Preparation method of cobaltates nanowire array with spinel structure

A spinel structure and nanowire array technology, which is applied in the field of preparation of cobaltate nanowire arrays, can solve the problem of uneven distribution of multi-element metal oxide composition, low filling rate of oxide precursors, and difficulty in phase purity, etc. problems, to achieve the effect of uniform pore size, controllable structure and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

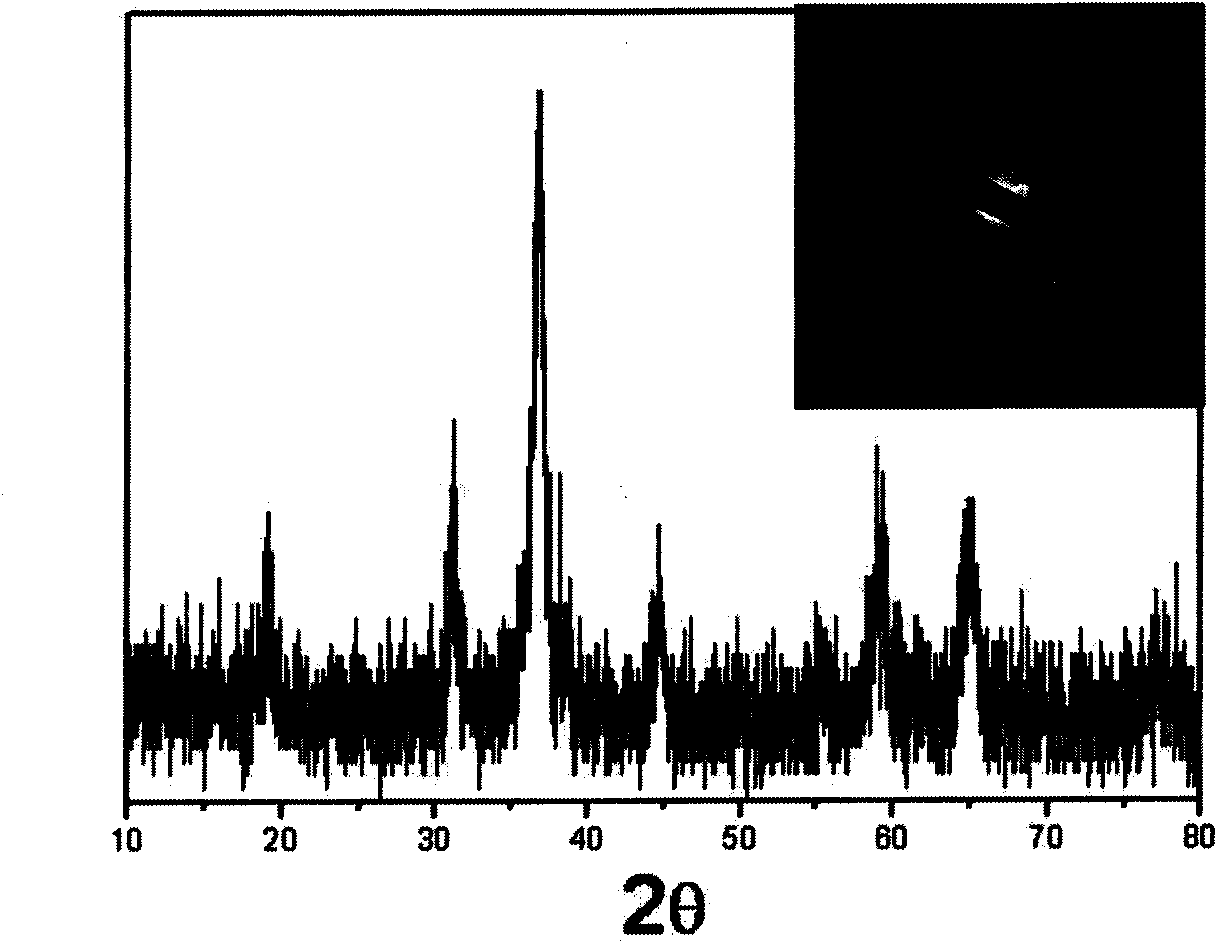

[0026] Synthesis of copper cobaltate nanowire arrays with spinel structure: firstly, copper nitrate trihydrate (Cu(NO) 2 ·3H 2 O) and cobalt nitrate hexahydrate (Co(NO) 2 ·6H 2 O) Formulated with a molar ratio of 1:2 (Cu / Co) to a concentration of about 1g ml -1 Aqueous solution. Disperse 0.5g of the calcined mesoporous silica SBA-15 uniformly in 20ml of n-hexane, stir at room temperature for 3 hours, then take 0.5ml of the prepared metal nitrate aqueous solution and add it dropwise with vigorous stirring; stir; Volatilize the solvent for 12-24 hours to obtain a dry powder; place the composite material in a muffle furnace and calcinate at 380°C for 4-6 hours to decompose the metal nitrate to produce copper cobaltate (CuCo) with a spinel structure. 2 O 4 ); Finally, the silica template was removed with 20ml of 2M sodium hydroxide (NaOH) aqueous solution and stirred at room temperature for 24 hours. The product is separated by centrifugation, washed and dried to obtain a crystallized...

