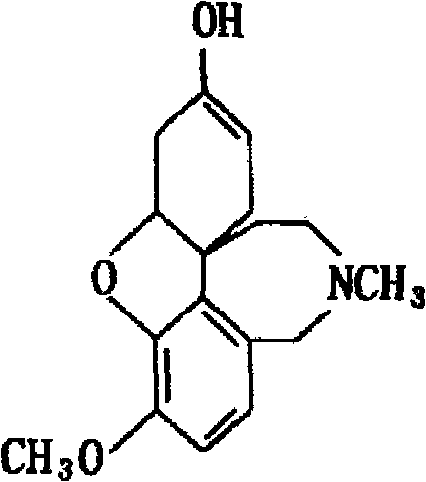

Preparation method of galanthamine

A technology of galantamine and chloroform, applied in the field of preparation of galantamine, can solve the problems of low galantamine content, unfavorable large production operation, large sewage discharge and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 10Kg of Lycoris bulb fine powder, add it into the triethylamine aqueous solution of pH=12, soak overnight, dry, place in CO 2 Supercritical extraction in supercritical extraction device, CO 2 The flow rate is 2ml / min / g crude drug, 90% ethanol aqueous solution is selected as the entrainer, the flow rate is 0.4ml / min / g crude drug, the extraction temperature is 60°C, the pressure is 30MPa, and the extraction time is 2h; the extract is dissolved by adding 2% hydrochloric acid aqueous solution, Filtrate, add CHCl to the filtrate 3 Extract, remove the lower layer, adjust the pH to 13, add CHCl 3 Extraction, take CHCl 3 Layer, separated by alumina chromatographic column, take chloroform-methanol-water (5:3:1) lower layer solution as eluent to elute, collect eluate, concentrate, add acetone-ethanol (1:1) Crystallized, washed and dried to obtain 213 mg of galantamine, which was detected by HPLC with a purity of 94.5%.

Embodiment 2

[0019] Take 10Kg of Lycoris bulb fine powder, add it to the ammonia solution of pH=10 and soak it overnight, dry it, and put it in CO 2 Supercritical extraction in supercritical extraction device, CO 2 The flow rate is 1ml / min / g crude drug, 90% ethanol aqueous solution is selected as the entrainer, the flow rate is 0.1ml / min / g crude drug, the extraction temperature is 20°C, the pressure is 10MPa, and the extraction time is 0.5h; the extract is dissolved by adding 2% hydrochloric acid aqueous solution , filtered, and the filtrate was added with CHCl 3 Extract, remove the lower layer, adjust the pH to 13, add CHCl 3 Extraction, take CHCl 3 layer, separated by alumina chromatographic column, take chloroform-methanol-water (4:5:1) lower layer solution as the eluent to elute, collect the eluate, concentrate, add acetone-ethanol (3:1) Crystallized, washed and dried to obtain 175 mg of galantamine, which was detected by HPLC with a purity of 92.3%.

Embodiment 3

[0021] Take 10Kg of Lycoris bulb fine powder, add it to the triethylamine aqueous solution of pH=13, soak overnight, dry, place in CO 2 Supercritical extraction in supercritical extraction device, CO 2 The flow rate is 5ml / min / g crude drug, 90% ethanol aqueous solution is selected as the entrainer, the flow rate is 0.8ml / min / g crude drug, the extraction temperature is 80°C, the pressure is 50MPa, and the extraction time is 4h; the extract is dissolved by adding 2% hydrochloric acid aqueous solution, Filtrate, add CHCl to the filtrate 3 Extract, remove the lower layer, adjust the pH to 13, add CHCl 3 Extraction, take CHCl 3 layer, separated by alumina chromatographic column, take chloroform-methanol-water (2:1:1) lower layer solution as the eluent to elute, collect the eluate, concentrate, add acetone-ethanol (1:6) Crystallized, washed and dried to obtain 235 mg of galantamine, which was detected by HPLC with a purity of 93.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com