Preparation method of amino polyphosphazene microspheres

A technology of amino polyphosphazene and microspheres is applied in the field of preparation of amino polyphosphazene microspheres, and can solve the problems of being unsuitable for large-scale production, difficult to remove dispersants or surfactants, complicated chemical synthesis steps, and the like, Achieve high thermal stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 250 ml flask, 0.32 g of hexachlorocyclotriphosphazene (HCCP) was dissolved in 160 ml of acetonitrile solvent, then 0.6 g of 4,4'-diaminodiphenyl ether (ODA) and 4 ml of acid-binding agent Triethylamine (TEA) was added to the above solution, and reacted for 8 hours under the condition of 40° C. and 150 watts of ultrasound. After the reaction, the crude product is filtered, washed with acetone and water for 2-3 times, and dried in a vacuum oven for 7-8 hours to prepare the target amino microspheres.

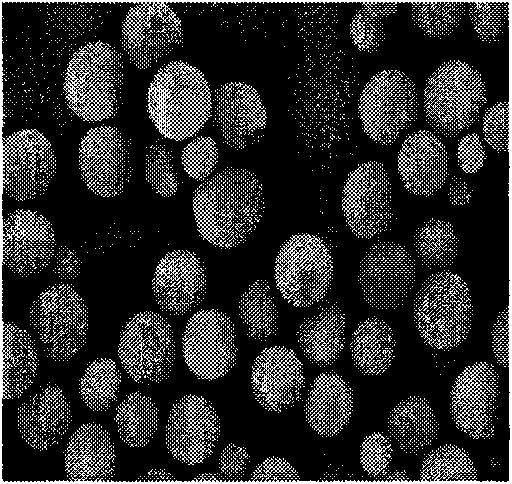

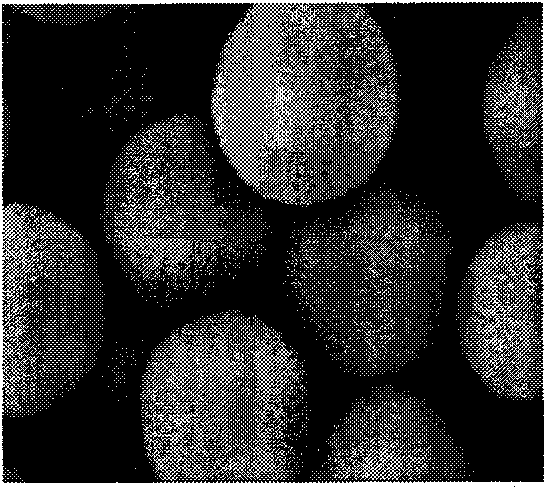

[0029] figure 1 , figure 2 It is the low magnification and high magnification scanning electron micrographs of the active microspheres prepared in Example 1. It can be seen from the photos that the surface of the microspheres is very clean, and there is no adhesion between the microspheres.

[0030] image 3 It is its transmission electron micrograph, and it can be known that the polymer microsphere has a solid structure.

[0031] Figure 4 It is the Fourier trans...

Embodiment 2

[0033] In a 250 ml flask, 0.32 g of hexachlorocyclotriphosphazene (HCCP) was dissolved in 110 ml of acetonitrile solvent, and then 0.6 g of 4,4'-diaminodiphenyl ether (ODA) and 4 ml of acid-binding The agent triethylamine (TEA) was added to the above solution, and reacted for 8 hours under the condition of 40 degrees and 150 watts of ultrasound. After the reaction, the crude product was filtered, washed with acetone and water for 2-3 times, and the product was dried in a vacuum oven for 7-8 hours to obtain functional amino microspheres with a clean surface (see Figure 5 ); the infrared spectrogram shows that its structure is 4,4-diaminodiphenyl ether and hexachlorocyclotriphosphazene cross-linked polycondensation structure.

Embodiment 3

[0035] In a 250 ml flask, 0.32 g of hexachlorocyclotriphosphazene (HCCP) was dissolved in 80 ml of acetonitrile solvent, and then 0.8 g of 4,4'-diaminodiphenyl ether (ODA) and 4 A milliliter of acid-binding agent triethylamine (TEA) was added to the above solution, and reacted for 8 hours under the condition of 40 degrees and 150 watts of ultrasound. After the reaction, the crude product was filtered, washed with acetone and water for 2-3 times, and after the product was dried in a vacuum oven for 7-8 hours, the functional amino microspheres with a clean surface (see Image 6 ); the infrared spectrogram shows that its structure is 4,4-diaminodiphenyl ether and hexachlorocyclotriphosphazene cross-linked polycondensation structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com