Embodiment 2

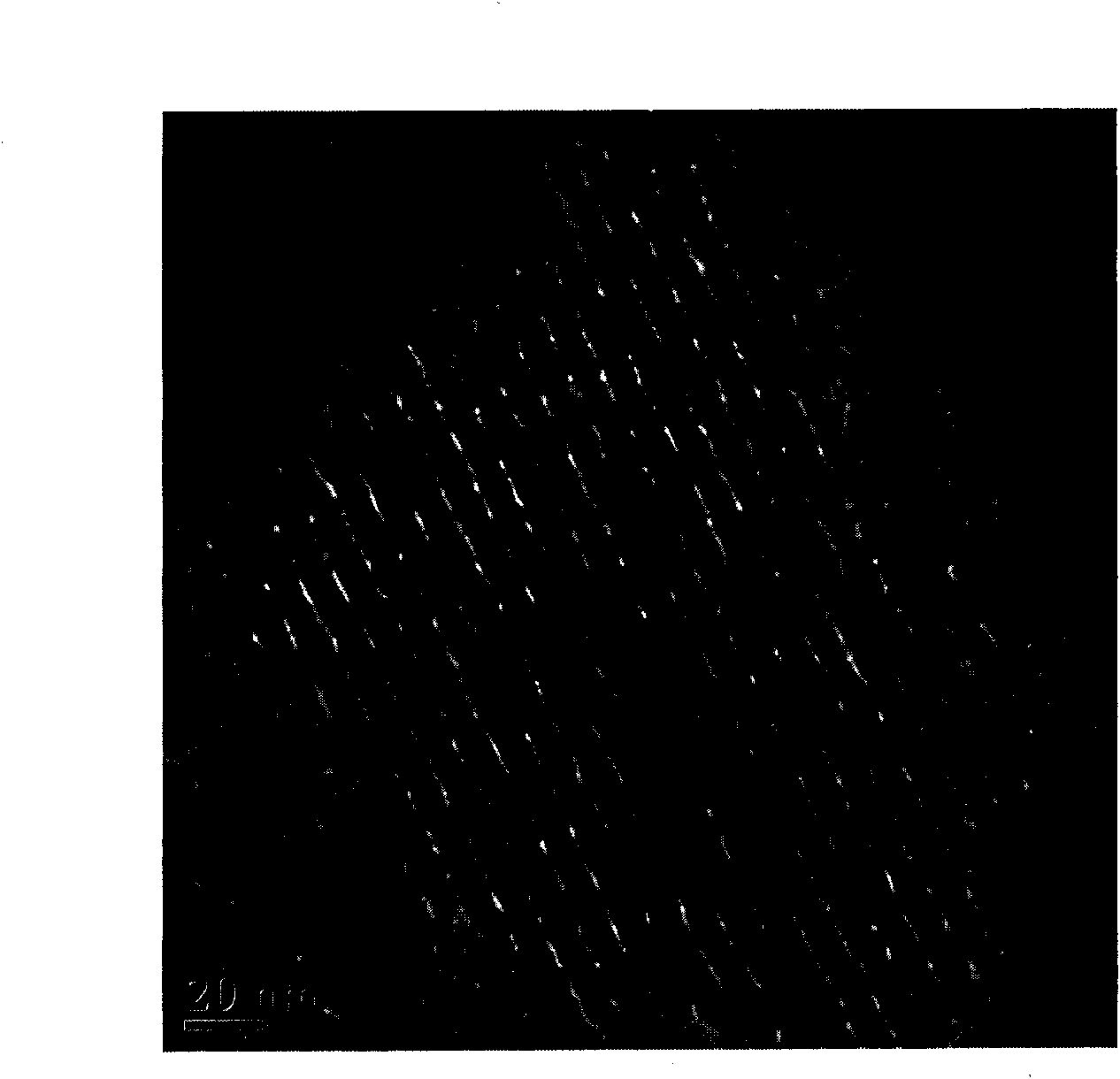

[0029] Synthesis of manganese cobaltate nanowire arrays with spinel structure: First, the manganese nitrate aqueous solution (Mn(NO) 2 , 50wt%) and cobalt nitrate hexahydrate (Co(NO) 2 ·6H 2 O) Formulated with a molar ratio of 1:2 (Mn / Co) to a concentration of about 1g ml -1 Aqueous solution. Disperse 0.5g of the calcined mesoporous silica SBA-15 uniformly in 20ml of n-hexane, stir at room temperature for 3 hours, then take 0.5ml of the prepared metal nitrate aqueous solution and add it dropwise with vigorous stirring; stir; Volatilize the solvent for 12-24 hours to obtain a dry powder; place the composite material in a muffle furnace and calcinate at 380°C for 4-6 hours to decompose the metal nitrate to produce manganese cobaltate (MnCo) with a spinel structure. 2 O4 ); Finally, the silica template was removed with 20ml of 2M sodium hydroxide (NaOH) aqueous solution and stirred at room temperature for 24 hours. The product is separated by centrifugation, washed and dried to obtai...

