Method for preparing tin oxide single crystal film with orthogonal structure

A single crystal film and tin oxide technology is applied in the field of preparation of orthogonal structure tin oxide single crystal film to achieve the effects of good uniformity and repeatability, less lattice defects and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

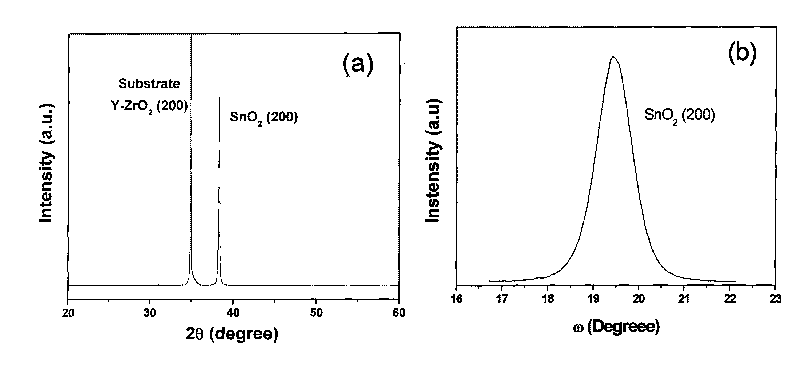

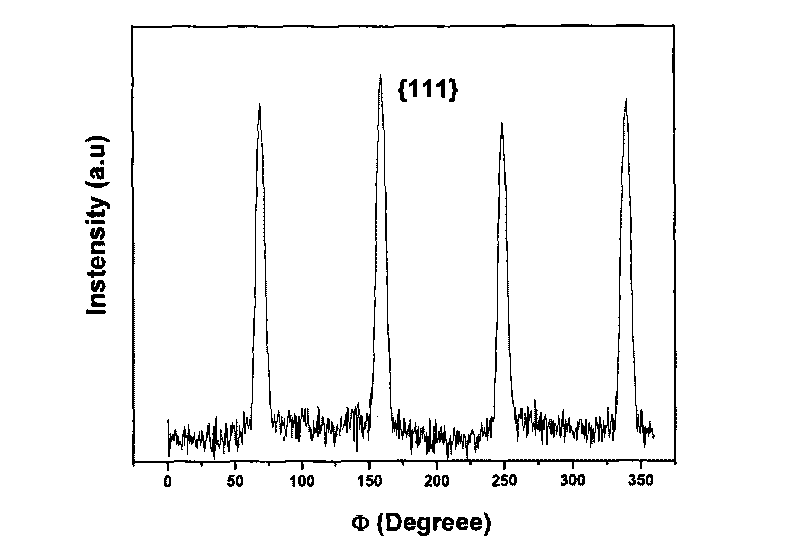

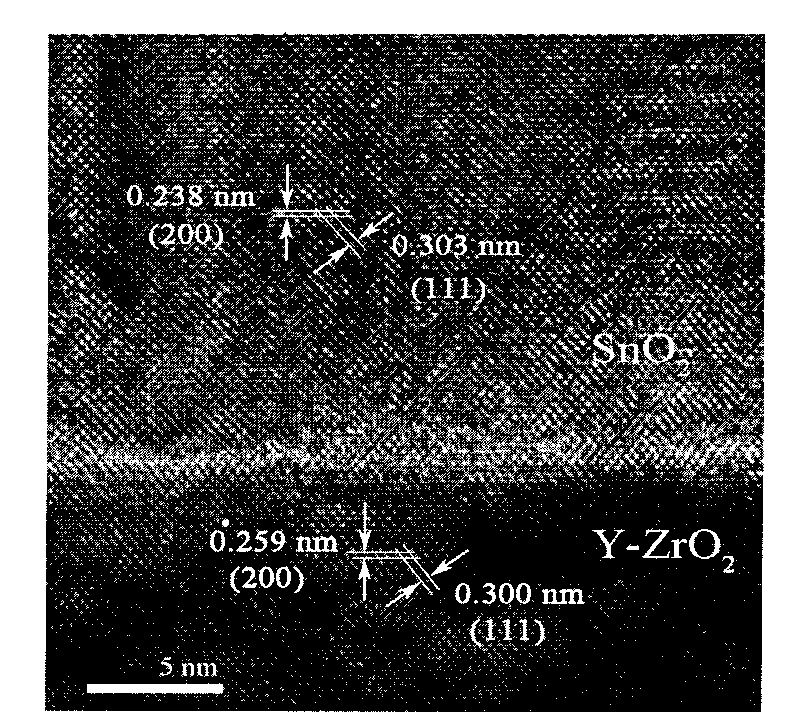

[0042] Embodiment 1: Orthogonal structure tin oxide single crystal thin film material was prepared by MOCVD technology.

[0043] (1) First pump the reaction chamber of the MOCVD equipment to a high vacuum state of 5×10 -4 Pa, heat the substrate to 600°C;

[0044] (2) Open the valve of the nitrogen cylinder and feed nitrogen into the reaction chamber (background N 2 )300sccm, 30 minutes, make reaction chamber pressure be 120Torr;

[0045] (3) Open the valve of the oxygen cylinder, adjust the flow rate of oxygen to 30 sccm, and keep it for 10 minutes;

[0046] (3) Open the valve of the tin source bottle, adjust the flow rate of the carrier gas (nitrogen) to 30 sccm, and keep it for 10 minutes;

[0047] (4) Pass oxygen and organometallic tin sources into the reaction chamber simultaneously, and keep the film growth time as 300 minutes;

[0048] (5) Close the valves of the tin source bottle and the oxygen bottle after the reaction, and flush the pipeline with nitrogen for 20 m...

Embodiment 2

[0058] Single crystal tin oxide thin film materials were prepared by MOCVD technology. The preparation process is the same as in Example 1, except that the reaction chamber pressure is 40 Torr, the organometallic source temperature is 20°C, the organometallic source carrier gas flow rate is 40 sccm, the oxygen flow rate is 25 sccm, and the background N 2 The flow rate is 300 sccm, and the film growth time is 120 minutes. The double-sided polished yttrium-doped zirconia single crystal (100) surface is used as the substrate material, Sn(C 2 h 5 ) 4 As an organometallic source, the tin oxide film prepared at a substrate temperature (growth temperature) of 650°C is a single crystal film with an orthogonal structure, the thickness of the film is 210nm, and the carrier mobility of the film is 42cm 2 V -1 the s -1 , the average relative transmittance in the visible light range exceeds 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com