Application of r-polyglutamic acid or salt thereof in dairy product as addition agent

A technology of polyglutamic acid and dairy products, applied in dairy products, applications, milk preparations, etc., can solve problems such as high viscosity, reduced mineral utilization rate, barriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

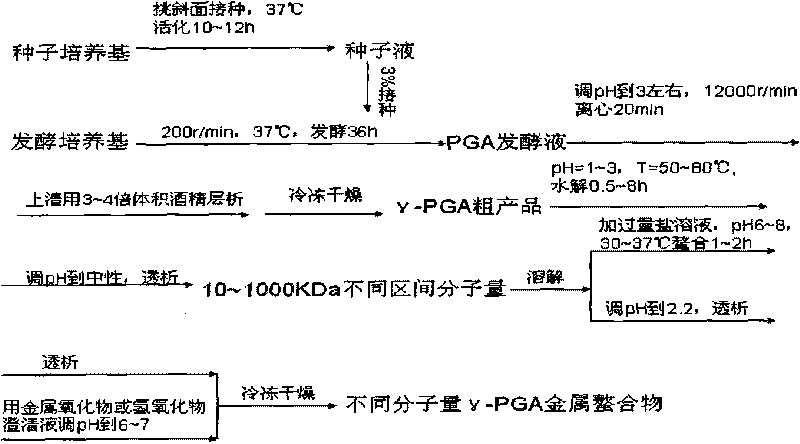

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Isolation and identification of poly-γ-glutamic acid producing strain Bacillus licheniformis WX-02

[0049] Weigh 1g of the soil sample from the high-salt environment of Yingcheng Salt Mine in Hubei Province into a sterile test tube, add 9 mL of sterile water, seal with a cotton stopper, shake for 2 minutes, then put it in a water bath, heat at 80°C for 10 minutes, and then stand for 30 minutes. After cooling, draw 0.1 mL of the supernatant, dilute 10-2, 10-3, respectively take 0.2 mL, spread on an LB plate, incubate at 37°C for 48 hours to observe the results, and select a single colony that is emulsion-like and drawable on the LB medium , Connected to the fresh liquid seed culture medium, cultured in a shaker at 37°C for 12 hours, inoculated into 250mL shake flasks containing 50mL sterile basic fermentation medium at a rate of 2% at 37°C, 190r / min, shaking The fermentation was ended after 36 hours of cultivation. The fermentation products were sampled and cen...

Embodiment 2

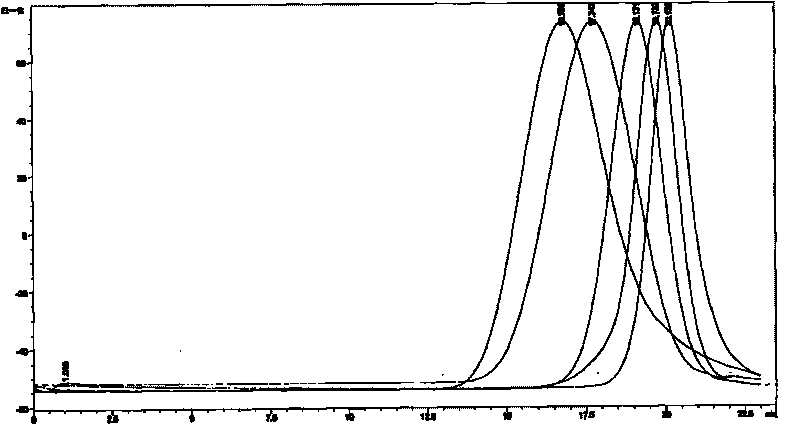

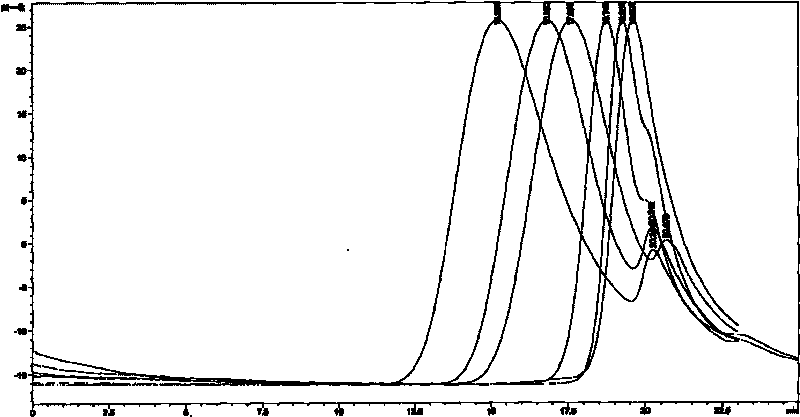

[0050] Example 2: HPLC analysis method of poly-γ-glutamic acid

[0051] The quantitative analysis of poly-γ-glutamic acid was completed by HPLC, column Agilent 1100, mobile phase 100mM KH 2 PO 4 Add 5.0% methanol (adjust the pH value to 2.5 with phosphoric acid), filter, ultrasonically degas, ultraviolet detection wavelength is 210nm, flow rate is 1ml / min, and glutamic acid is used as a quantitative standard. The molecular weight is analyzed by the American Waters liquid chromatograph, equipped with Japanese TSK Gel G6000 PWXL (7.8mm×300mm) gel permeation chromatography column and Waters 2487 ultraviolet detector. The mobile phase is 25mmol / L Na2SO4: acetonitrile=8:1 (v / v), the flow rate is 0.5ml / min, the detection wavelength is 210nm, and the purified γ-PGA is used as a quantitative standard.

[0052] The production determination steps of poly-γ-glutamic acid are as follows:

[0053] Take 5 ml of fermentation centrifugal supernatant, add 3 times the volume of alcohol to precipitate...

Embodiment 3

[0056] Example 3: Liquid batch fermentation production of poly-γ-glutamic acid

[0057] 1. Use the frozen-preserved strain Bacillus licheniformis WX-02 as the original strain

[0058] 2. Inclined bacteria

[0059] Inoculate the frozen-preserved strain Bacillus licheniformis WX-02 into the LB solid slope (Ingredients: peptone 10g / L, yeast extract 5g / L, NaCl 10g / L, agar 15g / L, pre-sterilization medium The pH is 7.0), cultivated at 30°C-37°C for 24-36 hours.

[0060] 3. Seed liquid culture

[0061] Transfer the seeds activated by the LB solid slope to the liquid seed culture medium containing peptone 10g / L, yeast extract 5g / L, NaCl 10g / L, pH 7.0, 30℃-37℃, 200rpm Cultivate for 14-16 hours to mid-log growth period;

[0062] 4. Fermentation tank culture

[0063] Configure the fermentation medium according to the amount added per 1 liter of medium: 40-100 grams of glutamic acid; 50-100 grams of glucose; 10-30 grams of citric acid; 3-20 grams of ammonium chloride; K 2 HPO 4 ·3H 2 O 0.1-2 grams;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com