Spot coating type high-temperature tin alloy soldering paste and preparation method thereof

A tin alloy and solder paste technology, which is applied in the field of high-temperature tin alloy solder paste and its preparation, can solve the problems of separation of tin powder and solder paste, high soldering temperature, blackening of residues, etc., to reduce metal surface tension and improve Expansion rate, corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

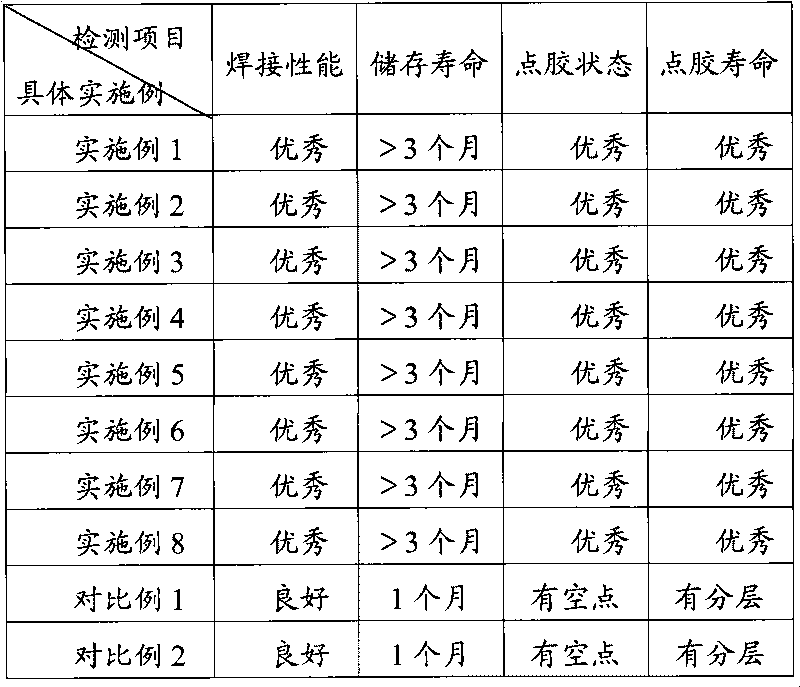

Examples

Embodiment 1

[0033] Flux raw materials: polymerized rosin 25g, hydrogenated rosin 20g, modified hydrogenated castor oil 2g, hydrogenated castor oil wax 4g, glutaric acid 2g, cyclohexylamine hydrochloride 1g, hydroquinone 1g, stearic acid dispersant 1g And terpineol 30g, diethylene glycol monobutyl ether 14g.

[0034] Preparation method: Mix 25g of polymerized rosin, 20g of hydrogenated rosin, 30g of terpineol, and 14g of diethylene glycol monobutyl ether, stir and heat to 145°C for dissolution, then add 1g of hydroquinone and 2g of modified hydrogenated castor oil , 4g hydrogenated castor oil wax and 1g ethylene bis stearic acid amide, after completely dissolving, add 2g glutaric acid, 1g cyclohexylamine hydrochloride, cool after the above materials are completely dissolved, and get flux when cooled to room temperature 12g of flux and 88g of Sn5 / Pb92.5 / Ag2.5 solder alloy powder were mixed and stirred in a vacuum disperser, and the solder paste of the alloy was obtained after stirring evenl...

Embodiment 2

[0036] Flux raw materials: polymerized rosin 30g, hydrogenated rosin 15g, modified hydrogenated castor oil 3g, hydrogenated castor oil wax 3g, succinic anhydride 2g, cyclohexylamine hydrochloride 1g, hydroquinone 1.5g, stearic acid dispersant 2g and diethylene glycol monohexyl ether 20, diglycidyl ether 22.5g.

[0037] Preparation method: Mix 30g of polymerized rosin, 15g of hydrogenated rosin, 20g of diethylene glycol monohexyl ether, and 22.5g of diglycidyl ether, stir and heat to 150°C for dissolution, then add 1.5g of hydroquinone, 3g of modified Hydrogenated castor oil, 3g hydrogenated castor oil wax and 1.5g ethylene bisstearic acid amide, after dissolving completely, add 2g succinic anhydride, 1g cyclohexylamine hydrochloride, cool after the above materials are completely dissolved, and cool to room temperature When the flux is obtained, take 11g of flux and 89g of Sn5 / Pb92.5 / Ag2.5 solder alloy powder and mix and stir in a vacuum disperser, and after stirring evenly, a ...

Embodiment 3

[0039] Flux raw materials: polymerized rosin 30g, hydrogenated rosin 15g, modified hydrogenated castor oil 4g, hydrogenated castor oil wax 2g, glutaric acid 1g, cyclohexylamine hydrochloride 2g, hydroquinone 2g, stearic acid dispersant 2g and 42g terpineol.

[0040] Preparation method: Mix 30g of polymerized rosin, 15g of hydrogenated rosin and 42g of terpineol, stir and heat to 150°C for dissolution, then add 2g of hydroquinone, 4g of modified hydrogenated castor oil, 2g of hydrogenated castor oil wax and 2g of ethyl alcohol Bis stearic acid amide, add 1g of glutaric acid after complete dissolution, 2g of cyclohexylamine hydrochloride, cool after the above materials are completely dissolved, get flux when cooled to room temperature, take flux 13g and Sn5 / Pb92 .5 / Ag2.5 solder alloy powder 87g was mixed and stirred in a vacuum disperser, and the solder paste of the alloy was obtained after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com