Fluorine-containing resin emulsion and preparation method thereof

A technology of fluorine-containing resin and resin emulsion, which is applied in the field of fluorine-containing resin emulsion and its preparation, can solve the problems of organic solvents polluting the environment and increasing costs, and achieve the effect of good hydrophobic and oleophobic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

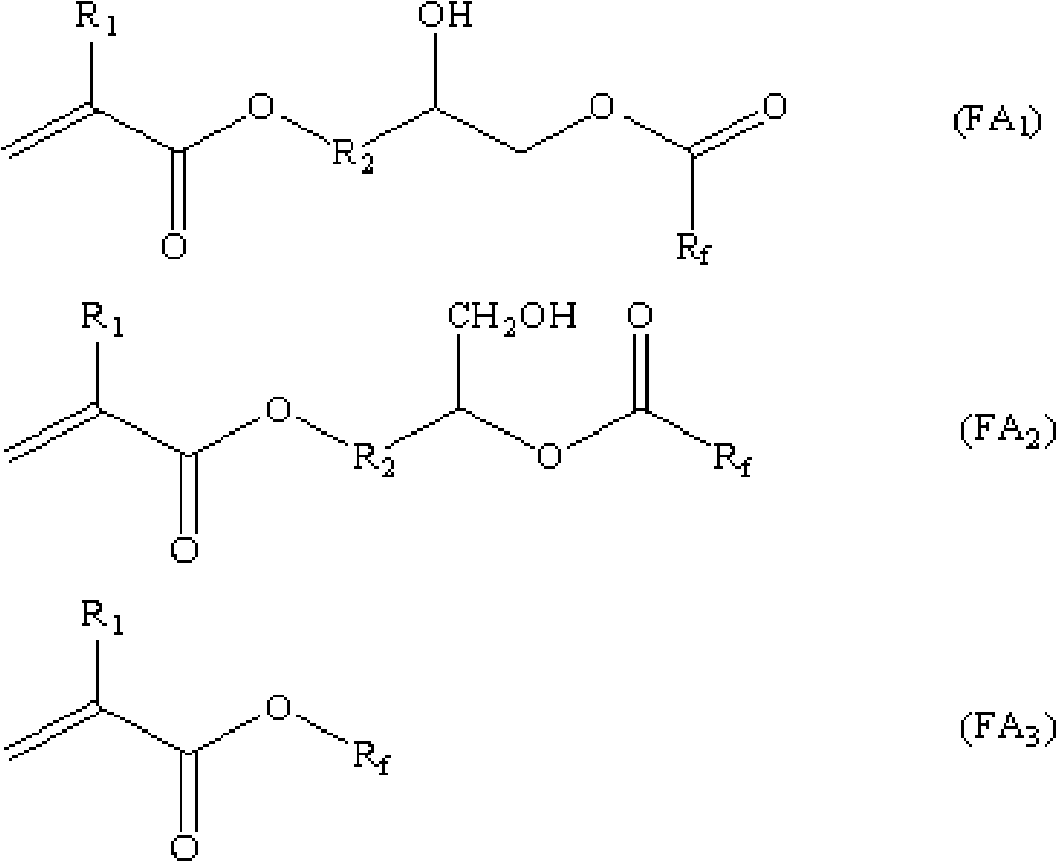

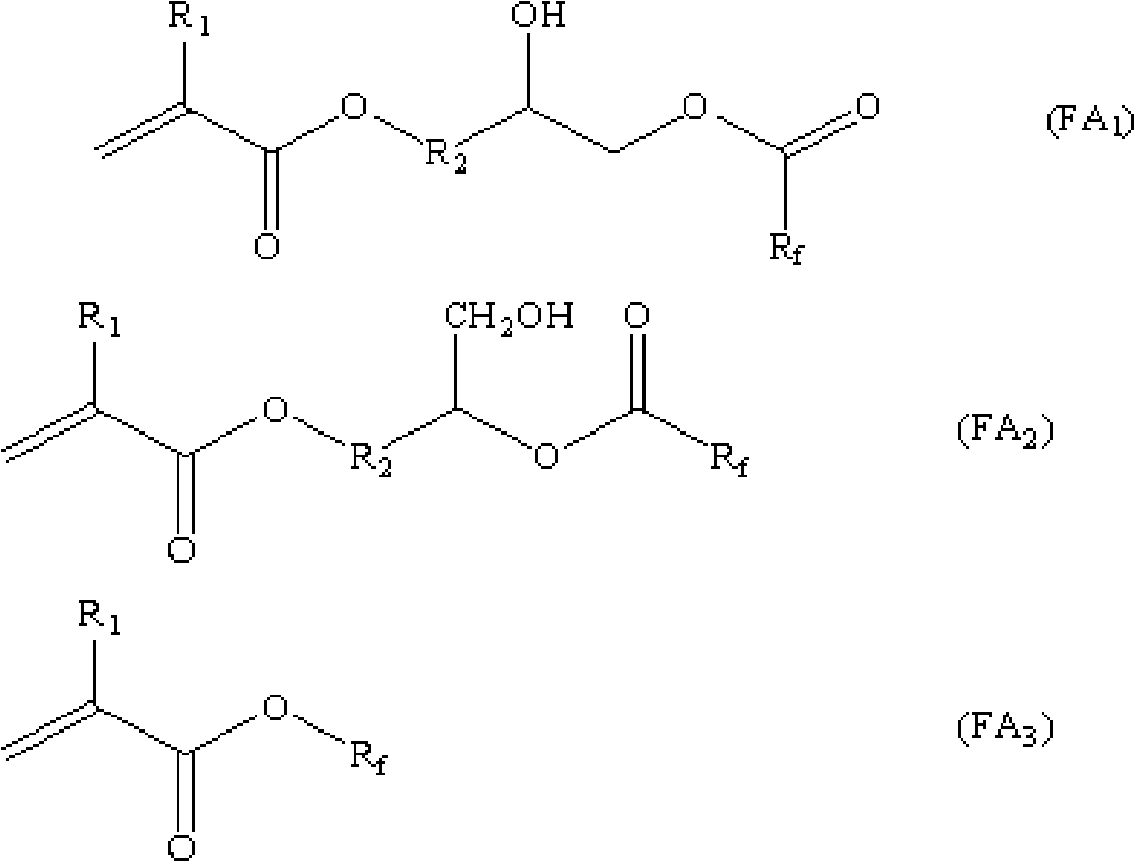

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: nuclear emulsion composition

[0026] Composition

[0027] Shell emulsion composition:

[0028] Composition

[0029] Preparation method: the reaction temperature is 50°C, first add part of the initiator into the four-neck flask, then add the nuclear pre-emulsion to it, and continue the reaction for 5 hours. Add the initiator and the shell pre-emulsion to the above-mentioned core seed emulsion at the same time, and continue to react for 0.5 hours to prepare a bluish fluorescent core-shell polymer emulsion, which can be formed into a film at room temperature after coating, and the static water contact angle is 109°.

Embodiment 2

[0030] Embodiment 2: nuclear emulsion composition

[0031] Composition

[0032] Shell emulsion composition:

[0033] Composition

[0034] Preparation method: Add 130ml of water containing part of the emulsifier into a four-necked flask equipped with a stirrer and a thermometer. The reaction temperature is 60°C, the stirring speed is about 200r / min, and nitrogen protection is used. After the temperature is