Method for preparing epoxy resin with biphenyl structure

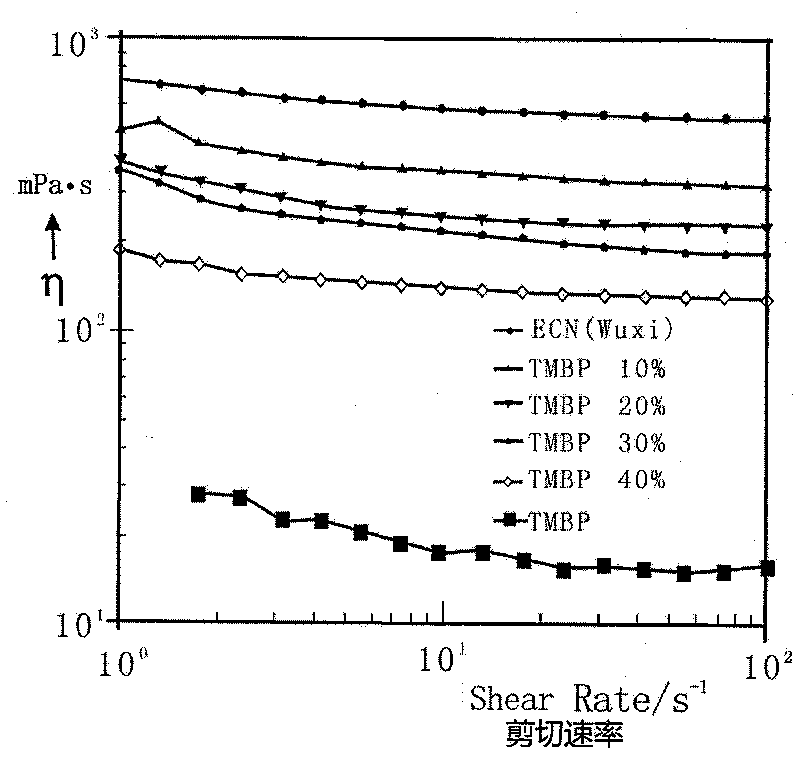

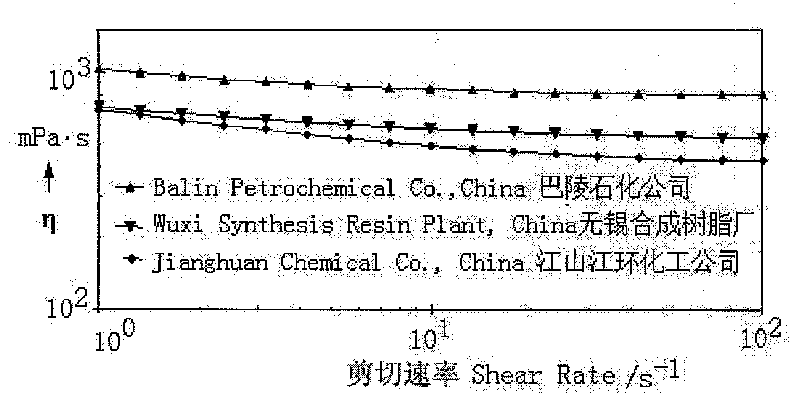

A technology of epoxy resin and biphenyl structure, which is applied in the field of preparation of epoxy resin containing biphenyl structure, can solve the problems of epoxy resin preparation process parameters and low thermal conductivity without disclosing biphenyl structure, and solve the problem of encapsulation Effects of cracks, low melt viscosity, and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The embodiment of the present invention provides a method for preparing an epoxy resin containing a biphenyl structure, comprising the following steps:

[0028] Put 0.01-1 mole of phase transfer catalyst into the reaction vessel, add 2-5 moles of absolute ethanol to dissolve it, then add 5-100 moles of biphenol and 10-200 moles of epichlorohydrin, Heat to 50-110°C, stir and react for 3-15 hours, add half of the NaOH solution with a total mole number of 0.1-5, react for 3-15 hours, then add the remaining half of the NaOH solution, under vacuum at -0.09MPa Distill under reduced pressure to remove excess epichlorohydrin to obtain a light yellow product; after dissolving the light yellow product in a solvent, add a decolorizing agent, filter with suction, freeze and recrystallize the filtrate at low temperature, filter with suction again, and wash with deionized water for 2~ 3 times, after vacuum drying, the light yellow crystal is obtained, which is the epoxy resin contain...

