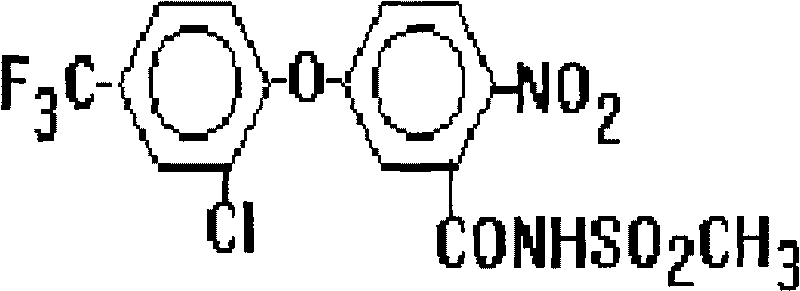

Fomesafen soluble solid medicament form

A technology of fomesafen and solid dosage forms, applied in the field of soluble solid dosage forms, can solve problems such as increased production and transportation costs, waste of resources, environmental pollution, etc., achieve good economic benefits and environmental protection values, and reduce production and storage and transportation costs , The effect of reducing the amount of packaging materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Formula: 95% fomesafen powder 20%

[0026] Sodium Lignin Naphthalene Sulfonate 3%

[0027] Polyoxyethylene triglyceride 6%

[0028] Silica 10%

[0029] Sodium sulfate top up 100%

[0030] Production Method:

[0031] First, the original fomesafen powder and sodium hydroxide that has been crushed to 98% and over 100 mesh, additives and fillers are added to the mixer according to the formula (if the additives are in liquid state, they can be adsorbed with white carbon black first), and mixed evenly It is made into powder or granule, packaged, put into water, stirred and dissolved before use.

example 2

[0033] Formula: 95% fomesafen powder 80%

[0034] Sodium Hydroxide 10%

[0035] Polymer Carboxylate 5%

[0036] Silica Top Up 100%

[0037] First, the original fomesafen powder and sodium hydroxide that has been crushed to 98% and over 100 mesh, additives and fillers are added to the mixer according to the formula (if the additives are in liquid state, they can be adsorbed with white carbon black first), and mixed evenly It is made into powder or granule, packaged, put into water, stirred and dissolved before use.

example 3

[0039] Formula: 95% fomesafen powder 50%

[0040] Sodium Hydroxide 6%

[0041] Naphthalene sulfonate formaldehyde condensate 5%

[0042] Polyethylene oxide propylene oxide ether 15%

[0043] Silica 10%

[0044] Sodium sulfate top up 100%

[0045] First, the original fomesafen powder and sodium hydroxide that has been crushed to 98% and over 100 mesh, additives and fillers are added to the mixer according to the formula (if the additives are in liquid state, they can be adsorbed with white carbon black first), and mixed evenly It is made into powder or granule, packaged, put into water, stirred and dissolved before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com