Derivative of macrolides, method for preparing same and application thereof

A technology of macrolides and derivatives, which is applied in the field of medicine to achieve good dissolution performance and improve bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

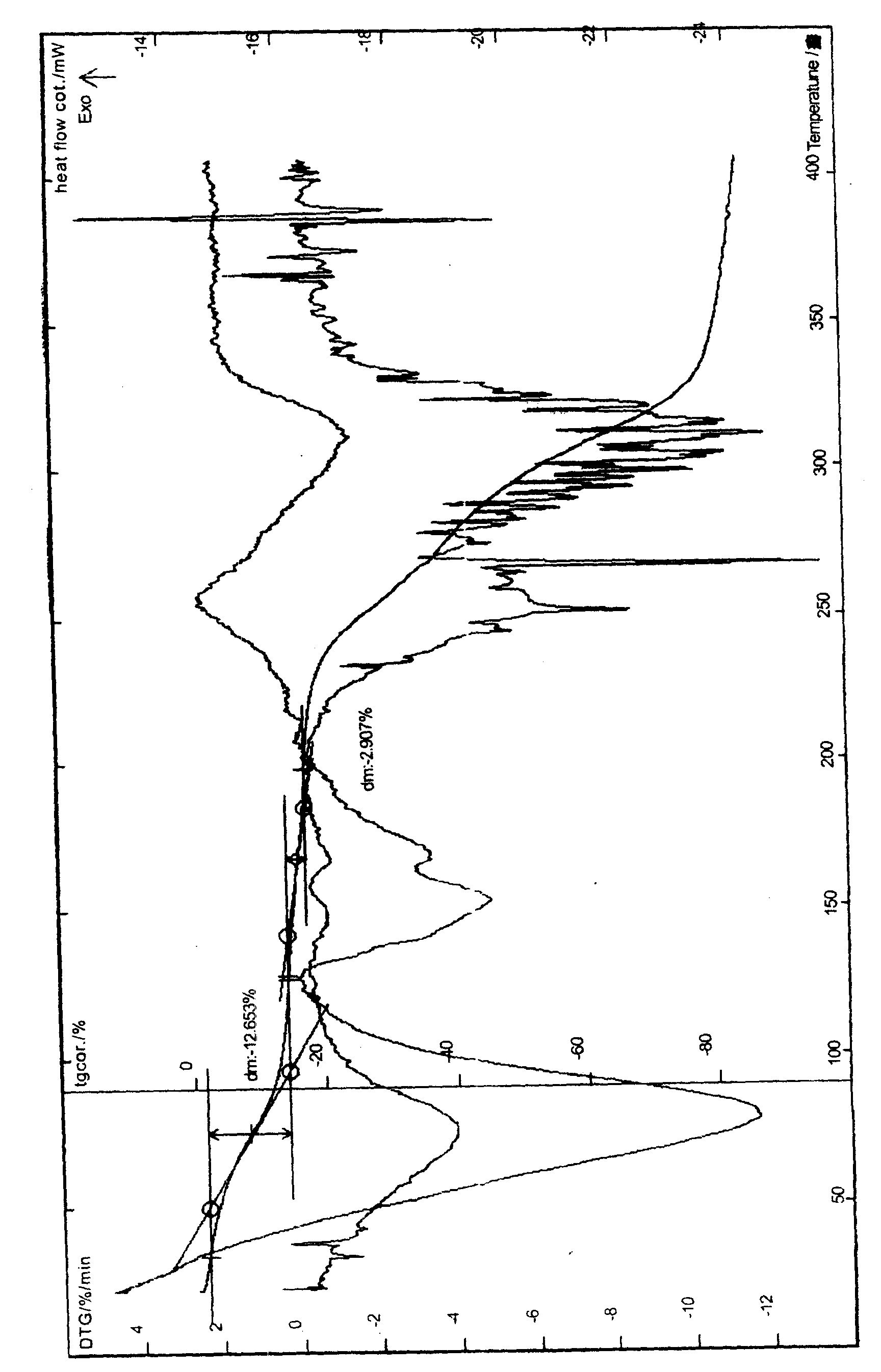

[0064] Example 1 Preparation of erythromycin lactobionic acid 11 hydrate: In a three-necked flask, add 50ml of acetone and 8g of erythromycin, stir, add lactobionic acid or its aqueous solution, stir at 5-35°C, make the reaction complete, slowly add Anhydrous acetone, cooled to about -30~5℃, wait for the solid to precipitate, filter, rinse the solid with anhydrous acetone, and drain to obtain off-white crystalline powder, easily soluble in water, HPLC: the main peak of the sample and red The retention time of the main peak of the mycin reference substance is the same, and the content of erythromycin is 56.79% (56.88%); melting point: 95.1~116.3°C (uncorrected), moisture measured by Karl Fischer method is 15.53% (theoretical value 15.36%), TG: 200 The weight loss of the platform before ℃ is about 15.56% (see attached figure 1 ), MS (ESI) m / z: 1092,734,358. Elemental analysis measured values: C 45.73, H 8.54, N 1.15; theoretical values: C 45.61, H 8.67, N 1.09.

