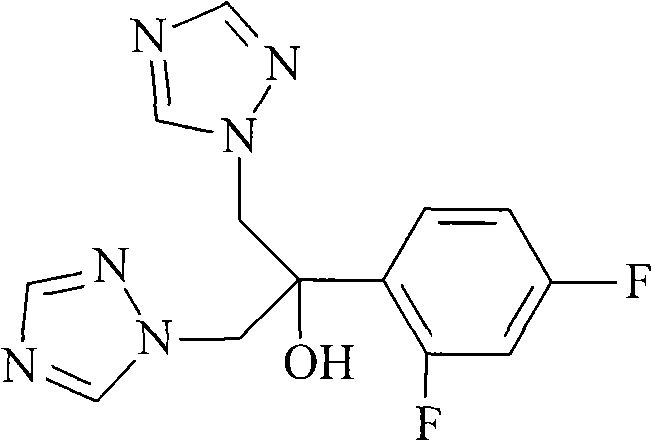

Solid preparation of fluconazole liposome and new application thereof

A technology of fluconazole lipid and solid preparation, applied in the field of liposome preparation, can solve the problems of low dissolution rate, poor stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

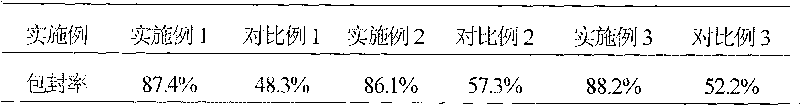

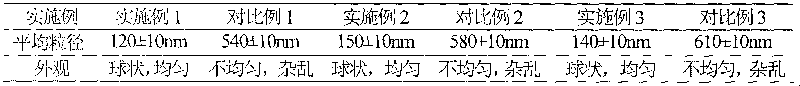

Embodiment 1

[0072] The preparation of embodiment 1 fluconazole liposome

[0073] prescription:

[0074] Component Dosage

[0075] Fluconazole 25g

[0076] Soy Lecithin 55g

[0077] Cholesterol 32.5g

[0078] Ascorbyl Palmitate 2.5g

[0079] Preparation Process

[0080] (1) 25g fluconazole, 55g soybean lecithin, 32.5g cholesterol and 2.5g ascorbyl palmitate are dissolved in the mixed solvent of methanol, Virahol and acetone with a volume ratio of 2:1:2 in 600ml, mix homogeneously, Remove the mixed solvent under reduced pressure on a rotary thin film evaporator to obtain a phospholipid film;

[0081] (2) Add 450ml of citric acid-sodium citrate buffer solution with a pH value of 6.5, shake and stir for 20 minutes at a speed of 600r / min to completely hydrate the phospholipid membrane, and emulsify it at a high speed using a tissue masher for 20 minutes minutes, keep warm at 60°C, rotate at 12000r / min, and then filter with a 0.45 μm microporous membrane to obtain a liposome suspension; ...

Embodiment 2

[0083] The preparation of embodiment 2 fluconazole liposomes

[0084] prescription:

[0085] Component Dosage

[0086] Fluconazole 50g

[0087] Soy Lecithin 210g

[0088] Cholesterol 150g

[0089] Ascorbyl Palmitate 22.5g

[0090] Preparation Process

[0091] (1) 50g fluconazole, 210g soybean lecithin, 150g cholesterol and 22.5g ascorbyl palmitate are dissolved in the mixed solvent of ethanol, isopropanol and methanol in a volume ratio of 1:1:2 in 3400ml, mix well, and The mixed solvent was removed under reduced pressure on a rotary thin film evaporator to obtain a phospholipid film;

[0092] (2) Add 2000ml of phosphoric acid-sodium hydrogen phosphate buffer solution with a pH value of 5.5, shake, stir for 40 minutes, and rotate at a speed of 200r / min to completely hydrate the phospholipid film, and use a tissue masher for high-speed homogeneous emulsification for 10 minutes, Insulate at 50°C, rotate at 15000r / min, and then filter with a 0.45μm microporous membrane to o...

Embodiment 3

[0094] The preparation of embodiment 3 fluconazole liposomes

[0095] prescription:

[0096] Component Dosage

[0097] Fluconazole 100g

[0098] Soy Lecithin 600g

[0099] Cholesterol 450g

[0100] Ascorbyl Palmitate 80g

[0101] Preparation Process

[0102] (1) 100g fluconazole, 600g soybean lecithin, 450g cholesterol and 80g ascorbyl palmitate are dissolved in the mixed solvent of tert-butanol, acetone and methanol in a volume ratio of 3:2:2 in 7500ml, mix well, and The mixed solvent was removed under reduced pressure on a rotary thin film evaporator to obtain a phospholipid film;

[0103] (2) Add 3500ml of citric acid-sodium citrate buffer solution with a pH value of 7.5, shake, stir for 30 minutes, and rotate at 400r / min to completely hydrate the phospholipid film, and use a tissue masher for high-speed homogeneous emulsification for 15 minutes Minutes, keep warm at 60°C, rotate at 15000r / min, and then filter with a 0.45 μm microporous membrane to obtain a liposome ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com