Load type carbon nano-fiber catalyst and application thereof

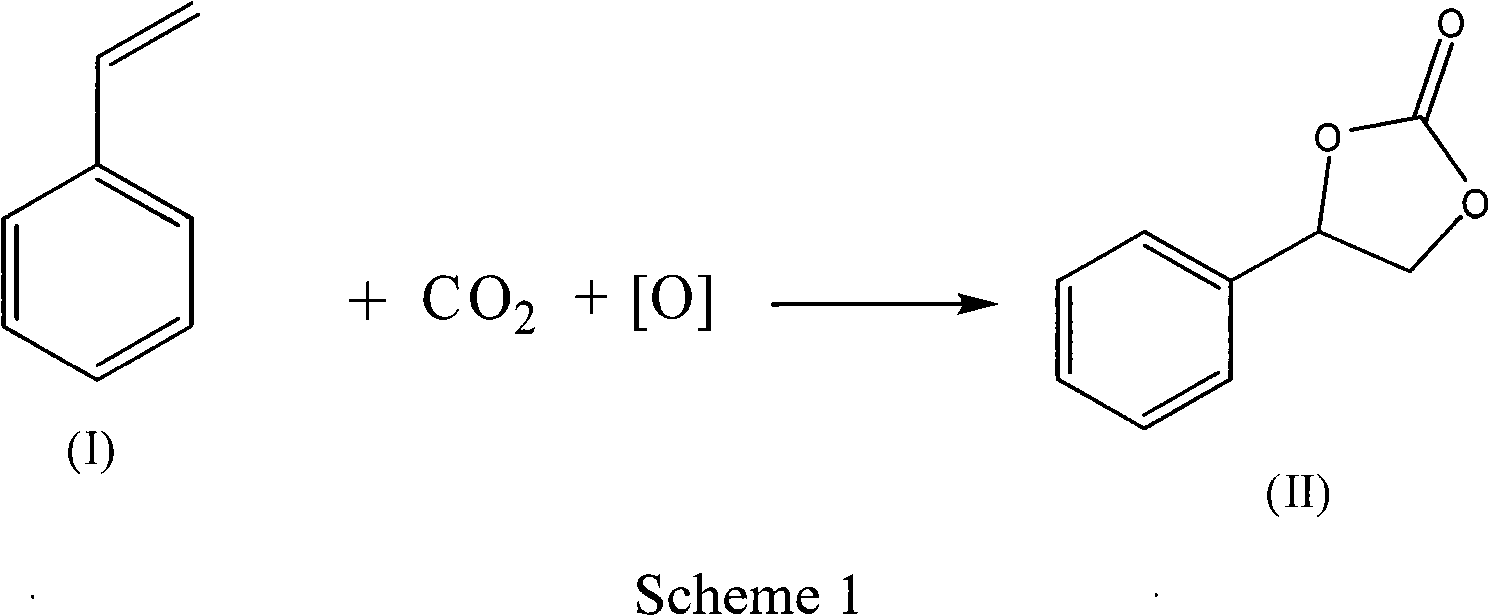

A carbon nanofiber and supported technology, which is applied in the field of green synthesis of styrene cyclic carbonate, can solve the problems of loss of gold elements, uneconomical and easy-to-obtain preparation raw materials, lower conversion rate and selectivity, etc., and achieve low production costs , engineering conditions are reasonable and easy to control, and the effect of high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of acetylacetonate vanadyl complex

[0030] Put 36.4g of vanadium pentoxide solid and equimolar acetylacetone in a three-necked flask to reflux for 20 hours, filter the suspension while hot, wash the solid product with acetone and ether, and dry at 110°C to obtain the green product vanadyl acetylacetonate complex [VO(C 5 h 7o 2 ) 2 ] (molecular weight 265.16).

Embodiment 2

[0031] Embodiment 2: the preparation of nickel acetylacetonate complex

[0032] 59.4g NiCl 2 .6H 2 O was dissolved in 150 mL of water (C solution), and 50 g of acetylacetone (0.5 mol) was dissolved in 100 mL of methanol (D solution). Add C to D and stir, then add 150 mL of aqueous solution containing 0.5 mol of sodium acetate (molecular weight: 136.08). The above mixture was reacted for 5 hours, kept in the refrigerator for several hours, filtered the green solid, washed with water, and dried at 110°C to obtain the nickel acetylacetonate complex [Ni(C 5 h 7 o 2 ) 2 ] (molecular weight 256.91).

Embodiment 3

[0033] Embodiment 3: surface oxidation treatment of carbon nanofibers

[0034] In a PTFE-lined autoclave, a mixture of concentrated nitric acid and concentrated sulfuric acid (volume ratio: 5:4) was used as an oxidant to treat CNF at 90 °C with constant temperature stirring for 1 h, and then it was washed with water, filtered and dried at 120 °C. overnight. The treated samples were designated as CNF90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com