Embodiment 2

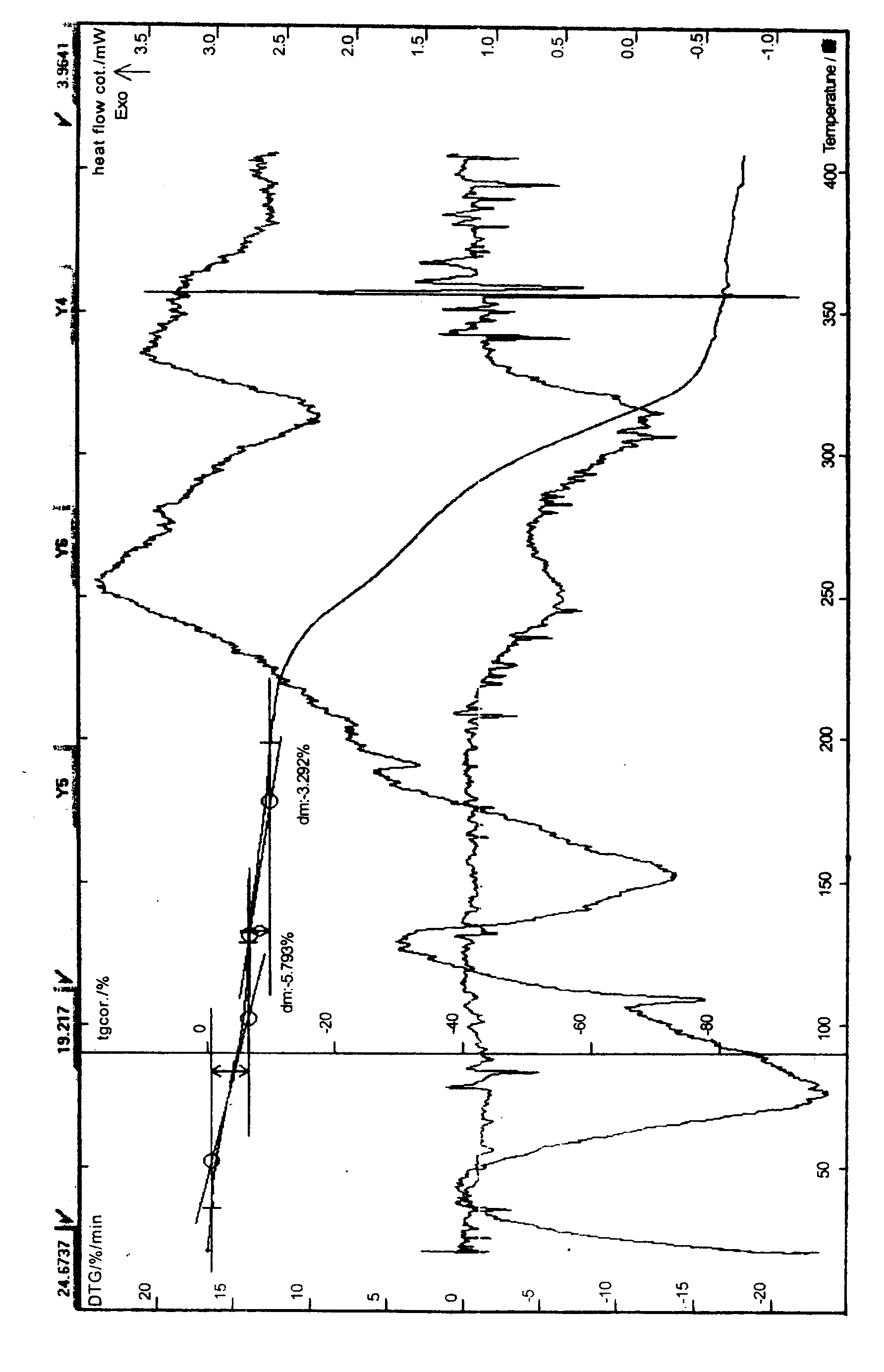

[0065] Example 2 Preparation of erythromycin lactobionic acid hexahydrate: In a three-necked flask, add 50 ml of acetone, 10 g of erythromycin, add equimolar lactobionic acid or its acetone aqueous solution under stirring at 10 to 40 ° C, and react for 0.2 to 4 Hours, after the reaction is complete, slowly add 1 to 8 times the amount of anhydrous acetone, cool to -45 to -10°C, filter, rinse the solid with acetone, drain, and dry at about 80°C to obtain off-white powder, very Soluble in water, HPLC: the retention time of the main peak of the sample is consistent with the main peak of the erythromycin reference substance, the content of erythromycin is 61.91% (theoretical 62.08%); melting point: 132.6-137.7°C (uncorrected); : 9.16%, TG: about 9.09% (theoretical value 9.01%) of platform weight loss before 200 ℃ (see attached figure 2 ), MS (ESI, FAB) m / z: 1092, 1091, 734, 733, 358, 357; elemental analysis measured values: C 49.11, H 8.55, N 1.21; theoretical values: C 49.03, H 8...

