Method for preparing cholesterol reducing eggnog fermenting drink by utilizing lactobacillus and microzyme which produce bile salt hydrolase

A bile salt hydrolysis enzyme and cholesterol-lowering technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, food preparation, etc., to achieve the effect of reducing cholesterol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

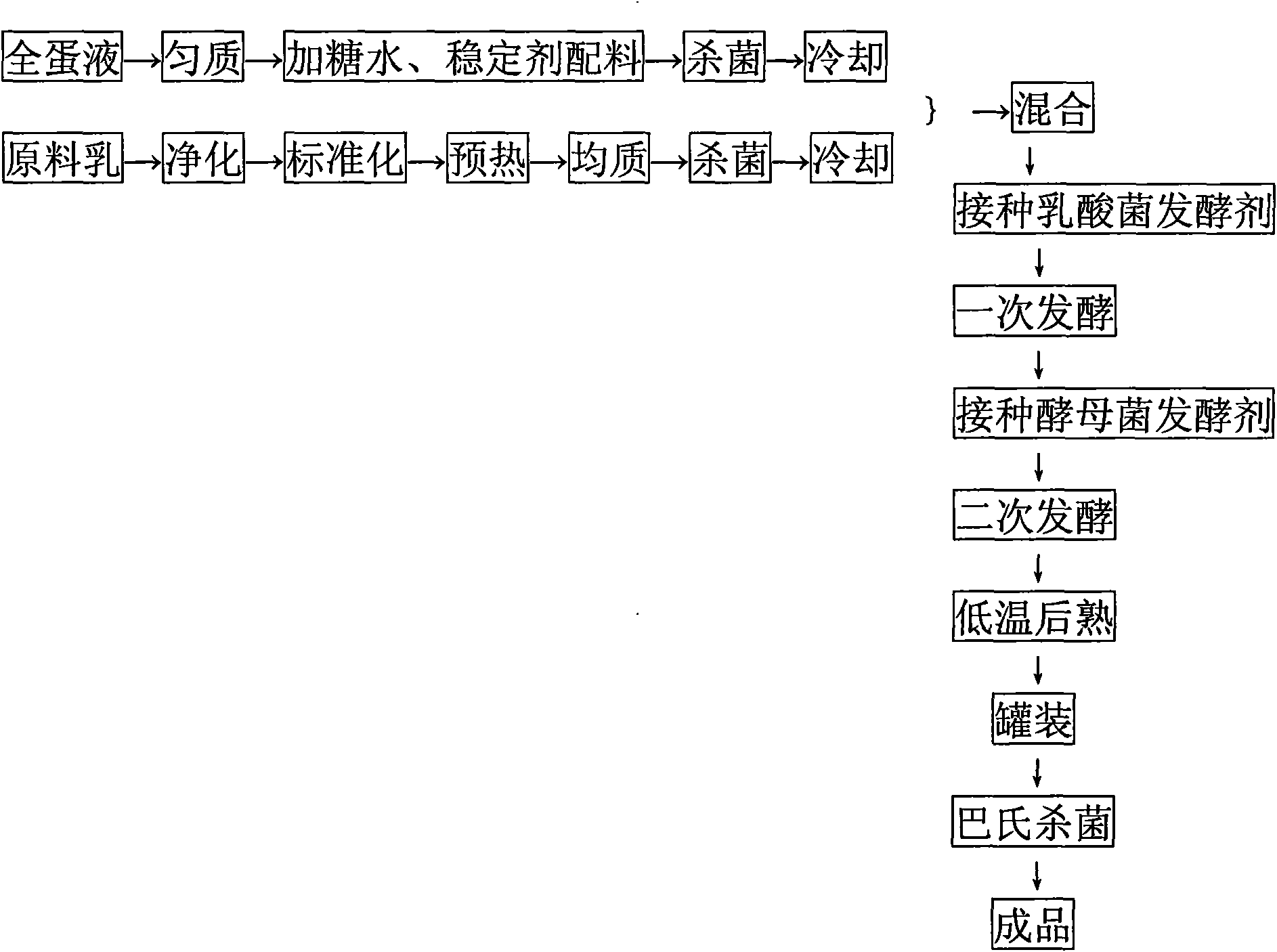

Method used

Image

Examples

Embodiment 1

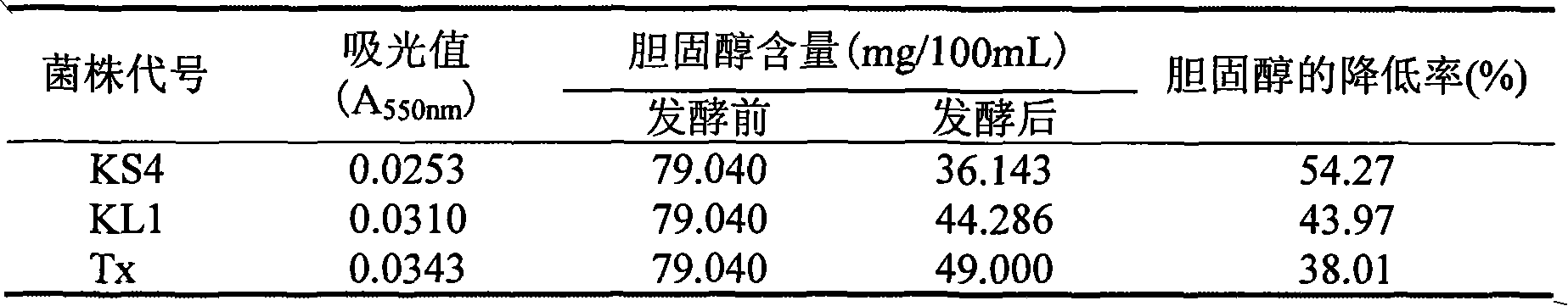

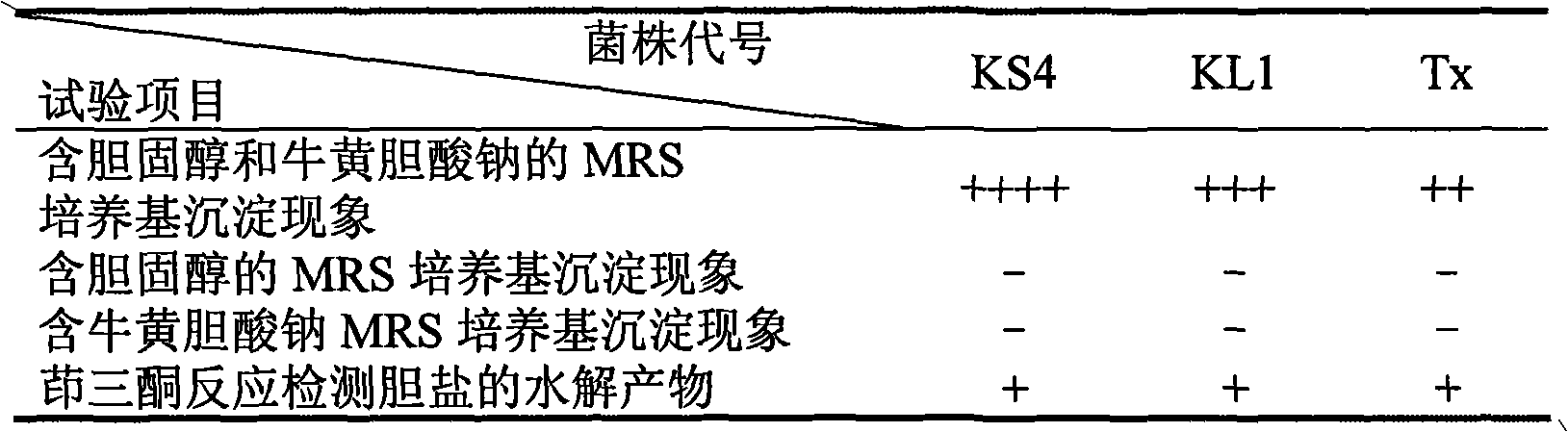

[0043] Embodiment 1, Lactobacillus casei (Lactobacilluscasei) KL1 of high-efficiency cholesterol-lowering and high-production bile salt hydrolase, Lactococcus lactis subspecies (Lactococcus lactis subsp. identification

[0044] 1. Screening of lactic acid bacteria strains with high cholesterol-lowering efficiency and high production of bile salt hydrolase

[0045] Take 5mL of the filtrate of Zangling mushroom and pour it into 45mL sterile saline with glass beads, shake it fully for 30min to make a bacterial suspension, and then dilute it 10 times to 10 -4 ~10 -6 diluted bacterial solution. Inoculate the plate with the dilution pouring method, pour into the MRS selective medium containing calcium carbonate and natamycin, incubate at 37°C for 24 hours, pick a single colony with a dissolution circle and inoculate it in the MRS slant medium, and incubate at 37°C Cultivate for 24h. Gram staining, depending on the individual shape and purity. Inoculate in MRS liquid medium, enr...

Embodiment 2

[0059] Example 2. Screening and Identification of Kluyveromyces marxianus K1 and M3 Strains with High Efficiency in Lowering Cholesterol and High Production of Bile Salt Hydrolase

[0060] 1. Screening of high-efficiency cholesterol-lowering and high-production bile salt hydrolase yeast strains

