Method for preparing anode active substance, anode active substance, anode and battery

A positive electrode active material and positive electrode technology, applied in the field of method and the positive electrode active material prepared by the preparation method, can solve the problems of toxicity, less cobalt resources, difficult synthesis and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a method for preparing a positive electrode active material, wherein the preparation method includes sintering a mixture, the mixture contains a raw material 1 and a raw material 2, the raw material 1 contains a lithium source, an iron source and a phosphorus source, and the The second raw material is LiD c o 2 , Li i Ni 1-d-e co d mn e o 2 、LiNi 1-f-g co f al g o 2 , Li x Ni 1-y CoO 2 and Li m mn 2-n E. n o j One or more of the compounds indicated, wherein, D is one of B, Mg, Al, Ti, Cr, Fe, Cu, Zn, Ga, Y, La, V, 0<c≤3; 0.9 ≤i≤1.2, 0≤d≤0.5, 0<e≤0.3; 0≤f≤0.5, 0≤g≤0.3; 0.9≤x≤1.1, 0≤y≤1; E is boron, magnesium, aluminum, gallium And one of transition metal elements other than Mn, 0.9≤m≤1.1, 0≤n≤1, 1<j<6; the lithium source is capable of sintering with iron source and phosphorus source to obtain lithium ferrous phosphate Lithium-containing material, the sintering conditions make the obtained positive electrode active material...

Embodiment 1

[0046] Lithium carbonate, ferrous oxalate, and ammonium dihydrogen phosphate are mixed uniformly in a molar ratio of Fe:Li:P=1:1:1, and then lithium carbonate and LiNiO 2 The molar ratio of LiNiO is 1:0.02 (calculated as lithium atoms) 2 , and according to the amount of carbon content in the positive electrode active material generated is 5% by weight, add starch as a carbon source, ball mill for 10 hours, dry the ball-milled mixture at 80°C, and then dry the dried powder in a nitrogen atmosphere The temperature was raised to 600°C at 10°C / min, and sintered at a constant temperature for 20 hours to obtain the positive electrode active material LiFePO 4 / LiNiO 2 / C mixed crystals.

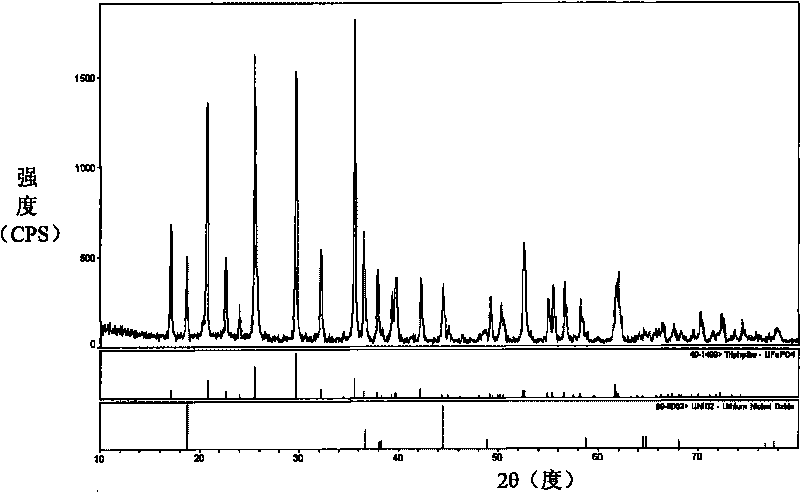

[0047] The XRD diffraction pattern of this positive electrode active material measured by the D / MAX-2200 / PC type X-ray powder diffractometer of Rigaku company is as follows figure 1 shown, from figure 1 It can be seen that in the diffraction peaks of the positive active material obtained after s...

Embodiment 2

[0049]Lithium oxalate, ferric oxide, and diammonium hydrogen phosphate were mixed uniformly in a molar ratio of Fe:Li:P=1:0.95:1.1, and then lithium oxalate and LiCoO 2 The molar ratio is 1:0.04 (calculated as lithium atoms) by adding LiCoO 2 , and add acetylene black as a carbon source according to the content of carbon in the positive electrode active material generated as 2% by weight, ball mill for 10 hours, dry the ball-milled mixture at 80°C, and then dry the dried powder in nitrogen Under the atmosphere, the temperature was raised to 500°C at 5°C / min, and sintered at a constant temperature for 30 hours to obtain the positive electrode active material LiFePO 4 / LiCoO 2 / C mixed crystals.

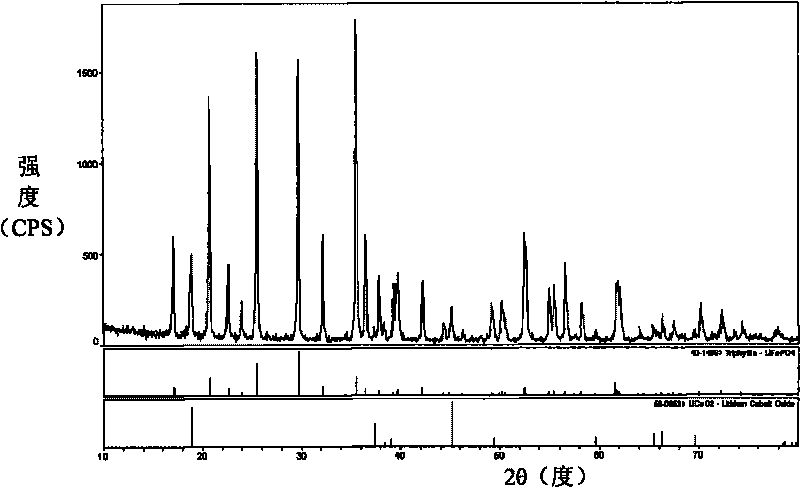

[0050] The XRD diffraction pattern of this positive electrode active material measured by the D / MAX-2200 / PC type X-ray powder diffractometer of Rigaku company is as follows figure 2 shown, from figure 2 It can be seen that in the diffraction peaks of the positive active material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com