A method for anti-corrosion treatment of marine climate-resistant engineering parts

A marine climate and anti-corrosion treatment technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of surface shape, difficult size control, difficult to handle large-area parts, high cost of vapor deposition, etc., to achieve The effect of low material cost, reduced mechanical property mismatch, and eliminated risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050](1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0051] (2) Etch the degreasing and rust-removing parts in a mixed solution of hydrochloric acid HCl 94% (volume fraction) + hydrofluoric acid HF 6% (volume fraction), at room temperature for 1 minute, and rinse with deionized water.

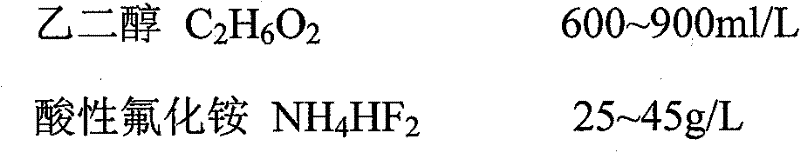

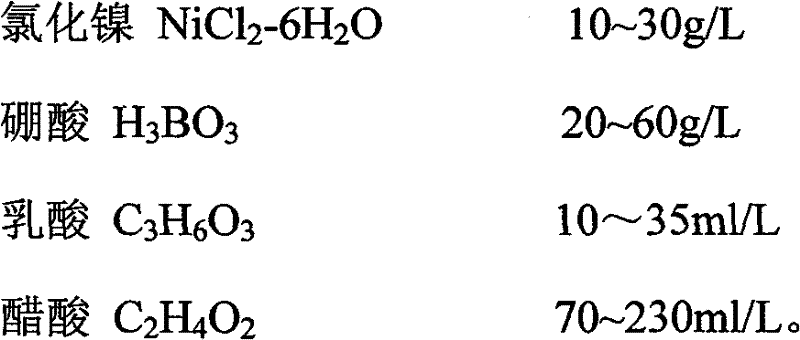

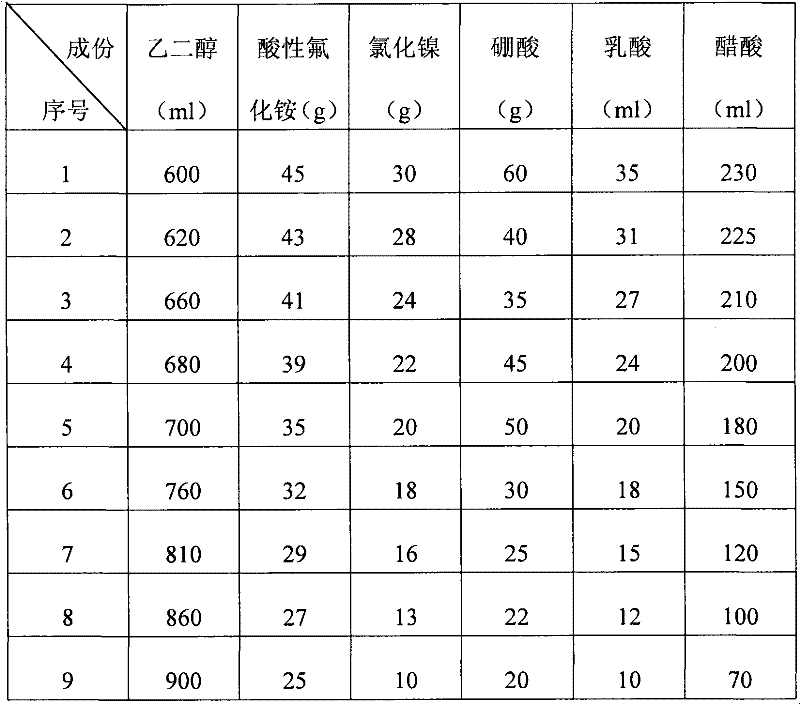

[0052] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 40°C for 40 minutes, rinsed with deionized water, and dried.

[0053] (4) Put the parts treated in (1) to (3) into the atmosphere protection furnace, and preheat at 500°C for 20 minutes.

[0054] (5) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 1 minute, and rotate the parts during the immersion process.

[0055] (6) Put the immersion-plated parts into a vacuum furnace, keep w...

Embodiment 2

[0058] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0059] (2) The parts after degreasing and derusting are etched in a mixed solution of hydrochloric acid HCl 95% (volume fraction) + hydrofluoric acid HF 5% (volume fraction) at room temperature for 2 minutes, and rinsed with deionized water.

[0060] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 50°C for 35 minutes, rinsed with deionized water, and dried.

[0061] (4) Put the parts treated in (1) to (3) into the atmosphere protection furnace, and preheat at 600°C for 15 minutes.

[0062] (5) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 3 minutes, and rotate the parts during the immersion process.

[0063] (6) Put the immersion-plated parts into a vacuum furn...

Embodiment 3

[0066] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0067] (2) The parts after degreasing and derusting are etched in a mixed solution of hydrochloric acid HCl 96% (volume fraction) + hydrofluoric acid HF4% (volume fraction) at room temperature for 3 minutes, and rinsed with deionized water.

[0068] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 60°C for 30 minutes, rinsed with deionized water, and dried.

[0069] (4) Put the parts treated in (1) to (3) into the atmosphere protection furnace, and preheat at 650°C for 10 minutes.

[0070] (5) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 5 minutes, and rotate the parts during the immersion process.

[0071] (6) Put the immersion-plated parts into a vacuum furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com