Embodiment 3

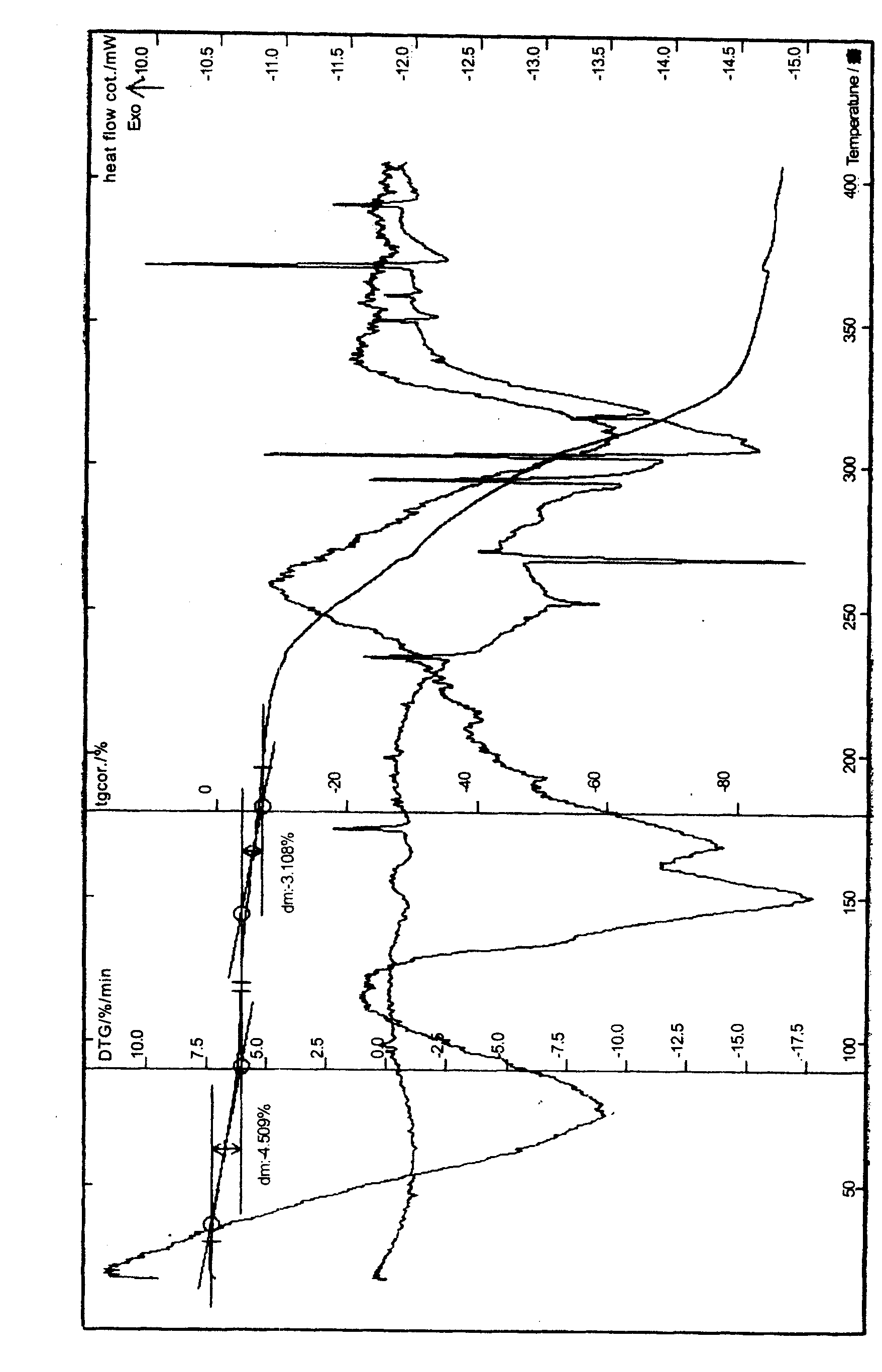

[0066] Example 3. Put 10 g of lactobionic acid and erythromycin in a molar ratio (1:1) into a reaction flask, add water, stir, and control the temperature between 5 and 40° C. to dissolve. After the reaction is completed, fill each bottle with 1 ml In a 20ml bottle, freeze it to -50°C, keep it for 0.5 to 6 hours, lower the temperature of the condenser to -55°C, vacuumize, and gradually raise the temperature to about -16°C through the shelf, then cool it down at about -16°C Keep it for about 28 hours, continue heating to raise the temperature of the drug to about 30°C, keep it for about 10 hours, and get a white powder with a yield of 99%. The sample is very soluble in water. HPLC: the retention of the main peak of the sample and the main peak of the erythromycin reference substance The time is the same; melting point: 137.2-138.7 ° C (uncorrected); Karl Fischer's method to determine the moisture is 4.67% (theoretical value 4.72%), TG-DTG: weight loss before 200 ° C is about 4.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com