Preparation method of lithium iron phosphate as cathode material of lithium ion battery

A technology for lithium iron phosphate and lithium ion batteries, applied in the field of continuous preparation of lithium iron phosphate materials, can solve the problems of non-continuous discharge, long heating time, slow heat transfer, etc., to avoid huge waste of energy, good charging Discharge performance, effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

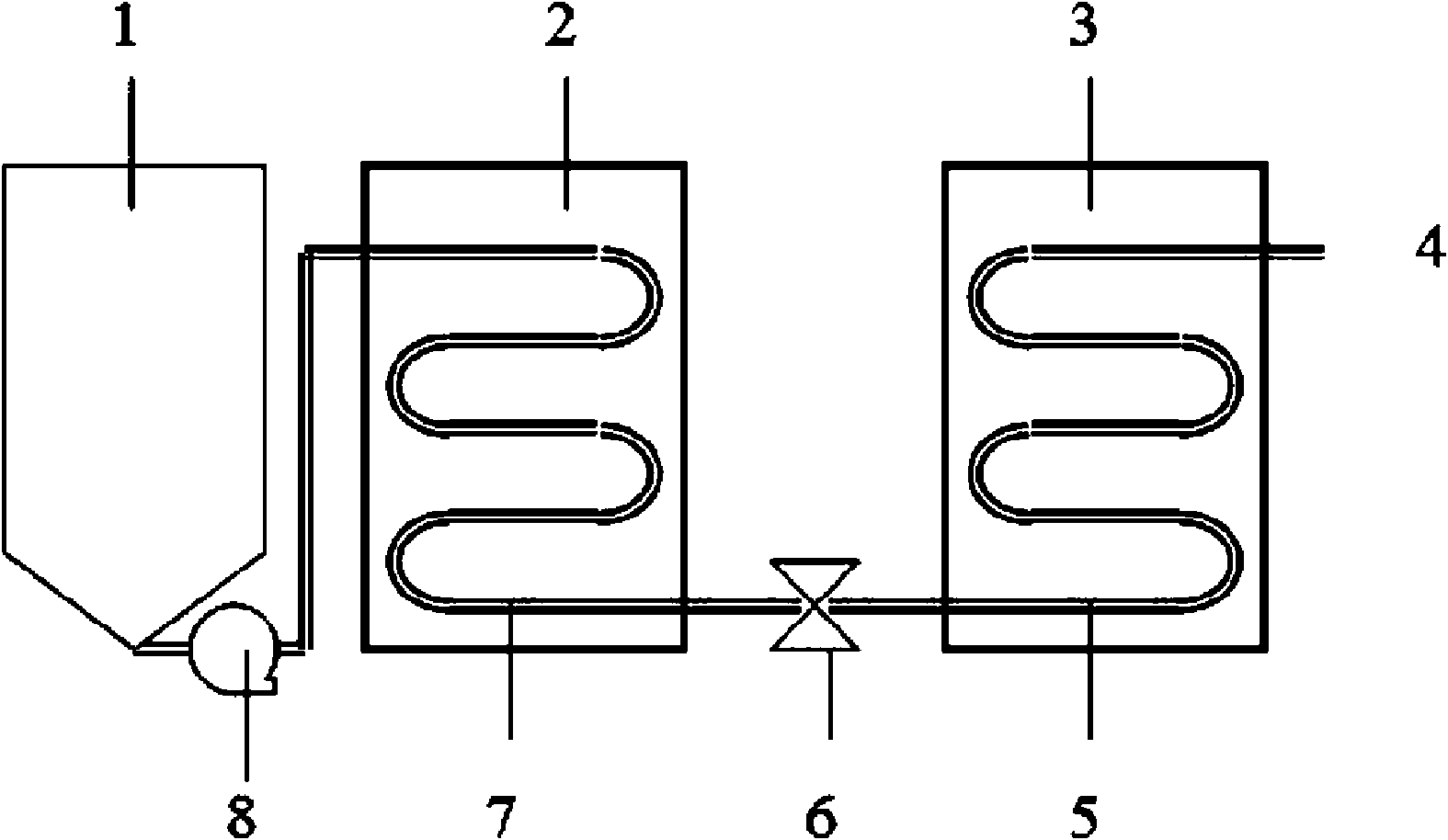

[0021] The preparation method of lithium iron phosphate lithium ion battery cathode material of the present invention comprises the following steps: mixing the reaction liquid uniformly and pressurizing, then passing through an externally heated heat pipe, utilizing the continuous flow of the liquid in the heat pipe and heating outside the heat pipe to make the reaction The raw materials are mixed, the crystals are nucleated, and grow up during the flow process to realize the continuous synthesis of lithium iron phosphate material. At the end of the reaction, after the liquid is cooled, filtered, washed, and dried, the finished product of lithium iron phosphate is obtained.

[0022] Such as figure 1 Shown, the present invention specifically comprises the following steps:

[0023] 1) Dissolve the analytically pure soluble ferrous salt, phosphoric acid source, and lithium source compound in high-speed stirred pure water in the batching tank 1 under the protection of an inert gas...

Embodiment 1

[0036] 277.85g of analytically pure ferrous sulfate heptahydrate, 111.76g of industrial phosphoric acid with a concentration of 85%, and 41.94g of lithium hydroxide monohydrate were dissolved in 10Kg of pure water stirred at high speed in a batching tank under nitrogen protection to form 0.1M of the mixture. After the obtained mixed solution was stirred for 0.5 h, it was pressed into the heat pipe by a high-pressure pump. After the liquid is pressurized, the pressure is 5Kg / cm 2 . The inner diameter of the heat pipe is 5mm, the material is corrosion-resistant austenitic stainless steel, and the length of the heating constant temperature zone is 100 meters. The inside of the heating container outside the heat pipe is maintained at 140°C. The flow rate of the final outlet is adjusted to 4.089 ml / min with a regulating valve, and the calculation shows that the heating process of the liquid in the heat pipe is 8 hours. After the liquid passes through the heat pipe, it passes th...

Embodiment 2

[0038] 91.3Kg of analytically pure ferrous chloride and 103.9Kg of lithium dihydrogen phosphate were dissolved in 1000Kg of pure water stirred at high speed in a batching tank under the protection of argon to form a 1M mixed aqueous solution. After the obtained mixed solution was stirred uniformly for 5 hours, it was pressed into the heat pipe by a high-pressure pump. After the liquid is pressurized, the pressure reaches 15Kg / cm 2 . The inner diameter of the heat pipe is 25mm, and the material is corrosion-resistant austenitic stainless steel. The length of the heating constant temperature zone is 20 meters. The inside of the heating container is maintained at 200°C, and the flow rate of the final outlet is adjusted to 81.77 ml / min with a regulating valve. It can be calculated that the heating process of the liquid in the heat pipe is 2 hours. The liquid enters the cooling pipe through the regulating valve after passing through the heat pipe. The liquid in the cooling pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com