Hydrolysis process for preparing humic acid (HA) from corn straw

A humic acid and corn stalk technology, applied in organic fertilizers, organic chemistry and other directions, can solve the problems of high catalytic acid concentration, long heating time and long reaction period, and achieve the effects of high content, easy operation and strong biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

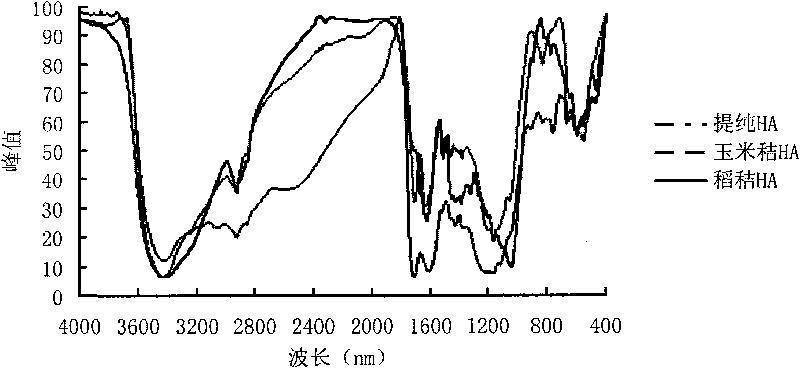

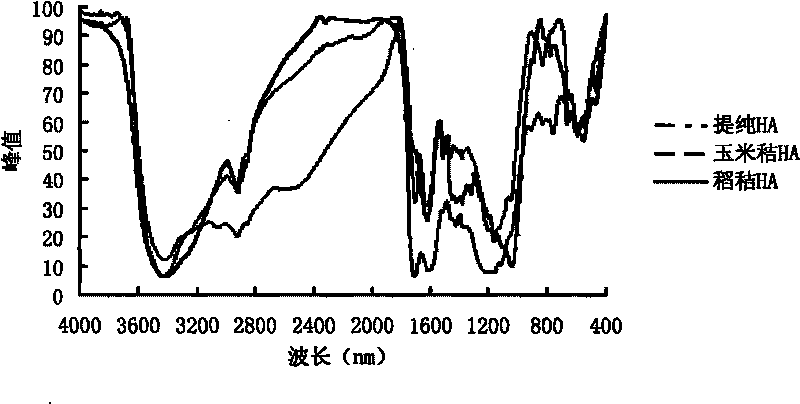

Image

Examples

Embodiment 1

[0017] 300 grams of air-dried corn stalks are crushed through a 20-mesh sieve, put into a high-temperature and high-pressure reactor, and a sulfuric acid solution with a mass percentage concentration of 0.1% is added according to the solid-to-liquid ratio of 1:0.8, and the stirrer speed is 300 rpm. React for 30 minutes, condense and cool down to 70°C, stirrer speed is 300rpm, react for 30 minutes, collect the residue in the kettle, dry and pulverize at 60°C, pass all through a 2.5 mm sieve, and use 1% of the mass percentage concentration at room temperature Sodium hydroxide solution is used as the extractant, the solid-to-liquid ratio is 1:12.5, shake and extract for 30 minutes, centrifuge at 2500rpm for 20 minutes, take the supernatant, adjust its pH value to 2 with concentrated hydrochloric acid for acidification, shake for 0.5 hours, filter Take the solid sample, then add 1mol / L sodium hydroxide solution according to the solid-liquid ratio of 1:10, shake for 30 minutes, let ...

Embodiment 2

[0019] Crush 300 grams of air-dried corn stalks through a 20-mesh sieve, put them into a high-temperature and high-pressure reaction kettle, add a sulfuric acid solution with a mass percentage of 0.05% according to the solid-to-liquid ratio of 1:10, and react at 220°C at a stirrer speed of 300 rpm For 30 minutes, condense and cool down to a temperature of 70°C, the speed of the agitator is 200rpm, react for 30 minutes, collect the residue in the kettle, dry and pulverize at 60°C, and pass through a 2.5mm sieve. The solution is the extractant, the solid-to-liquid ratio is 1:10, shake and extract for 40 minutes, centrifuge at 3500rpm for 30 minutes to get the supernatant, adjust its pH value to 2 with concentrated hydrochloric acid for acidification, shake for 0.5 hours, filter to get a solid sample, Then add 1mol / L sodium hydroxide solution according to the solid-liquid ratio of 1:10, shake for 30 minutes, let stand for 8-10 hours, centrifuge the extract at 3000rpm for 20 minute...

Embodiment 3

[0021]Crush 300 grams of air-dried corn stalks through a 20-mesh sieve, put them into a high-temperature and high-pressure reactor, add a sulfuric acid solution with a mass percentage of 0.1% according to the solid-to-liquid ratio of 1:12, and react at 220°C at a stirrer speed of 300 rpm For 20 minutes, condense and cool down to a temperature of 70°C, the speed of the agitator is 300rpm, react for 30 minutes, collect the residue in the kettle, dry and pulverize at 60°C, pass through a 2.5 mm sieve, and use 2% sodium hydroxide as a mass percentage at room temperature The solution is the extractant, the solid-to-liquid ratio is 1:12.5, shake and extract for 30 minutes, centrifuge at 3500rpm for 30 minutes to take the supernatant, adjust the pH value to 2 with concentrated hydrochloric acid for acidification, shake for 0.5 hours, filter to take the solid sample, Then add 1mol / L sodium hydroxide solution according to the solid-liquid ratio of 1:10, shake for 30 minutes, let stand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com