Catalyst for removing dioxin-type halogenated aromatic compounds and preparation method thereof

A dioxin and catalyst technology, which is applied in the field of catalysts for removing dioxin-like aromatic halogenated compounds and their preparation fields, can solve problems such as air pollution, achieve high conversion rate, high removal efficiency and easy The effect of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a 50ml ball mill jar, add 0.04 grams of ammonium metavanadate (NH4VO 3 ), 6 grams of manganese carbonate (MnCO 3 ) and 32.36 grams of anatase titanium dioxide (TiO 2 ), on a QM-C1300 planetary ball mill, after 300r / min ball milling for 3h, calcined at 600°C in air for 1h, and then the calcined mixture and 0.04 g of multi-walled carbon nanotubes (CNTs), 300r / min ball milled for 1h , to obtain vanadium-manganese / titanium oxide-multi-walled carbon nanotube catalyst [V-Mn / TiO 2 -CNTs], the catalyst contains (weight percent): 0.1% of vanadium, 15% of manganese, 0.1% of carbon nanotubes, and 84.8% of titanium oxide.

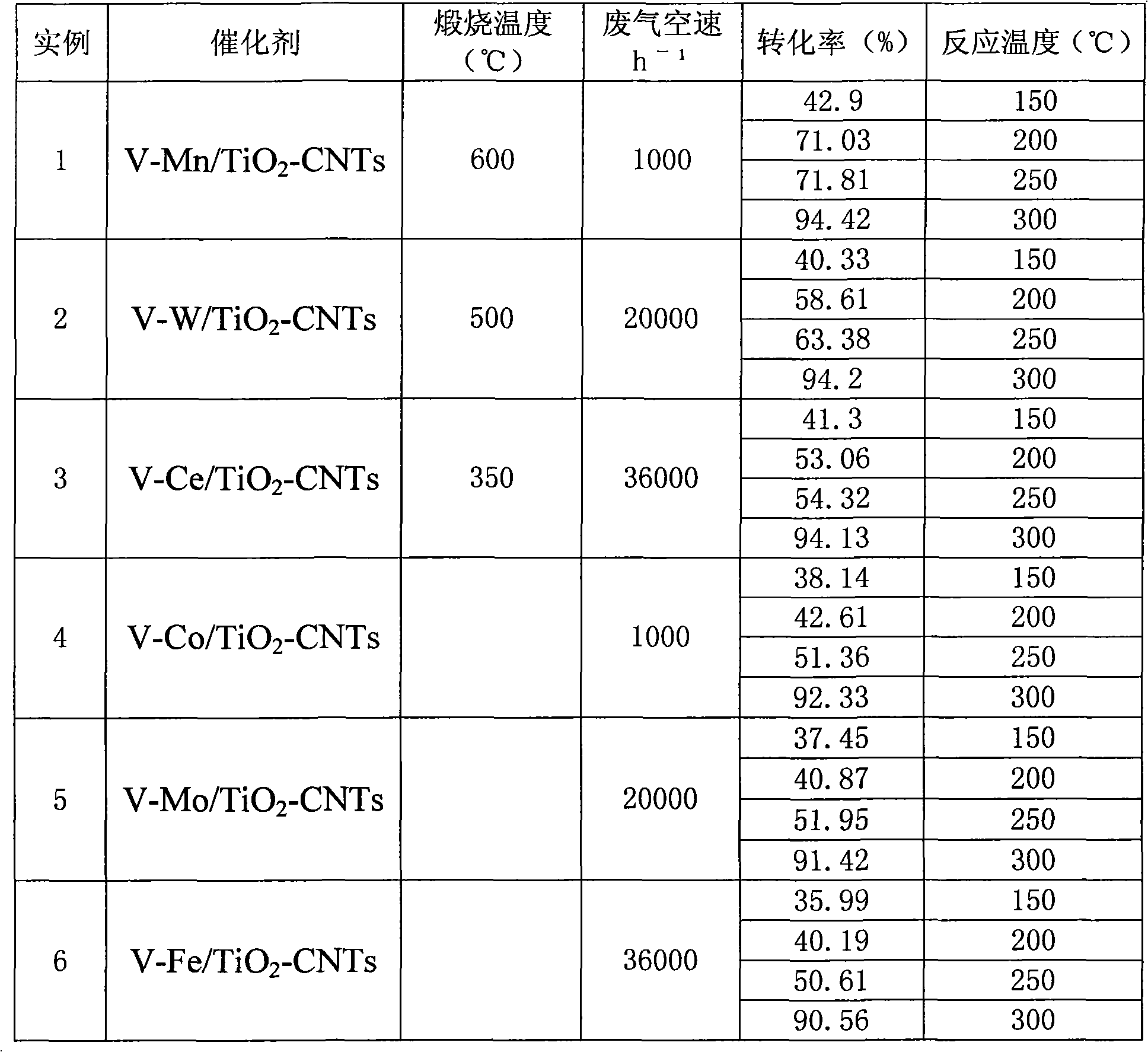

[0018] The conversion rate of this catalyst to remove chlorobenzene is shown in Table 1.

Embodiment 2

[0020] In a 50ml ball mill jar, add 2 grams of ammonium metavanadate (NH4VO 3 ), 4 grams of ditungsten trioxide (W 2 o 3 ) and 32.4 grams of anatase titanium dioxide (TiO 2 ), on a QM-C 1300 planetary ball mill, after 300r / min ball milling for 3h, calcined in air at 500°C for 3h, and then the calcined mixture and 1.6 g of multi-walled carbon nanotubes (CNTs), 300r / min ball mill 2h, the vanadium-tungsten / titanium oxide-multi-walled carbon nanotube catalyst [V-W / TiO 2 -CNTs], the catalyst contains (percentage by weight): 5% vanadium, 10% tungsten, 4% carbon nanotubes, and 81% titanium oxide.

[0021] The conversion rate of this catalyst to remove chlorobenzene is shown in Table 1.

Embodiment 3

[0023] In a 50ml ball mill jar, add 2.4 grams of ammonium metavanadate (NH4VO 3 ), 0.4 grams of cerium oxide (CeO 2 ) and 35.6 grams of anatase titanium dioxide (TiO 2 ), on a QM-C1300 planetary ball mill, after ball milling at 300r / min for 3h, calcining at 350°C in air for 5h, and then the calcined mixture and 4 grams of multi-walled carbon nanotubes (CNTs), ball milling at 300r / min for 3h , to obtain vanadium-cerium / titanium oxide-multi-walled carbon nanotube catalyst [V-Ce / TiO 2 -CNTs], the catalyst contains (weight percent): 6% of vanadium, 1% of cerium, 10% of carbon nanotubes, and 83% of titanium oxide.

[0024] The conversion rate of this catalyst to remove chlorobenzene is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com