Method for synthesizing 2-ethoxy n-octyl thioether through three phase transfer catalysis without solvent

A technology of n-octyl sulfide and phase transfer catalysis, which is applied to the synthesis of asymmetric thioether, 2-hydroxyethyl n-octyl sulfide, and the synthesis of organic thioether, can solve the problem of low yield, Solve the problems of high risk of sodium metal and many by-products, and achieve the effect of simple reaction system, simple separation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

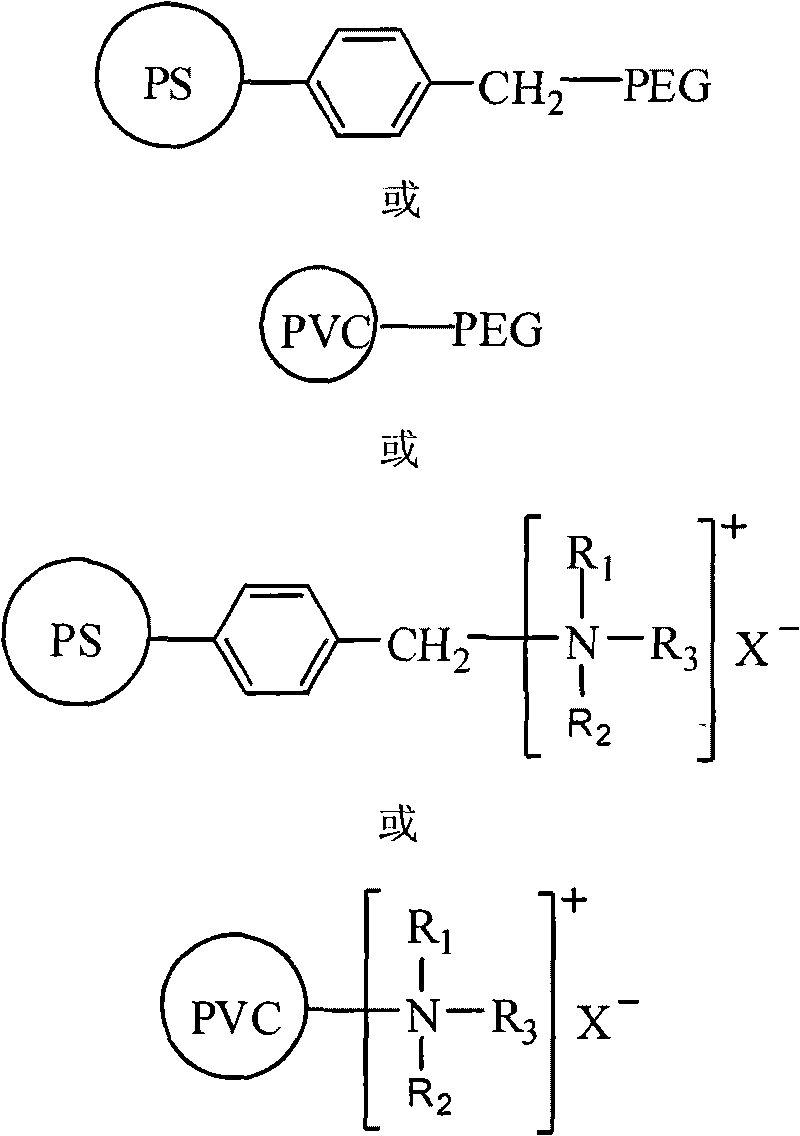

[0054] Add sodium carbonate 4.2g (0.04mol) and deionized water in reaction system, stir and dissolve, pass into nitrogen protection, add n-octyl mercaptan 0.1mol and polystyrene (PS) graft PEG-200 catalyst 1.6g, then Add 0.1 mol of 2-chloroethanol dropwise, without organic solvents, under normal pressure, 40°C, react for 6 hours, filter out the catalyst after the reaction is over, let the filtrate stand for stratification, separate the oil phase and water phase, and perform gas chromatography on the oil phase Analysis showed that the yield of detoxol was 88.1%.

[0055] Under the above reaction conditions, the catalyst polystyrene (PS) grafted with PEG-200 was reused 6 times according to the above scheme, and the average yield of repellent alcohol was 87.7%.

Embodiment 2

[0057] Add salt of wormwood 8.3g (0.06mol) and deionized water in reaction system, stir and dissolve, pass into nitrogen protection, add n-octyl mercaptan 0.1mol and polyvinyl chloride (PVC) graft PEG-200 catalyst 1.8g, then Add 0.15 mol of 2-chloroethanol dropwise, without organic solvent, under normal pressure, 45°C, react for 7 hours, filter out the catalyst after the reaction, leave the filtrate to separate layers, separate the oil phase and water phase, and perform gas chromatography on the oil phase Analysis showed that the yield of detoxol was 84.8%.

[0058] Under the above reaction conditions, the catalyst polyvinyl chloride (PVC) grafted with PEG-200 was reused 5 times according to the above scheme, and the average yield of repellent alcohol was 83.9%.

Embodiment 3

[0060] The experimental procedure is the same as above, and the reaction conditions are as follows: n-octyl mercaptan 0.1mol, 2-chloroethanol 0.12mol, polystyrene (PS) grafted PEG-400 2.0g, sodium hydroxide 4.8g (0.12mol), no organic solvent, usually Press down, react at 70°C for 10 hours, filter out polystyrene (PS) grafted PEG-400, separate the oil phase, and perform gas chromatography analysis. The yield of detoxol is 96.8%.

[0061] Under the above reaction conditions, the catalyst polystyrene (PS) grafted with PEG-400 was reused 6 times according to the above scheme, and the average yield of repellent alcohol was 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com