Preparation method of In-situ polymerization microcapsule

An in-situ polymerization and microencapsulation technology, applied in the directions of microcapsule preparation, microsphere preparation, etc., can solve the problems of difficulty in realization and limit the scope of application of traditional in-situ polymerization and microencapsulation technology, so as to improve efficiency and process stability. Excellent, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 : Preparation of polymethyl methacrylate coated paraffin microcapsules

[0025] The preparation process is as follows:

[0026] Take 10.0g of paraffin wax, 5.0g of n-butyl stearate and 5.0g of methyl methacrylate, add 3.0g of surfactant, heat in a water bath at 40°C and stir at 500r / min to make an oil phase; among them, The surfactant is a compound emulsifier composed of sorbitan oleate 80 (Span80) and polyoxyethylene sorbitan monooleate 80 (Tween80) in a mass ratio of 0.4:0.6.

[0027] Slowly add the above oil phase dropwise to 100.0g of the water phase under stirring at 40°C, and stir and emulsify for 30 minutes to obtain a stable emulsion;

[0028] Get ammonium persulfate 0.075g and sodium bisulfite 0.075g, add distilled water respectively and be made into each 5g initiator aqueous solution (totally 10g). Take out 1 / 3 of each initiator aqueous solution, slowly drop it into the above emulsion, stir at 500r / min and raise the temperature to 55°C to initiat...

Embodiment 2

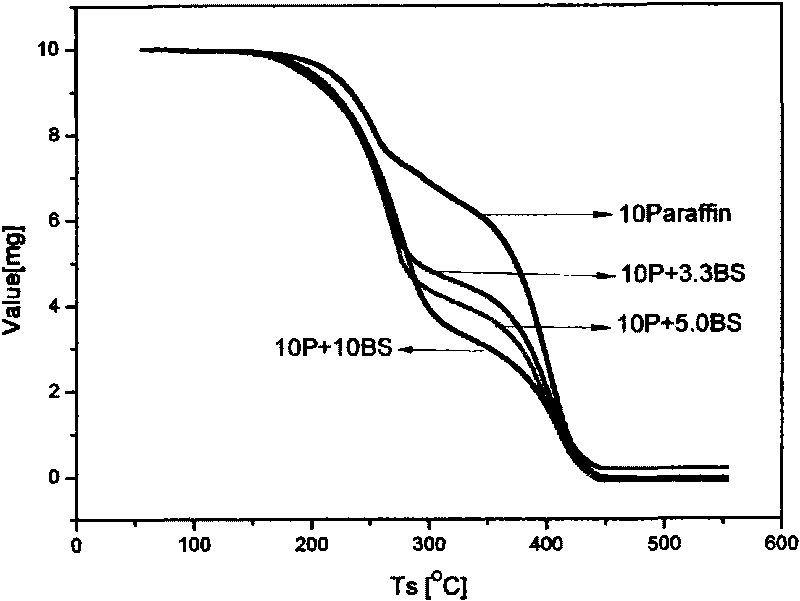

[0031] Example 2 : Preparation and comparative analysis of a series of polymethyl methacrylate-coated paraffin wax microcapsules with different additions of n-butyl stearate

[0032] In embodiment 2, keep total core material (i.e. paraffin and n-butyl stearate, n-butyl stearate is also regarded as a part of core material) and organic macromolecular monomer (i.e. methyl methacrylate) The mass ratio is constant (i.e. the same as the corresponding mass ratio of 3: 1 in Example 1), the addition of n-butyl stearate is adjusted, and the preparation process of Example 1 is still adopted to prepare n-butyl stearate respectively A series of microcapsules added in different amounts, resulting in a linear change in the coverage of the core material.

[0033] Figure 3a , b is the thermal weight loss relationship curve and thermal weight loss percentage of methyl methacrylate-coated paraffin wax in-situ polymerized microcapsules corresponding to different n-butyl stearate additions. I...

Embodiment 3

[0039] Example 3 : Preparation of polystyrene-coated microcapsules of essential oils

[0040] The preparation process is as follows:

[0041] Example 3 uses a mixture of essential oil and petroleum ether as the core material, and diethyl phthalate as the solubilizing material. Firstly 3.0g essential oil is dissolved in 7.0g sherwood oil to make core material, then this core material, 5.0g diethyl phthalate, 5.0g styrene and 3.0g surfactant, at room temperature, 500r / Mix under stirring conditions for 1 min to make an oil phase; wherein, the surfactant is selected from sorbitan oleate 80 (Span80) and polyoxyethylene sorbitan monooleate 80 (Tween80) in a mass ratio of 0.4:0.6 Composed of compound emulsifiers.

[0042] Slowly add the above oil phase dropwise into 100.0 g of the water phase under stirring, and stir and emulsify for 30 minutes to obtain a stable emulsion;

[0043] Take 0.075 g of ammonium persulfate and 0.075 g of sodium bisulfite, and add distilled water resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com