Completely biodegraded polylactic acid nanometer composite material and preparation method thereof

A nanocomposite material and biodegradation technology, which is applied in the field of modification and processing of biodegradable polymer materials, can solve the problems of affecting the biodegradation performance of composite materials, the decrease of toughness of composite materials, and the small increase in toughness, etc. The effect of large-scale production, high tensile strength, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

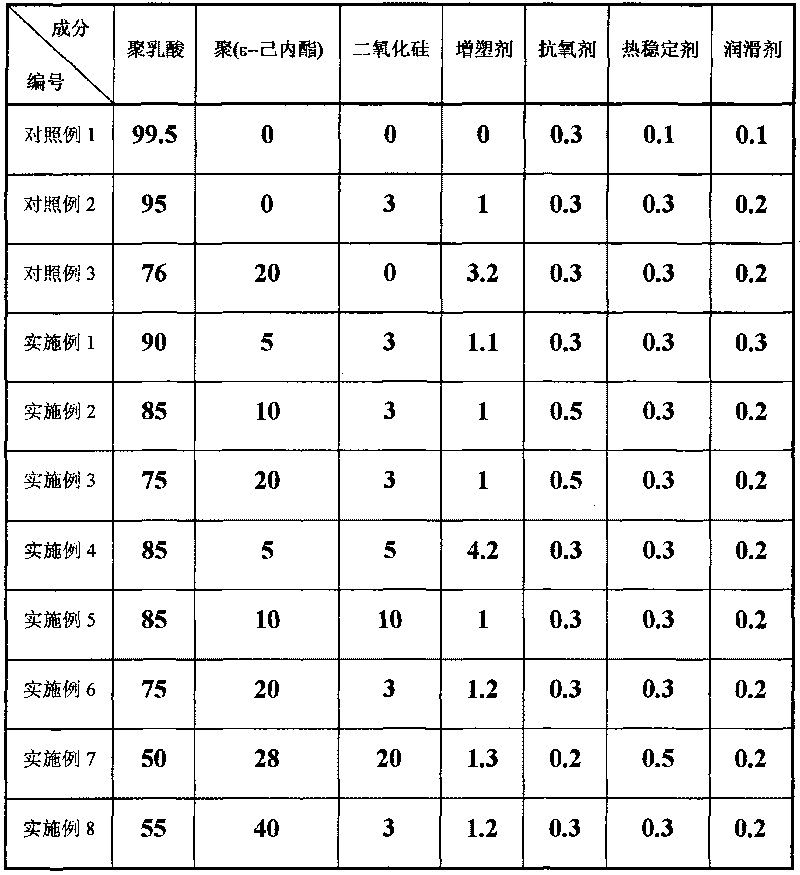

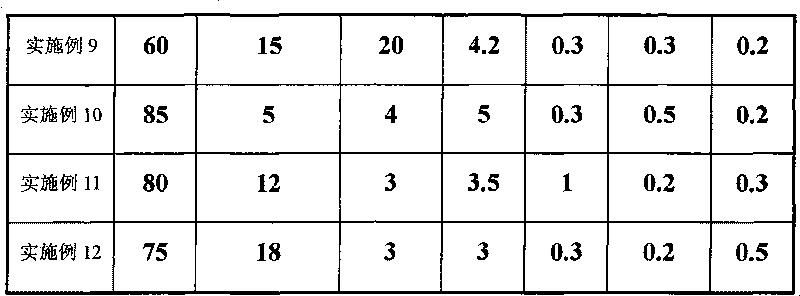

[0042] A, pre-mixing: take raw materials according to the proportioning of the mass parts of Example 1-3 in Table 1 and the technical index of explanation, put into high-speed mixer and stir evenly; The speed of described high-speed mixer is 300 rpm;

[0043] B. Mixing: Put the above-mentioned uniformly stirred materials into an ordinary internal mixer, 175°C, 60 rpm, and mix for 10 minutes;

[0044]C. Hot press molding: hot press the above-mentioned products after further mixing into sheets on a flat vulcanizing machine; the thickness of the sheets is 1.0 mm and 4 mm; the hot press molding temperature is 190 ° C, and the pressure is 10 MPa .

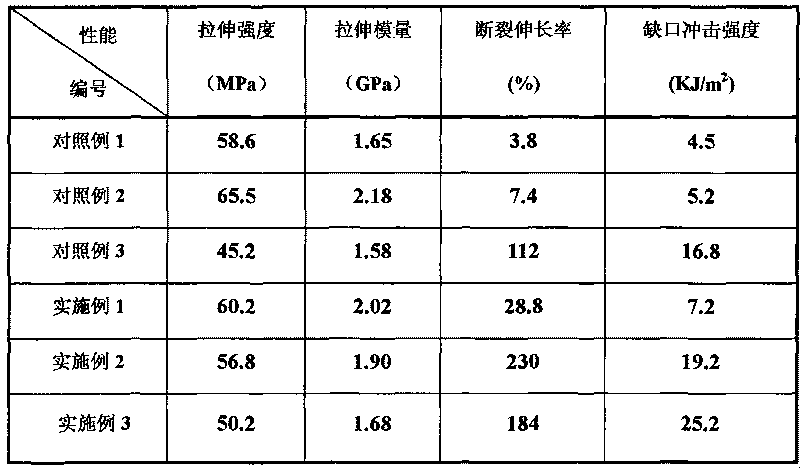

[0045] The prepared sheet was subjected to tensile and notched impact tests, the sample size was the same as that of Comparative Example 1, and the measured mechanical properties are shown in Table 2.

Embodiment 4-7

[0047] A, premixing: take the raw materials according to the proportioning of the mass parts of Examples 4-7 in Table 1 and the technical index of explanation, put into the high-speed mixer and stir evenly; The speed of the high-speed mixer is 500 rpm;

[0048] B. Mixing: Put the above-mentioned uniformly stirred materials into an ordinary internal mixer, 175°C, 60 rpm, and mix for 5 minutes;

[0049] C. Hot press molding: hot press the above-mentioned products after further mixing into sheets on a flat vulcanizing machine; the thickness of the sheets is 1.0 mm and 4 mm; the hot press molding temperature is 190 ° C, and the pressure is 10 MPa .

[0050] The prepared sheet was subjected to tensile and notched impact tests, the sample size was the same as that of Comparative Example 1, and the measured mechanical properties are shown in Table 2.

Embodiment 8

[0052] A, premixing: take the raw material according to the proportioning of the mass parts of Example 8 in Table 1 and the technical index of explanation, put into the high-speed mixer and stir evenly; The speed of the high-speed mixer is 200 rpm;

[0053] B. Extrusion granulation: Put the above-mentioned mixed sample into a twin-screw extruder to extrude granulation. The processing temperature conditions are: Zone 1: 70°C; Zone 2: 140°C; Zone 3: 150°C; Zone 4: 165°C; Zone 5: 175°C; Zone 6: 185°C; Zone 7: 180°C; Connector: 170°C; Head: 170°C, screw speed 15HZ;

[0054] C. Hot press molding: hot press the above-mentioned products after further mixing into sheets on a flat vulcanizing machine; the thickness of the sheets is 1.0 mm and 4 mm; the hot press molding temperature is 190 ° C, and the pressure is 10 MPa .

[0055] The prepared sheet was subjected to tensile and notched impact tests, the sample size was the same as that of Comparative Example 1, and the measured mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com