[0061] Take 5mL of the filtrate of Zangling mushroom and pour it into 45mL sterile saline with glass beads, shake it fully for 30min to make a bacterial suspension, and then dilute it 10 times to 10 -4 ~10 -6 diluted bacterial solution. The plates were inoculated by the dilution pouring method, poured into the potato lactose selective medium containing antibiotics, and cultured at 28°C for 2-3 days. According to the colony characteristics of the yeast and the results of microscopic examination of the water immersion slides, the target colonies on the above plate were streaked and inoculated on the corresponding slant medium, and cultured at 28°C for 2-3 days. Transfer to inoculate ...

Embodiment 3

[0075] Example 3, using three strains of lactic acid bacteria with high bile salt hydrolytic enzyme production and a yeast strain two-step fermentation method to prepare a cholesterol-lowering egg-milk fermented beverage

[0076] 1. Preparation of lactic acid bacteria single starter

[0077] Put 10mL of skim milk into a test tube, sterilize at 0.07Mpa for 20min, cool to 37°C, take 2~3 rings with spiral inoculation loops, and inoculate Lactobacillus casei KL1 producing bile salt hydrolyzing enzyme and Lactococcus lactis subsp. KS4, a preserved strain of Streptococcus thermophilus Tx skim milk, was cultured at 37°C until the milk coagulated, and activated for 2 to 3 generations. Transfer the above-mentioned activated strains to 10ml sterile skim milk with 1%-2% inoculation amount, culture overnight at 37°C until the milk coagulates, then transfer to 200ml sterilized milk with 2%-3% inoculum amount Cultivate in a triangular flask at 37°C until the milk coagulates, which is a sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com