Method for producing rare earth ion doped yttrium aluminum garnet nano phosphor powder

A technology of yttrium aluminum garnet and nano-fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, liquid injection devices, etc., and can solve problems such as harsh process requirements, irregular powder shapes, and large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

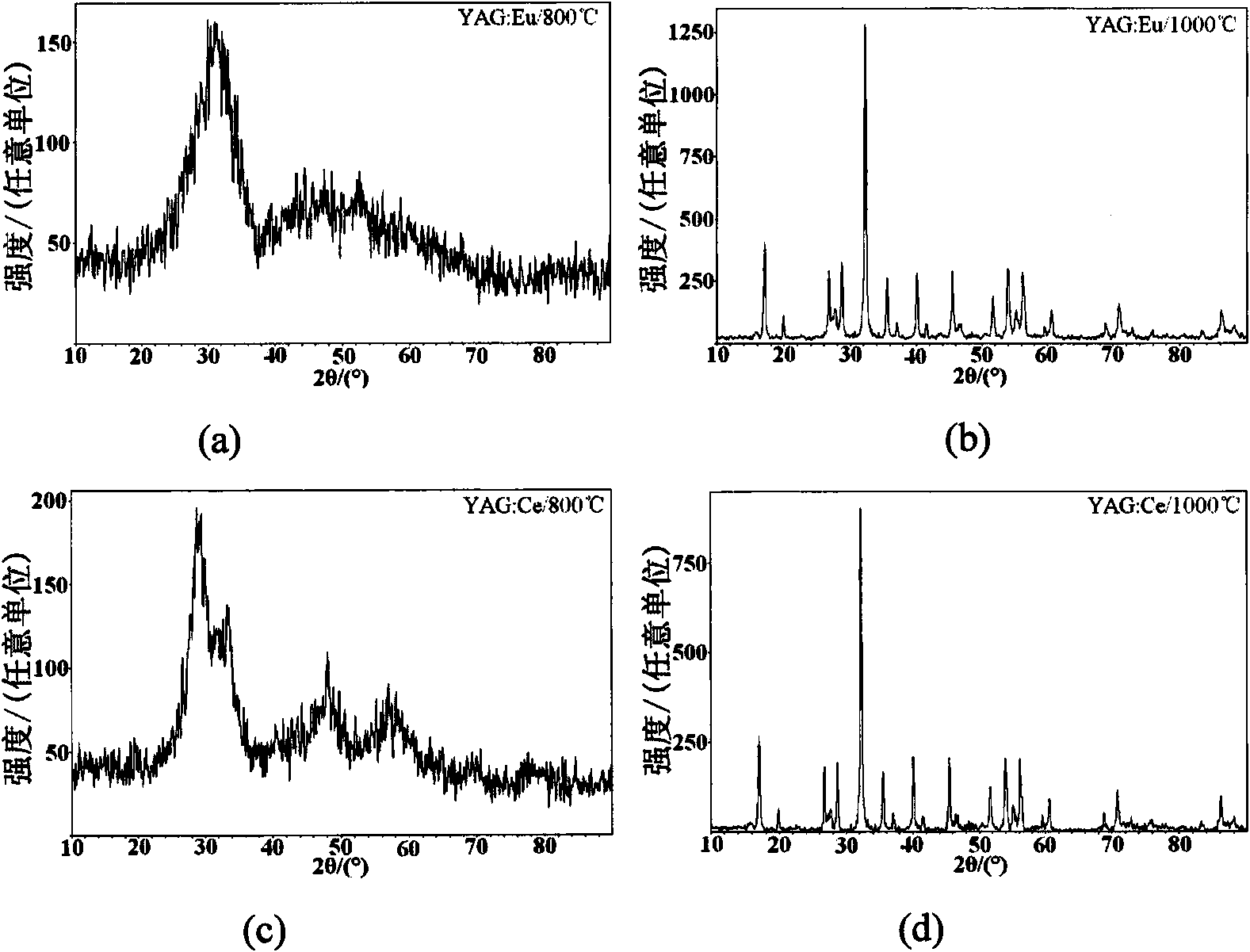

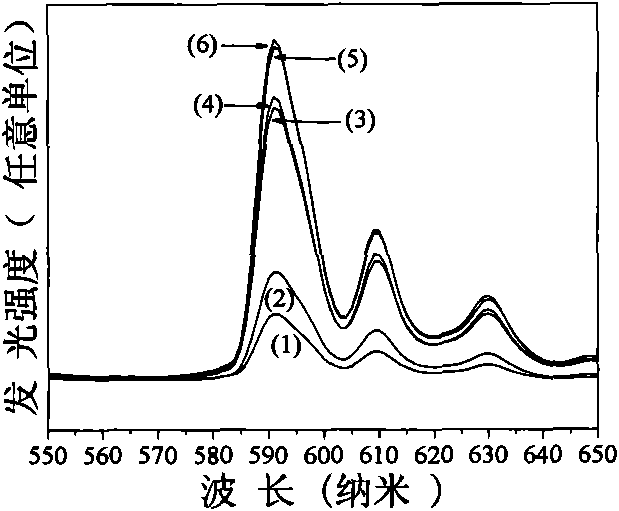

Embodiment 1

[0041] (1) First Al(NO 3 ) 3 , Y(NO 3 ) 3 and Eu(NO 3 ) 3 solution, according to the general formula (Y 0.98 Eu 0.02 ) 3 al 5 o 12 The stoichiometric ratio is formulated into a mother salt solution with a cation concentration of 0.2 mol / liter, and then a 0.6 mol / liter ammonium bicarbonate solution is prepared with deionized water, and the pH of the solution is adjusted to 10 with ammonia water, NH 4 HCO 3 The molar mass of (Y 1-χ ln χ ) 3 al 5 o 12 The ratio of the total molar weight of cations in the medium is 3:1;

[0042] (2) Adjust the valve so that the mother salt solution flows through the titanium alloy ultrasonic spray head with a pore size of 0.20 mm, and enters the ultrasonic atomization device at a flow rate of 300 ml / hour, and controls the spray flow rate so that the reaction is completed within 4 hours, at a frequency of 50KHz , Under the action of continuous ultrasound with a power of 45W, after ultrasonic atomization, it is added to the continuou...

Embodiment 2

[0048] (1) First Al(NO 3 ) 3 , Y(NO 3 ) 3 and Ce(NO 3 ) 3 solution, according to the general formula (Y 0.96 Ce 0.04 ) 3 al 5 o 12 The stoichiometric ratio is made into a mother salt solution with a cation concentration of 0.3 mol / liter, and then a 0.9 mol / liter ammonium bicarbonate solution is prepared with deionized water, and the pH of the solution is adjusted to 10 with ammonia water, NH 4 HCO 3 The molar mass of (Y 1-χ ln χ ) 3 al 5 o 12 The ratio of the total molar weight of cations in the medium is 3:1;

