Preparation method of lithium ion battery negative electrode material charcoal microballoon

A technology of negative electrode materials and carbon microspheres, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large irreversible capacity, complex process, high cost, etc., and achieve excellent electrochemical performance, low preparation cost, and high compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

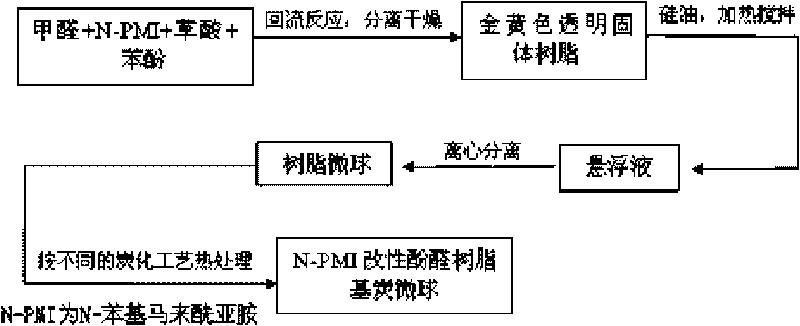

[0059] 1. Synthesis of N-phenylmaleimide modified phenolic resin

[0060]Add phenol, formaldehyde, N-phenylmaleimide and catalyst in a certain ratio (10:74:14:2, weight ratio) into a three-necked flask, and raise it to a certain reaction temperature (70-80°C) to start Phenol is added dropwise, and after a certain time (10-12 hours) of reflux reaction, water and formaldehyde are distilled off under reduced pressure to end the reaction. The product is dissolved in acetone (the mass ratio of resin to acetone is 1:5), and the Is Jia Shi empty? 0%) mixed solution (resin and mixed solution mass ratio is 1: 10) in the separatory funnel, raw material monomers such as unreacted N-phenylmaleimide are dissolved in acetone and are in the upper layer of mixed solution, N-phenyl The base maleimide-modified phenolic resin product precipitated in the lower layer of the mixed solution, and this process was repeated twice continuously. The precipitated product was separated and dried in a v...

Embodiment 2

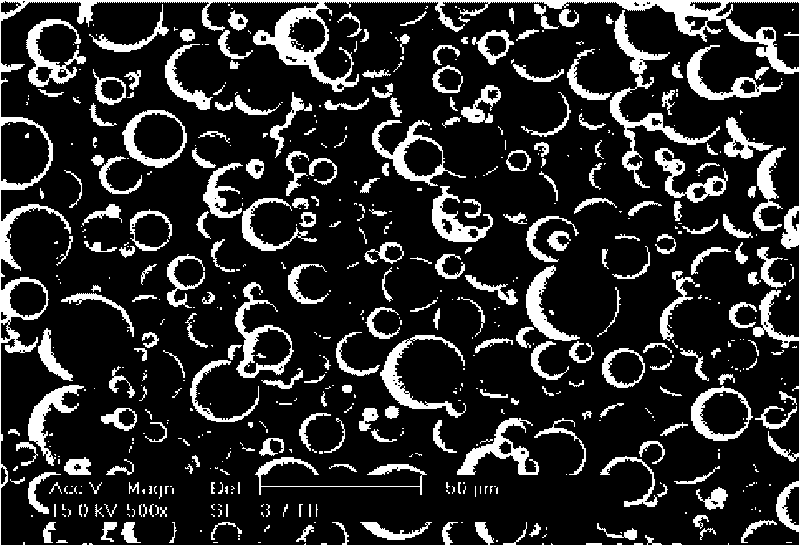

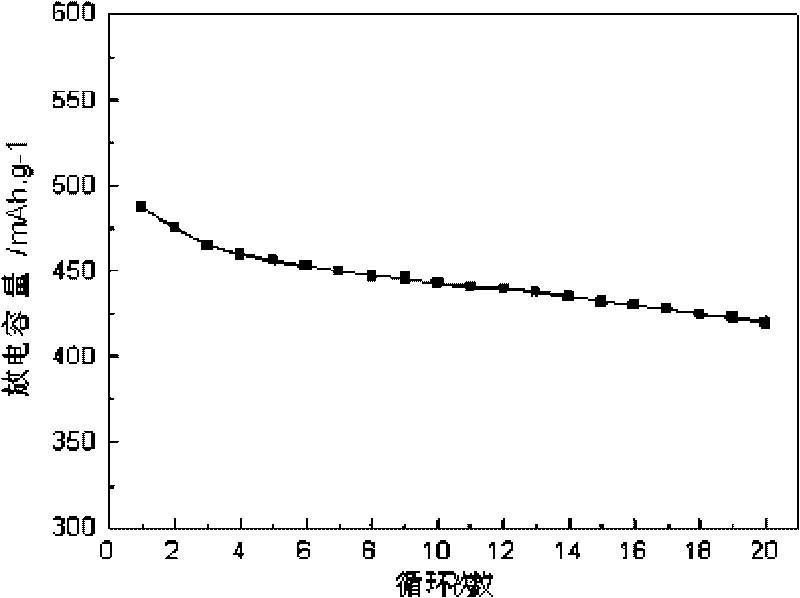

[0064] Synthesize N-phenylmaleimide modified phenolic resin according to step (1) of Example 1. Put the prepared resin into a mortar for grinding, and then sieve through a 200-mesh sieve after grinding. Get a 1000ml three-necked flask, measure 500ml of silicone oil and pour it into it, then put 50g of resin powder, under the protection of nitrogen, put the three-necked flask into the electric heating mantle, stir (stirring speed is 1000rpm), and at 160 ℃ insulation 2h. Using tetrahydrofuran as a solvent, the silicone oil on the surface of the resin microspheres was removed by centrifugation, and then the microsphere samples were vacuum-dried at 100° C. for 6 hours to obtain a resin microsphere sample. Put the above resin microspheres into a high-temperature tube furnace, and pass through Ar 2 , the temperature was raised to 900°C at 5°C / min, and then kept for 2h, and cooled to room temperature in the furnace to obtain carbon microspheres.

Embodiment 3

[0066] Synthesize N-phenylmaleimide modified phenolic resin according to step (1) of Example 1. Put the prepared resin into a mortar for grinding, and then sieve through a 200-mesh sieve after grinding. Take a 1000ml three-neck flask, measure 500ml of silicone oil into it, and then put 80g of resin powder, under the protection of nitrogen, put the three-necked flask into the electric heating mantle, stir, and keep it at a certain temperature for 4 hours at 160°C . Using tetrahydrofuran as a solvent, the silicone oil on the surface of the resin microspheres was removed by centrifugation, and then the microsphere samples were vacuum-dried at 100° C. for 8 hours to obtain a resin microsphere sample. Put the resin microspheres into a high-temperature tube furnace and pass through Ar 2 , the temperature was raised to 1050°C at 10°C / min, and then kept for 1h, and cooled to room temperature in the furnace to obtain carbon microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com