Embodiment 3

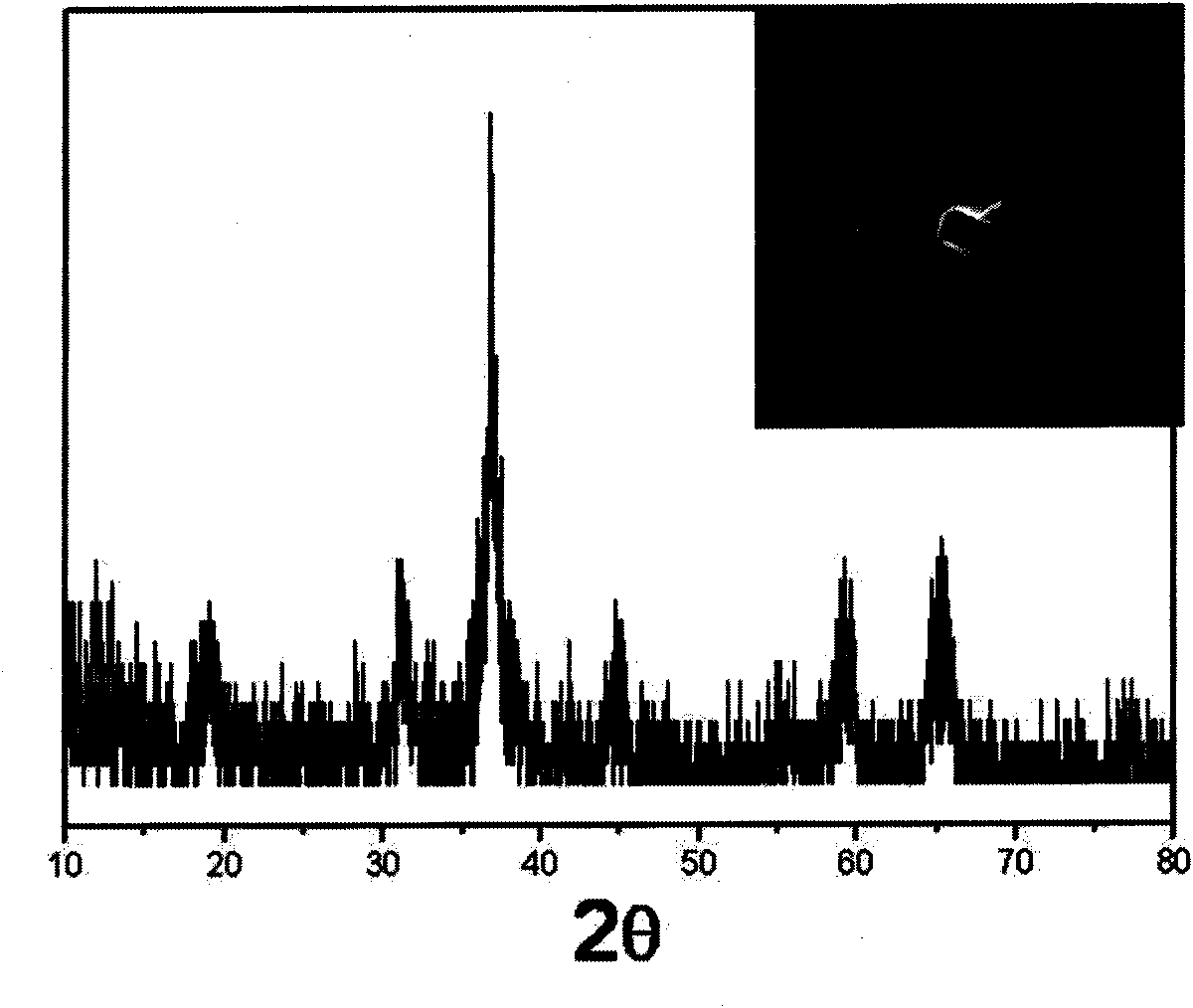

[0032] Synthesis of nickel cobaltate nanowire arrays with spinel structure: firstly, nickel nitrate hexahydrate (Ni(NO) 2 ·6H 2 O) and cobalt nitrate hexahydrate (Co(NO) 2 ·6H 2 O) Formulated with a molar ratio of 1:2 (Ni / Co) to a concentration of about 1g ml -1 Aqueous solution. Disperse 0.5g of the calcined mesoporous silica SBA-15 uniformly in 20ml of n-hexane, stir at room temperature for 3 hours, then take 0.5ml of the prepared metal nitrate aqueous solution and add it dropwise with vigorous stirring; stir; Volatilize the solvent for 12-24 hours to obtain a dry powder; place the composite material in a muffle furnace and calcinate at 380°C for 4-6 hours to decompose the metal nitrate to form nickel cobaltate (NiCo) with a spinel structure. 2 O 4 ); Finally, the silica template was removed with 20ml of 2M sodium hydroxide (NaOH) aqueous solution and stirred at room temperature for 24 hours. The product is separated by centrifugation, washed and dried to obtain a crystallized n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com