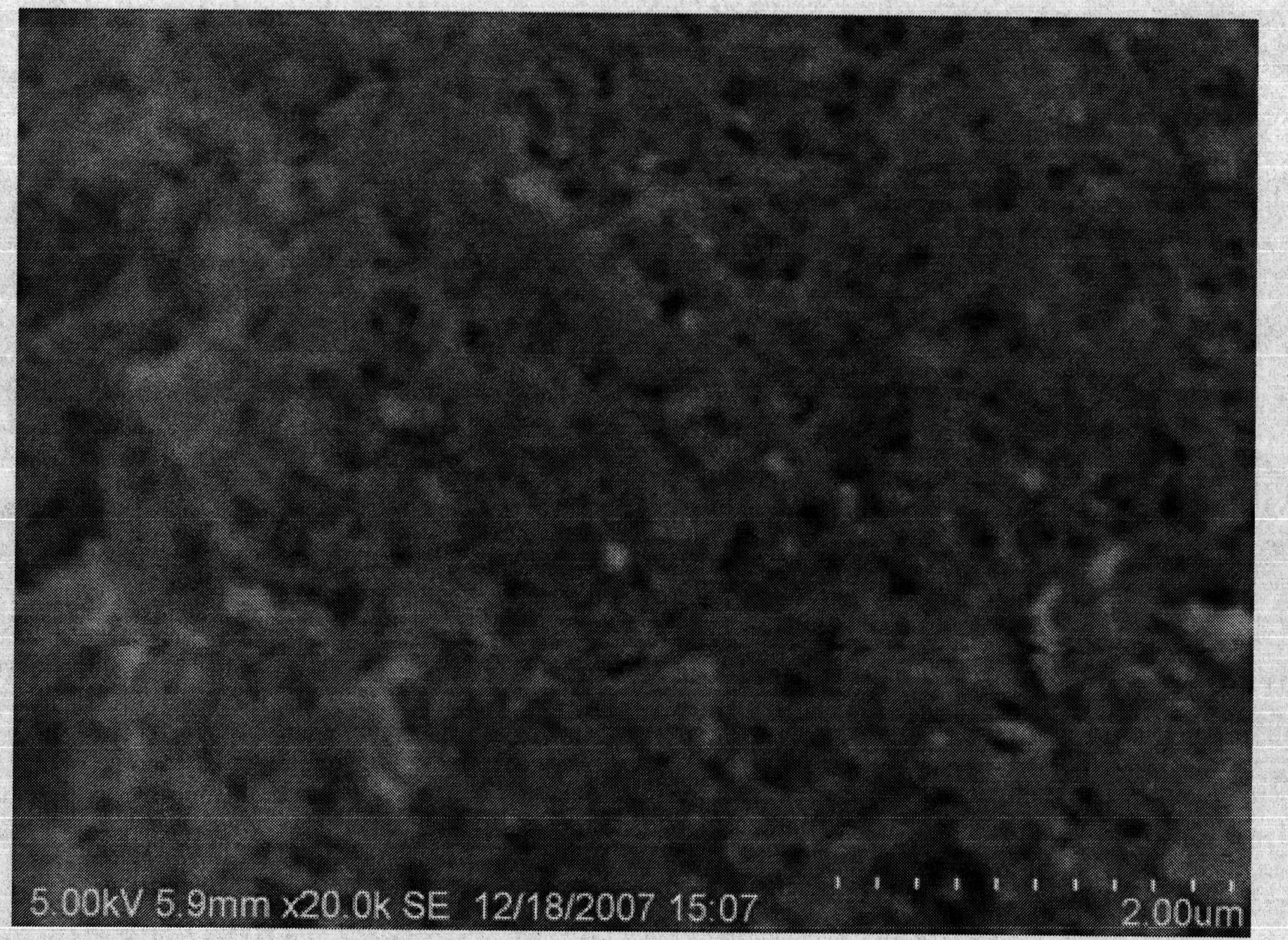

[0014] Specific embodiment three: utilize precipitation polymerization method to prepare the blank polymer that does not add chloramphenicol template molecule in the present embodiment and the preparation method is as follows: 1, 2mmol methacrylic acid is dissolved in 100mL acetonitrile, then in the shaking frequency is 110Hz Shake for 5 hours under the conditions, then add ethylene glycol dimethacrylate and azobisisobutyronitrile to obtain a mixture, and ultrasonically treat the mixture for 5 minutes at an ultrasonic frequency of 40KHz and an ultrasonic power of 150W, and then fill it with nitrogen to remove oxygen Seal; 2. Heat the sealed mixture in a constant temperature water bath at 60°C for 24 hours, then cool, centrifuge, and discard the supernatant to obtain a precipitate, and then dry the precipitate naturally; 3. Use the precipitate obtained in step 2 with Wash with 10% acetic acid methanol solution to remove residual monomers and cross-linking agents, then wash with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com