Preparation method of carbon nano tube/polyaniline netty compound material

A technology of carbon nanotubes and composite materials, applied in the fields of fibrous fillers, chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of short service life, small specific capacity, specific capacity and stability of composite materials Decrease and other issues, to achieve the effect of large specific capacity, increased specific surface area, and increased reactive points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

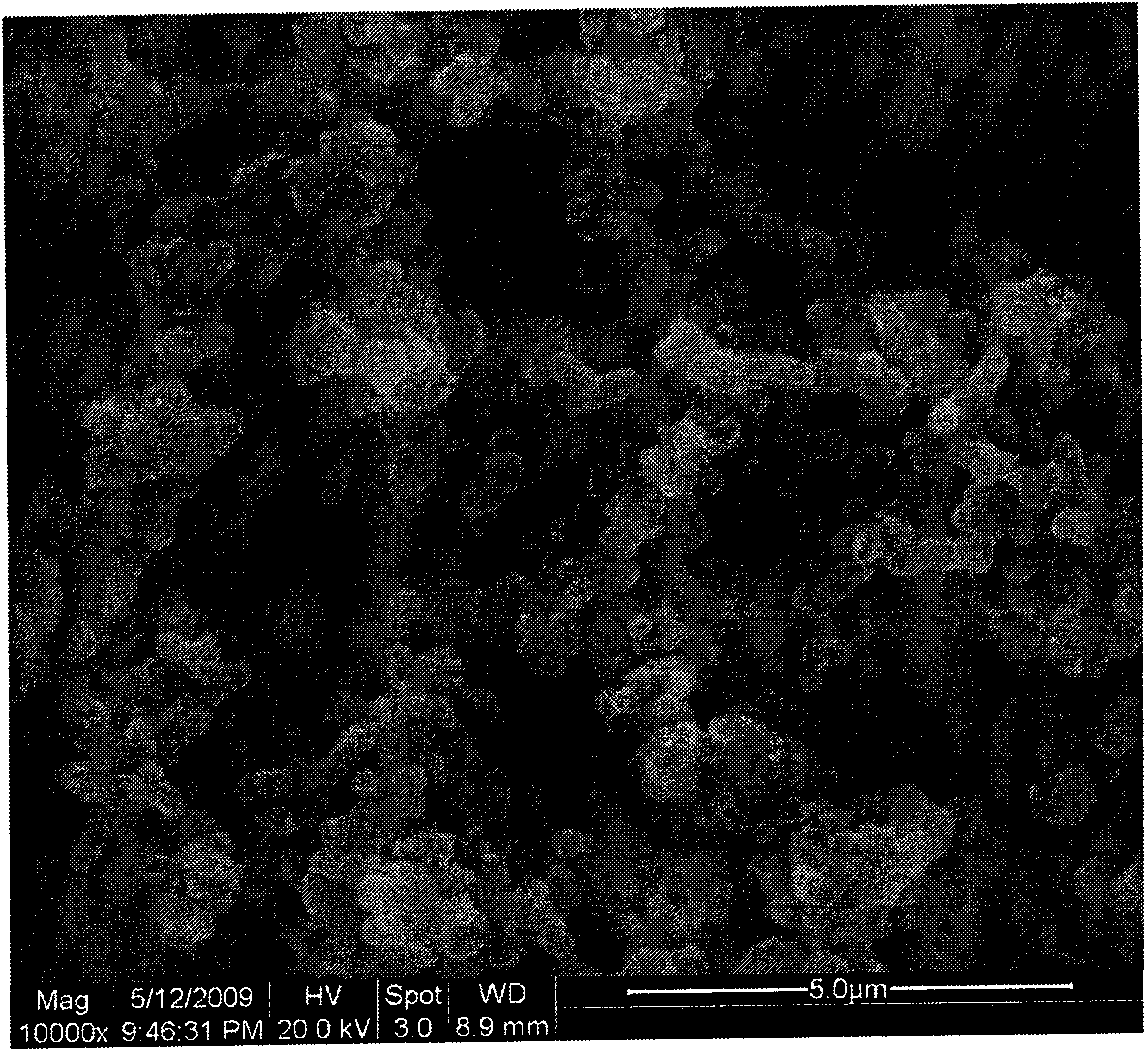

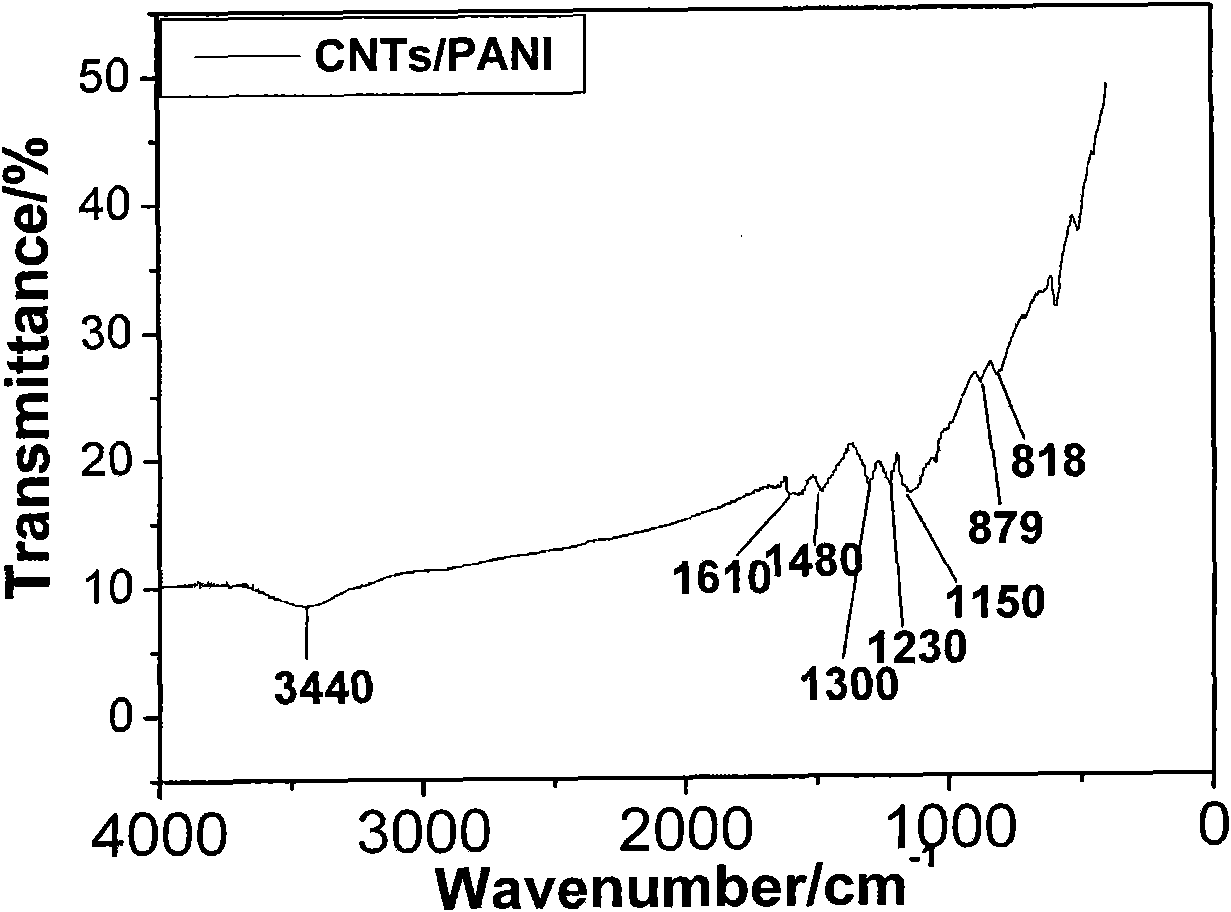

[0034] A kind of embodiment of the present invention is, a kind of preparation method of carbon nanotube / polyaniline network composite material, and its concrete practice is:

[0035] A. Carboxylated carbon nanotubes

[0036] Weigh 0.25g of carbon nanotubes and dissolve them in 50mL of concentrated nitric acid, ultrasonically disperse for 15min, then heat and reflux at 80°C for 8h, let stand and cool, wash with distilled water, filter with suction, and dry in vacuum at 60°C for 24h to obtain carboxylated carbon nanotubes ;

[0037] B. Carbonyl chloride nanotubes

[0038] Dissolve 0.2 g of carboxylated carbon nanotubes in step A in 60 mL of thionyl chloride, add 2 mL of N,N-dimethylformamide (DMF), and react at 65°C for 24 hours to obtain a mixed solution; after the mixed solution is cooled to room temperature , washed with tetrahydrofuran and dried to obtain acyl chloride carbon nanotubes;

[0039] C. Amidated carbon nanotubes

[0040] The acyl chloride carbon nanotubes in s...

