Method for preparing silicon nanowire array membrane electrode

A silicon nanowire array, silicon nanowire technology, applied in electrode manufacturing, battery electrodes, electrode carriers/current collectors, etc., can solve the problem that the contribution of silicon substrate cannot be excluded, and achieve improved electron transport, good performance, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The steps of this embodiment are as follows:

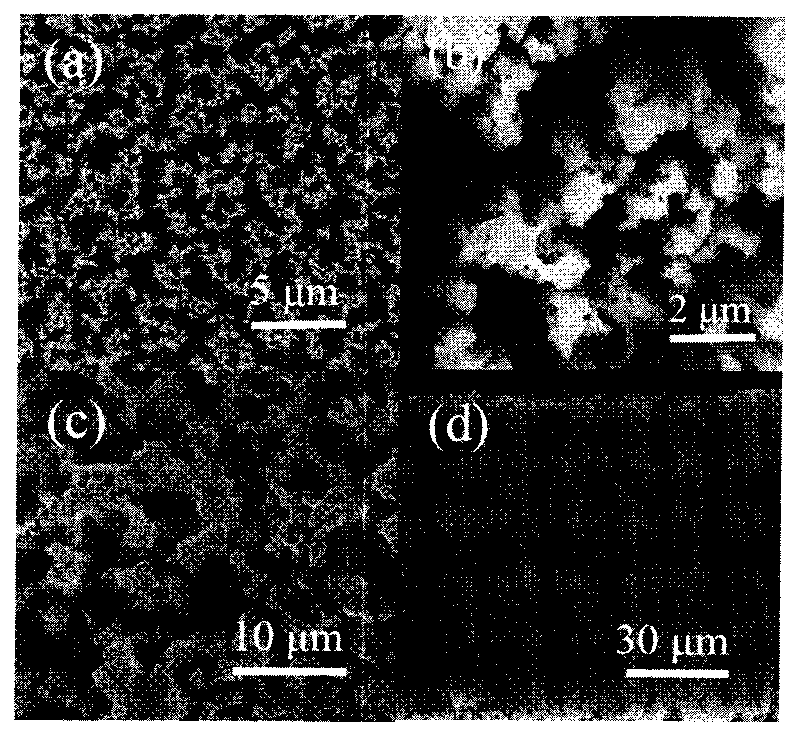

[0021] (1) Put the monocrystalline silicon wafer into the aqueous solution of hydrofluoric acid and silver nitrate for 60 seconds, the volume ratio of each component in the solution is: HNO 3 :HF:H 2 O=1:4:15, plate a layer of silver nanoparticle film with the method of electroless deposition;

[0022] (2) put the monocrystalline silicon chip that the surface is coated with silver nanoparticle film into the aqueous solution of hydrofluoric acid and hydrogen peroxide and corrode, the volume ratio of each component in the solution is: H 2 o 2 :HF:H 2 O=1:4:15, the corrosion temperature is 50°C, and the corrosion time is 90 minutes;