[0049] (2) Adjust the valve so that the mother salt solution flows through the titanium alloy ultrasonic spray head with a pore size of 0.20 mm, and enters the ultrasonic atomization device at a flow rate of 300 ml / hour, and controls the spray flow rate so that the reaction is completed within 4 hours, at a frequency of 50KHz , Under the action of continuous ultrasound with a power of 45W, after ultrasonic atomization, it is added to the continuously st...

Embodiment 3

[0055] (1) First Al(Ac) 3 、Y(Ac) 3 and Eu(Ac) 3 solution, according to the general formula (Y 0.94 Eu 0.06 ) 3 al 5 o 12 The stoichiometric ratio is made into a mother salt solution with a cation concentration of 0.15 mol / liter, and then a 0.45 mol / liter ammonium bicarbonate solution is prepared with deionized water, and the pH of the solution is adjusted to 10 with ammonia water, NH 4 HCO 3 The molar mass of (Y 1-χ ln χ ) 3 al 5 o 12 The ratio of the total molar weight of cations in the medium is 3:1;

[0056](2) Adjust the valve so that the mother salt solution flows through the titanium alloy ultrasonic spray nozzle with a pore size of 0.20 mm, and enters the ultrasonic atomization device at a flow rate of 200 ml / hour, and controls the spray flow rate so that the reaction is completed within 4 hours, at a frequency of 50KHz , Under the action of continuous ultrasound with a power of 45W, after ultrasonic atomization, it is added to the continuously stirring mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com