Embodiment 2

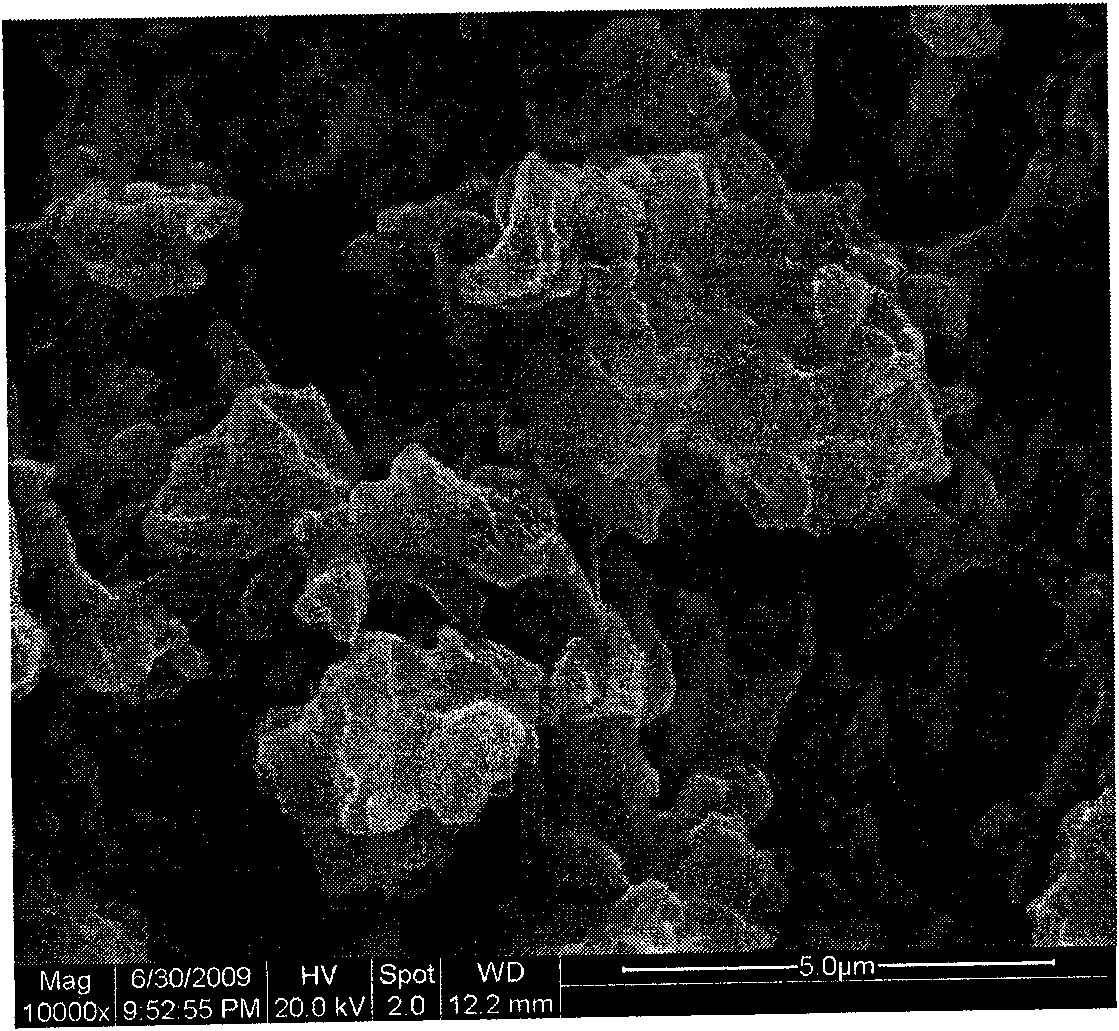

[0051] The method of this example is basically the same as that of Example 1, except that the reaction temperature and reaction time of step A carbon nanotube carboxylation are 25°C and 48h respectively; the reaction temperature of step B carbon nanotube acid chlorination and reaction time were 25°C and 48h, respectively; the reaction temperature and reaction time of step C carbon nanotube amidation were 40°C and 0.5h, respectively; the concentration of aniline in step D electrochemical deposition polymerization was 0.1mol L -1 At the same time, the method of applying voltage to the electrode during electrochemical deposition is a constant voltage method, and its voltage is constant at 1.2V; the working electrode is a nickel sheet; the CNTs / PANI mesh composite film electrodeposited on the nickel sheet is obtained, and the film is formed into a sheet shape, with a deposition thickness of about 1 cm.

Embodiment 3

[0053] The method of this example is basically the same as the production method of Example 1, the difference is only: the reaction temperature and reaction time of step A carboxylated carbon nanotubes are respectively 100 ℃ and 0.5h; The temperature and reaction time were 80°C and 0.5h, respectively; the reaction temperature and reaction time of the C-step amidation of carbon nanotubes were 20°C and 6h, respectively; the concentration of aniline in the D-step electrochemical deposition polymerization was 0.5mol L -1 , the method of applying voltage during electrochemical deposition is linear scanning method, and its voltage scanning range is -0.2~1.2V (scanning speed is 50mV s -1 ); the working electrode is metal aluminum; the electrolyte solution is a neutral electrolyte solution, and the prepared material is soaked in an acid solution before the capacity test. The electrodeposited CNTs / PANI mesh composite film on aluminum is obtained, and the film is fibrous, and the deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com