Two-section method for preparing synthetic gas with biomaterial

A technology for synthesis gas and biomass, which is applied in the production of combustible gas, granular/powder fuel gasification, energy input, etc., can solve problems such as tedious purification process, and achieve the effect of simplifying process, improving operation stability and facilitating control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

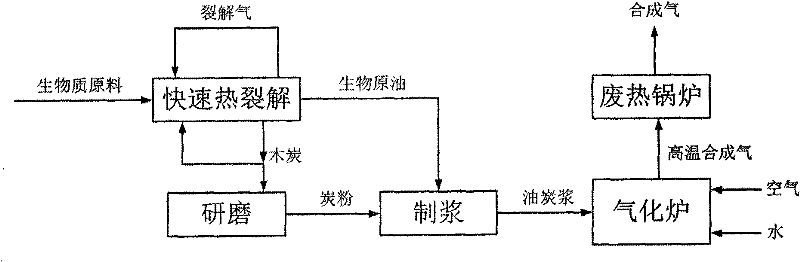

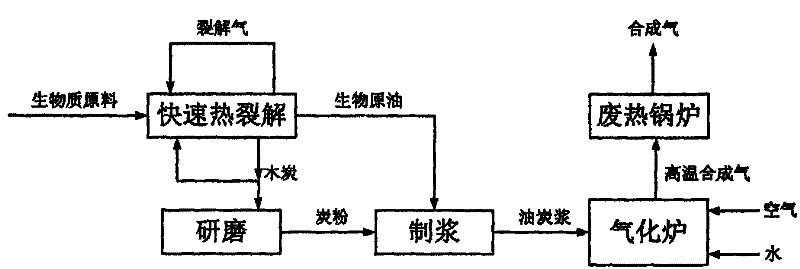

[0024] combine figure 1 As shown, the biomass raw material is broken into particles below 2mm after being dried, and sent to the normal pressure fluidized bed rapid pyrolysis reactor (hereinafter referred to as the pyrolyzer) by the screw conveyor, and the temperature of the pyrolyzer is controlled at 500°C. After the steam product of the pyrolyzer is cooled to 40°C, the bio-crude oil and water leave the condenser in the form of liquid, and all the non-condensable gas is recycled back to the pyrolyzer as part of the fuel required by the pyrolyzer, and the bio-crude oil and water are decanted After being separated in the container, it enters the pulping tank. After the pyrolyzed solid product charcoal leaves the pyrolyzer, it is ground to less than 200 microns, and sent to a slurry tank to mix with bio-crude oil to prepare oil-charcoal slurry. The weight ratio of bio-crude oil to charcoal powder is 3.25:1. The bio-crude water content is 20%, the dry basis weight composition is...

Embodiment 2

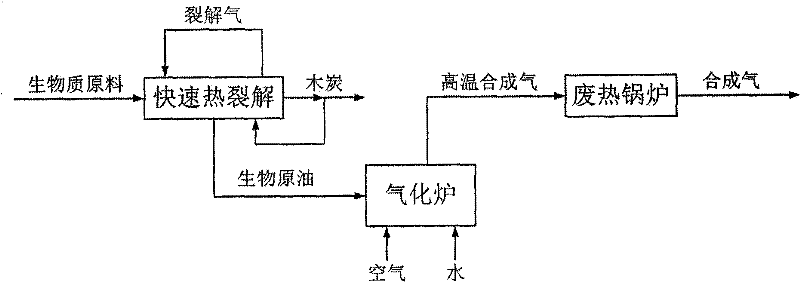

[0026] It can be seen from Example 1 that the obtained charcoal can be used in whole to prepare oil-charcoal slurry, and can also be used in part to prepare oil-charcoal slurry, and partly can be used for other purposes, such as fuel for a pyrolyzer to maintain the pyrolysis temperature. combine figure 2 As shown, Embodiment 2 is an extension of Embodiment 1. All the charcoal prepared by pyrolysis of biomass is used for other purposes, and is not sent to the gasifier to prepare synthesis gas. For this case, the bio-crude oil can be directly pumped into the gasifier for gasification without pulping. Other than that, there is no difference from the process in Embodiment 1 in other respects.

[0027]A feature of the present invention is that biomass solids are converted into bio-crude oil liquid and charcoal by using atmospheric pressure methods such as rapid thermal cracking, and the oil-charcoal slurry prepared by suspending ground charcoal powder in bio-crude oil can be dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com