A kind of production equipment and production method of high-purity nano metal superfine powder

A nano-metal and production equipment technology, which is applied in the field of high-purity nano-metal superfine powder production equipment, can solve problems such as high cost, high production cost, and raw material restrictions, and achieve the effects of wide application range, low cost, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

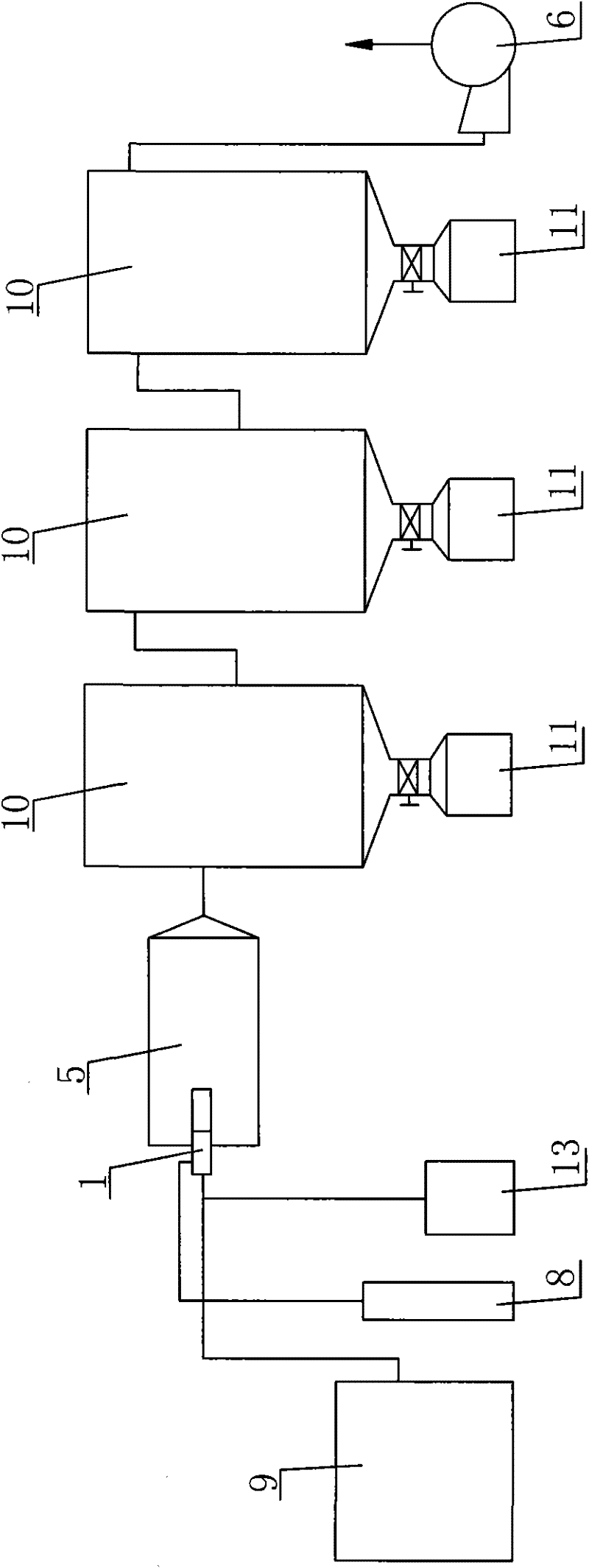

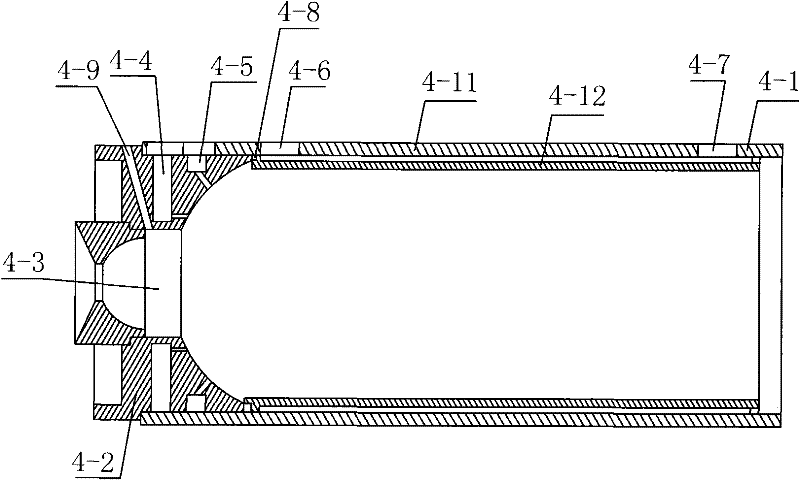

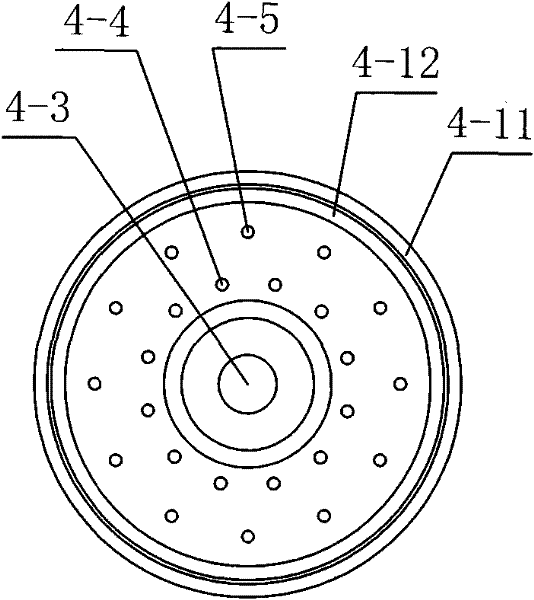

[0059] In this embodiment, the raw material to be processed is molybdenum wire. Therefore, in the present embodiment, the high-purity nano-metal ultrafine powder production equipment used includes the raw material delivery and pretreatment device one, the supersonic nozzle 3 arranged inside the raw material delivery and pretreatment device one, the feed inlet and the raw material The high-temperature liquid mist combustion fast reducer 4 connected to the discharge port of the conveying and pretreatment device 1, the inert gas rapid condensation device 5 connected to the discharge port of the high-temperature liquid mist combustion fast reducer 4, and the inert gas The multi-stage metal ultrafine powder classification device connected to the discharge port of the gas rapid condensation device 5 and a plurality of devices are respectively arranged below the multi-stage metal ultrafine powder classification device and are connected to the discharge port below the multi-stage metal...

Embodiment 2

