Gold-nanoparticle-supported cubic mesoporous titanium oxide composite film and preparation thereof

A technology of gold nanoparticles and titanium oxide thin films, applied in instruments, nonlinear optics, optics, etc., to achieve uniform spatial distribution, wide application value, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of ordered cubic mesoporous titanium oxide film:

[0042] Get 0.5g surfactant F127 (molecular formula is EO 106 PO 70 EO 106 ; wherein EO represents ethoxy, PO represents propoxy) was dissolved in 20.0g of ethanol, stirring. At the same time, 0.5 g of acetylacetone, 3.4 g of butyl titanate and 2.8 g of aqueous hydrochloric acid solution with a molar concentration of 26% were mixed and stirred. After 2 hours, mix the two solutions, continue to stir for 2 hours, place the obtained sol in an environment with a relative humidity of 85%, and dip and pull to form a film at a pulling speed of 70 cm / min.

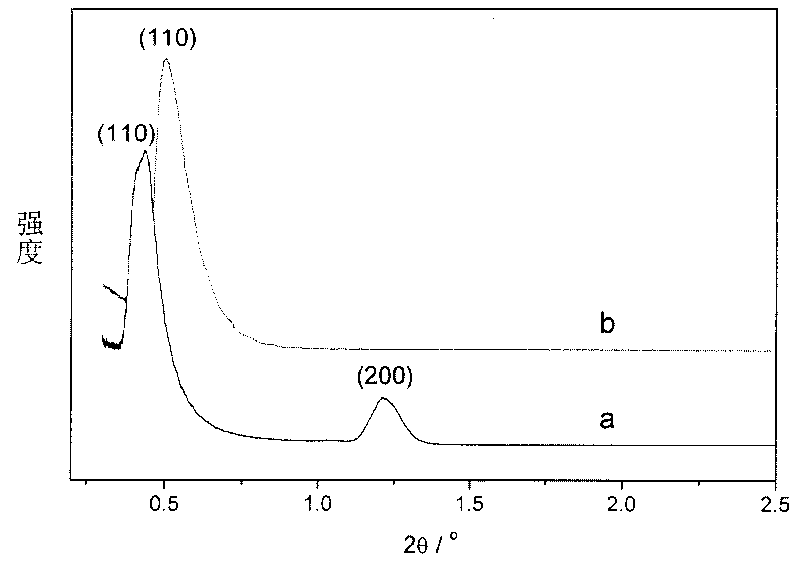

[0043] After drying at room temperature for 24 hours, the small angle XRD pattern of the film is as follows figure 1 As shown in curve (a) in , the diffraction peak in curve (a) corresponds to the (110) plane and (200) diffraction peak of the cubic mesoporous phase.