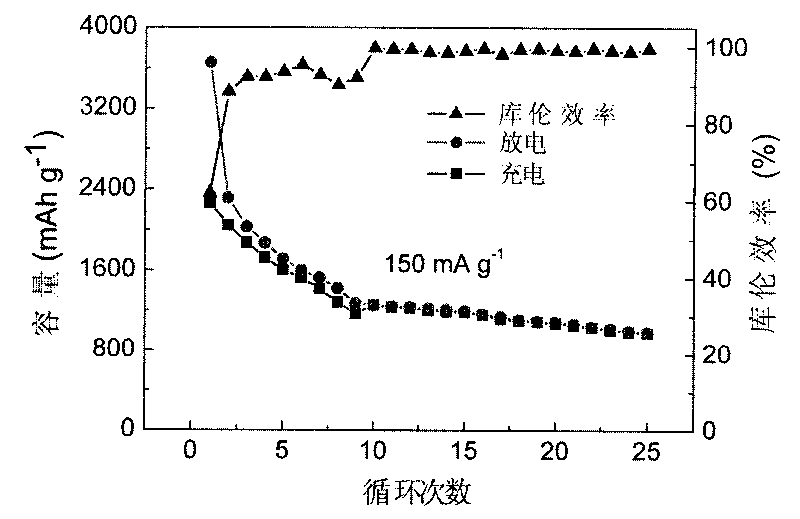

[0023] (3) After the etching is finished, both surfaces of the silicon wafer are silicon nanowire arrays with a length of 50 μm, and the middle is a silicon wafer with a thickness of 100 μm that is not corroded. The silicon nanowires on both sides are ground with fine sandpaper, and repeated ...

Embodiment 2

[0028] The steps of this embodiment are as follows:

[0029] (1) Put the monocrystalline silicon wafer into the aqueous solution of hydrofluoric acid and silver nitrate for 80s, the volume ratio of each component in the solution is: HNO 3 :HF:H 2 O=1:6:20, plate a layer of silver nanoparticle film with the method of electroless deposition;

[0030] (2) put the monocrystalline silicon chip that the surface is coated with silver nanoparticle film into the aqueous solution of hydrofluoric acid and hydrogen peroxide and corrode, the volume ratio of each component in the solution is: H 2 o 2 :HF:H 2 O=1:6:20, the corrosion temperature is 55°C, and the corrosion time is 85min;

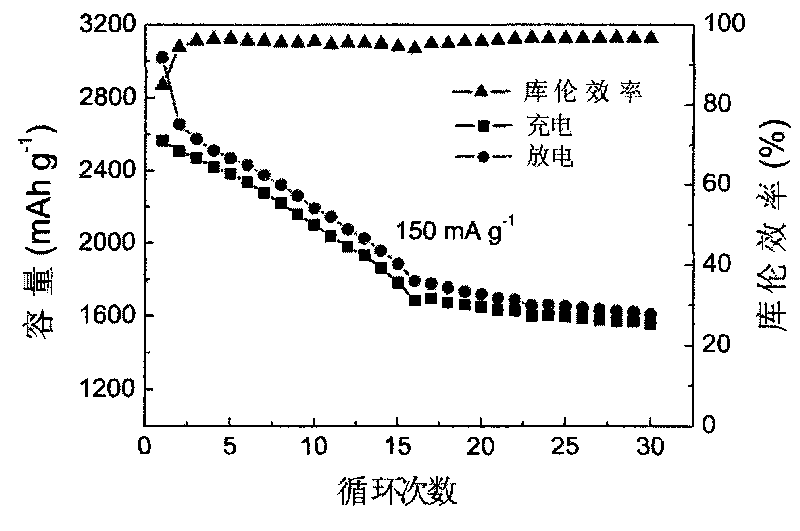

[0031] (3) After the etching is finished, both surfaces of the silicon wafer are silicon nanowire arrays with a length of 55 μm, and the middle is a silicon wafer with a thickness of 110 μm that is not corroded. The silicon nanowires on both sides are ground with fine sandpaper, and repeated after cleani...

Embodiment 3

[0036] The steps of this embodiment are as follows:

[0037] (1) Put the monocrystalline silicon wafer into the aqueous solution of hydrofluoric acid and silver nitrate for 70s, the volume ratio of each component in the solution is: HNO 3 :HF:H 2 O=1:8:26, plate a layer of silver nanoparticle film with the method of electroless deposition;

[0038] (2) put the monocrystalline silicon chip that the surface is coated with silver nanoparticle film into the aqueous solution of hydrofluoric acid and hydrogen peroxide and corrode, the volume ratio of each component in the solution is: H 2 o 2 :HF:H 2 O=1:8:26, the corrosion temperature is 60°C, and the corrosion time is 80min;

[0039](3) After the etching is finished, both surfaces of the silicon wafer are silicon nanowire arrays with a length of 60 μm, and the middle is a silicon wafer with a thickness of 120 μm without corrosion. The silicon nanowires on both sides are ground away with fine sandpaper, and repeated after clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com