Method for preparing abrasion-resistant ceramic lining plate by using active soldering method

A wear-resistant ceramic and active brazing technology is applied in the field of preparing wear-resistant ceramic lining plates, which can solve the problems of easy aging of rubber materials, easy falling off of ceramics, low bonding strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

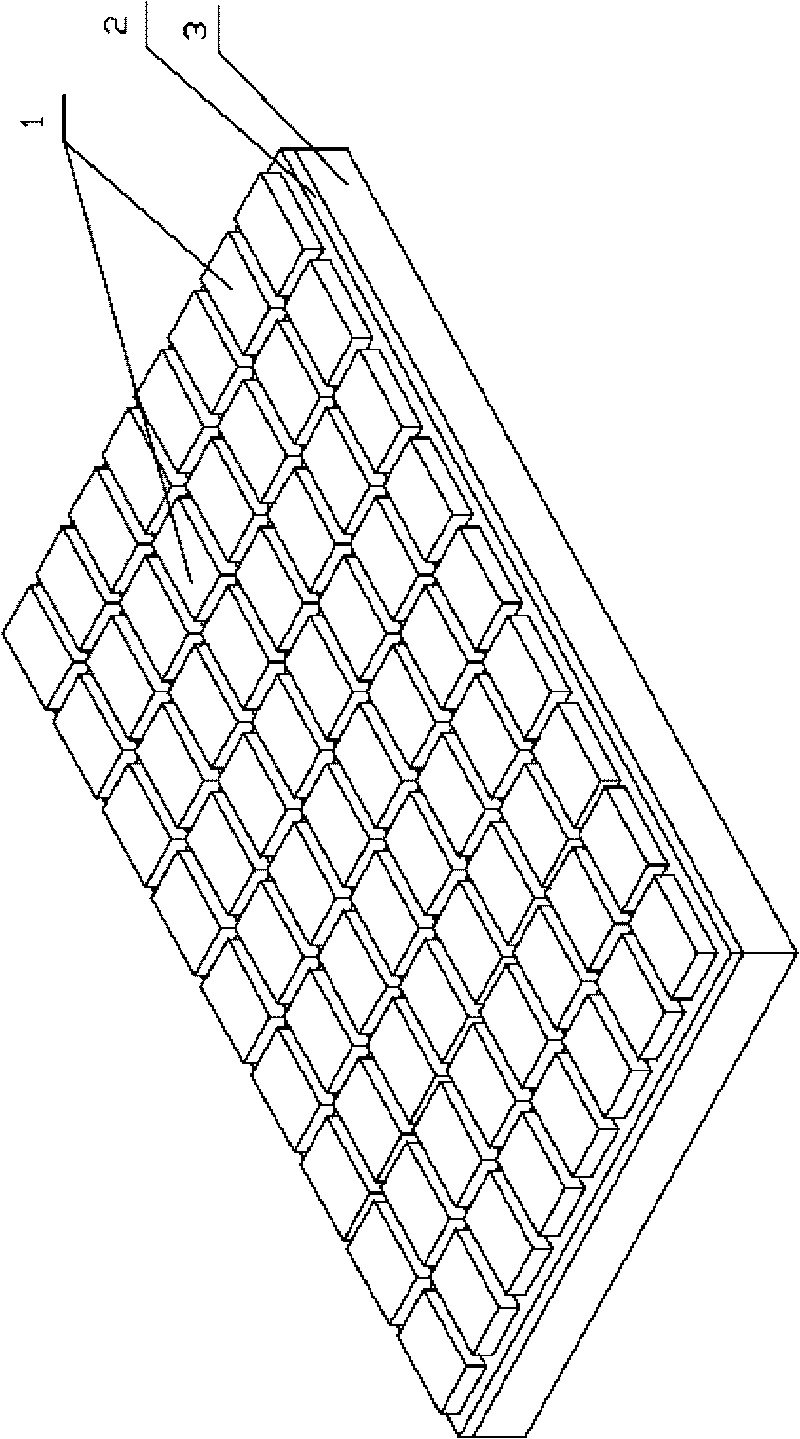

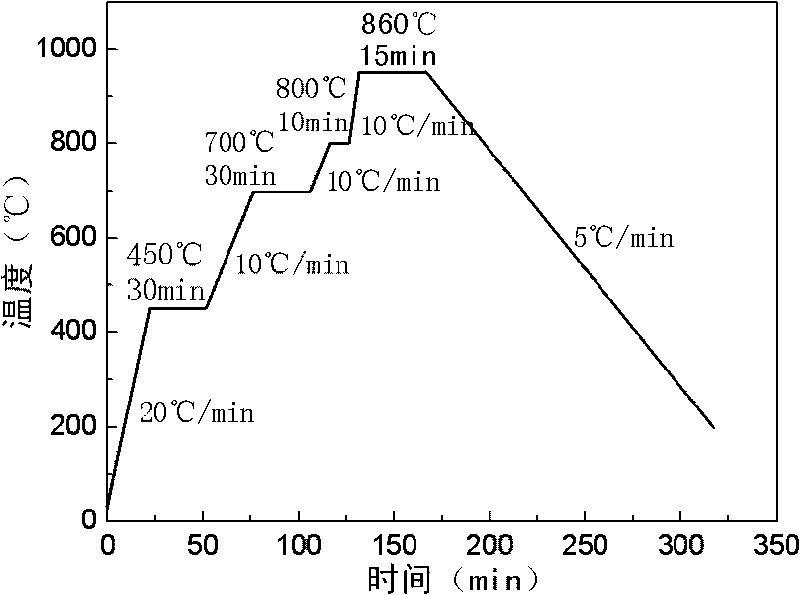

[0018] Specific embodiment one: the method for preparing the wear-resistant ceramic liner with the active brazing method in this embodiment is realized by the following method: one, by mass fraction, 60%~80% Ag powder, 18%~35% Cu Powder and 1%~5% TiH 2 Put the powder into a stainless steel tank after mixing, then add acetone to make the acetone 1-5cm higher than the mixed powder, then fill the stainless steel tank with inert gas, seal the stainless steel tank, and then ball mill for 25-30 hours, then mix the powder after ball milling Powder and binder are mixed to obtain active metal paste solder, wherein the mass ratio of ball to material is 20:1, the mass ratio of mixed powder to binder is 20:1, and the mass fraction of binder is from 0.8% to 1.2 % glycerol, 95% to 97% distilled water and 2% to 4% hydroxyethyl cellulose; 2. Clean the surface of the ceramic block and the low-alloy high-strength structural steel plate respectively, then dry it naturally, and then put the ceram...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 70% Ag powder, 27% Cu powder and 3% TiH 2 The powder is mixed and placed in a stainless steel tank. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the inert gas in step 1 is argon or helium. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com