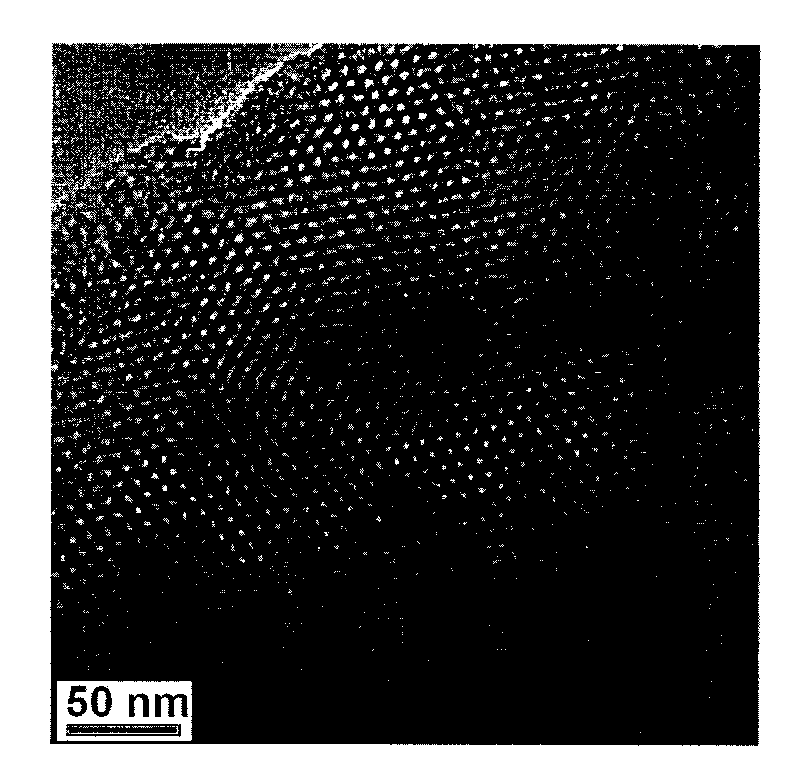

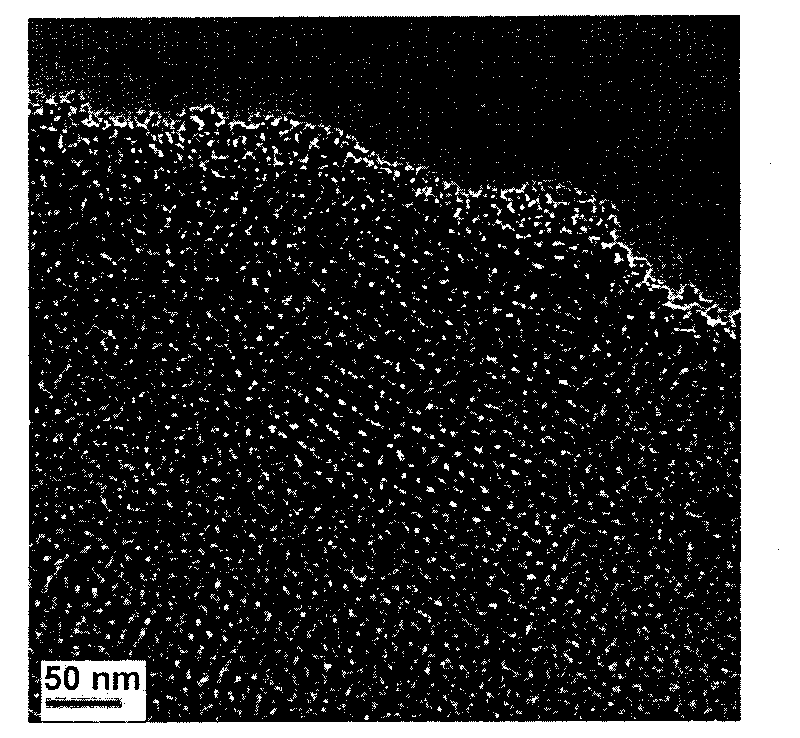

[0044] Transmission electron micrographs as figure 2 as shown, figure 2 The cubic mes...

Embodiment 2

[0055] 1. Preparation of ordered cubic mesoporous titanium oxide film:

[0056] Dissolve 0.5g of surfactant F127 in 20.0g of ethanol and stir. At the same time, 0.5 g of acetylacetone, 3.4 g of butyl titanate and 2.8 g of aqueous hydrochloric acid solution with a molar concentration of 28% were mixed and stirred. After 2 hours, mix the two solutions, continue to stir for 2 hours, place the obtained sol in an environment with a relative humidity of 85%, and dip and pull to form a film at a pulling speed of 70 cm / min. The cubic mesoporous titanium oxide film has a cubic mesoporous structure, and its thickness is 118nm. Detected by a BET detector, the pore diameter of the ordered cubic mesoporous titanium oxide film prepared in this example is 7.3nm; the pore volume is 0.16cm 3 / g.

[0057] 2. Preparation of cubic mesoporous titanium oxide composite film supported by gold nanoparticles:

[0058] Heat treatment: After drying at room temperature, the ordered cubic mesoporous ti...

Embodiment 3

[0064] 1. Preparation of ordered cubic mesoporous titanium oxide film:

[0065] Dissolve 0.5g of surfactant F127 in 20.0g of ethanol and stir. At the same time, 0.5 g of acetylacetone, 3.4 g of butyl titanate and 2.8 g of aqueous hydrochloric acid solution with a molar concentration of 26-28% were mixed and stirred. After 2 hours, mix the two solutions, continue to stir for 2 hours, place the obtained sol in an environment with a relative humidity of 85%, and dip and pull to form a film at a pulling speed of 70 cm / min. The cubic mesoporous titanium oxide film has a cubic mesoporous structure, and its thickness is 118nm. Detected by a BET detector, the pore diameter of the ordered cubic mesoporous titanium oxide film prepared in this example is 7.3nm; the pore volume is .0.16cm 3 / g.

[0066] 2. Preparation of cubic mesoporous titanium oxide composite film supported by gold nanoparticles:

[0067] Heat treatment: After drying at room temperature, the ordered cubic mesoporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com