[0075] In this embodiment, the raw material to be processed is selenium (Se) powder with an average particle diameter of 60 μm, so it is different from the high-purity nano metal ultrafine powder production equipment in Example 1: the raw material delivery and pretreatment device 1 used It is the raw material conveying and pretreatment device 2 and uses hydrocarbon fuel as the gas source (that is, under the action of hydrocarbon fuel) to carry out powder feeding. The powder feeding device is powder feeder 1 and the powder feeder 1 is equipped with electronic lighter. In actual use, the ignited selenium powder can also be sent to the high-temperature liquid mist combustion fast reducer 4 by using the powder feeding inclined plate as a powder feeding device. The front part of the high-temperature liquid mist combustion fast reducer 4 is provided with a powder feeding channel 4-9 connected to the discharge port of the powder feeder 1 .

[0076] In this embodiment, the difference...

Embodiment 3

[0078] In this embodiment, the raw materials to be processed are copper (Cu) wire with a diameter of 2mm and indium (In) powder, gallium (Ga) powder and selenium (Se) powder with an average particle size of 60 μm, and the atomic The molar ratio is 1:0.7-1:0.1-0.3:2, and the molar content of Se can be adjusted within the range of 1.3-2.5 according to specific needs during actual processing and preparation. Therefore, in this embodiment, the difference from the high-purity nano metal superfine powder production equipment in embodiment 1 is that the raw material conveying and pretreatment device 1 used is to convey and pretreat the metal wire and metal powder that are input at the same time Raw material conveying and pretreatment device III. The raw material conveying and pretreatment device three includes an arc torch with a wire input device capable of performing arc melting on simultaneously input metal wire and metal powder, and a powder feeding device is provided at the feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com