Embodiment 2

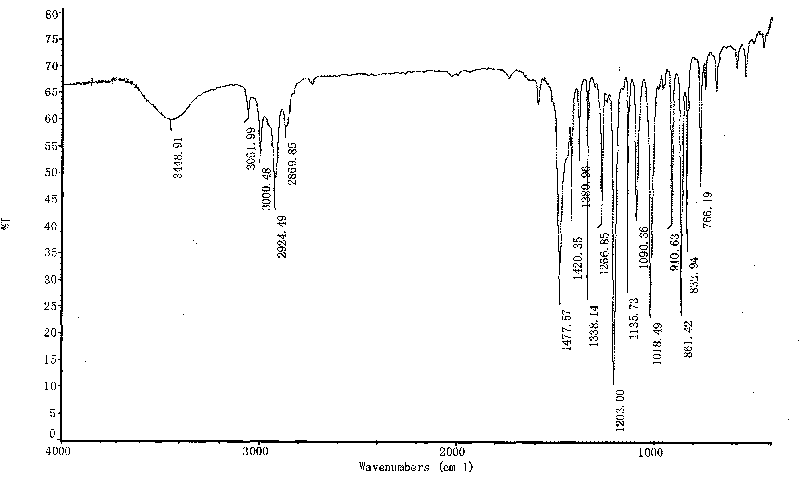

[0068] Get epichlorohydrin 187.4ml, diphenol 29.04g, ethanol 12ml, use 18-crown-6 ether as a phase transfer catalyst, the addition is 0.1g, add NaOH solution twice, add 8g concentration for the first time 30% NaOH, adding 8g concentration for the second time is 15% NaOH, and temperature of reaction is 85 ℃, and total reaction time is 6 hours, after reaction finishes, depressurizes and distills excess epichlorohydrin, and product uses methyl alcohol: acetone= Dissolve in a 2:1 (volume ratio) mixed solvent, add activated carbon for decolorization, filter with suction, and then dissolve with methanol: acetone = 2:1 (volume ratio) mixed solvent, place the solution in a freezing water bath at -10°C, cool and crystallize for 3 hours , after suction filtration, wash 3 times with deionized water at room temperature, and dry the product in a vacuum oven at 60° C. for 8 hours to finally obtain a biphenyl-containing epoxy resin with a yield of 93%. The epoxy equivalent of this biphenyl-c...

Embodiment 3

[0070] Take 187.4ml of epichlorohydrin, 29.04g of biphenol, and 12ml of ethanol, use 18-crown-6 ether as a phase transfer catalyst, the addition amount is 0.2g, add NaOH in two times, the concentration of adding 8g for the first time is 30 % NaOH, adding 8g concentration for the second time is 15% NaOH, and temperature of reaction is 80 ℃, and total reaction time is 8 hours, after having reacted, decompression evaporates excessive epichlorohydrin, and product uses butanol: acetone= Dissolve in a 1:1 (volume ratio) mixed solvent, add activated carbon for decolorization, filter with suction, then dissolve with butanol: acetone = 1:1 (volume ratio) mixed solvent, place the solution in a freezing water bath at -20°C, cool and crystallize for 1 hour, suction filtration, and the product after washing 3 times with deionized water at room temperature was dried in a vacuum oven at 60° C. for 8 hours to finally obtain a biphenyl-containing epoxy resin with a yield of 90%. The epoxy equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com