balanced, add 9g of nuclear group After dividing the pre-emulsion (containing 0.21g ammonium persulfate and 0.17g sodium bisulfite), add 27g core component pre-emulsion (containing 0.31g ammonium persulfate) and 50ml of sodium bisulfite (0.0024g) solution, The temperature was maintained at 60° C. for 60 minutes to obtain a nuclear emulsion. Keeping the temperature of the reaction system constant, add 145g of shell component pre-emulsion (containing 0.19g of ammonium persulfate) and 80ml of sodium bisulfite (0.16g) solution to the obtained core emulsion, a...

Embodiment 3

[0035] Embodiment 3: nuclear emulsion composition

[0036] Composition

[0037] Shell emulsion composition:

[0038] Composition

[0039] Preparation method: Add 103ml of water containing part of the emulsifier to a four-necked flask equipped with a stirrer and a thermometer, add 0.2g of sodium bicarbonate and 73g of nuclear pre-emulsion (containing 0.005g of ammonium persulfate), and the reaction temperature is 80°C. Stirring speed is about 200r / min. Then, 7 g of nuclear pre-emulsion and 10 ml of sodium persulfate (containing 0.01 g) solution were added thereto under the protection of nitrogen, and the nuclear emulsion was obtained after reacting for 1 hour. Dissolve ammonium persulfate (0.5g) in 20ml of water, add 5g of the shell pre-emulsion to the above-mentioned core seed emulsion at the same time, react for 0.5 hours to prepare a core-shell polymer emulsion, and then add 2,4-toluene diisocyanate (5g) , That is, room temperature cross-linking type fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com