Method for preparation of patterning colloid photonic crystal by ink-jet printing

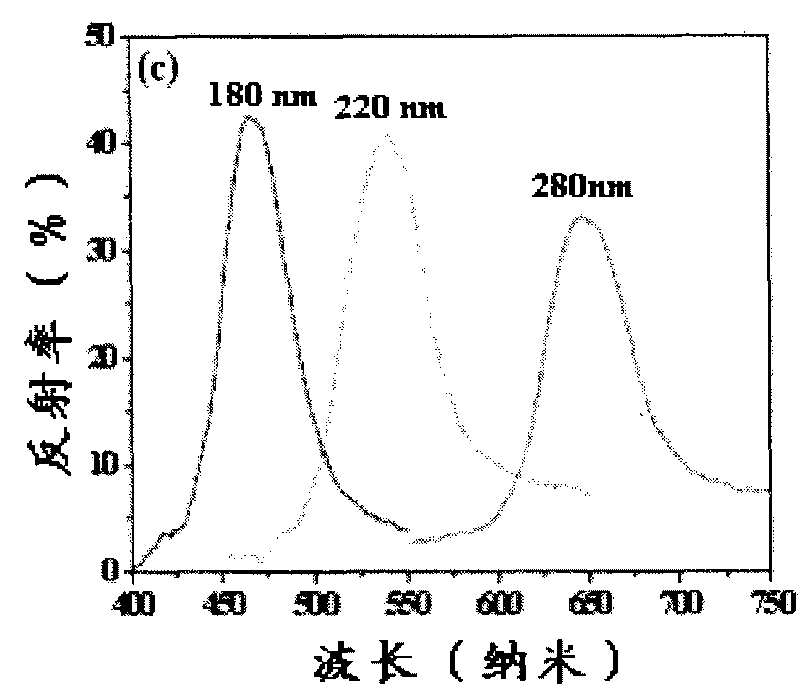

A colloidal photonic crystal and inkjet printing technology, which is applied to the surface coating liquid device, coating, special surface, etc., can solve the problems of poor optical performance and achieve good optical performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

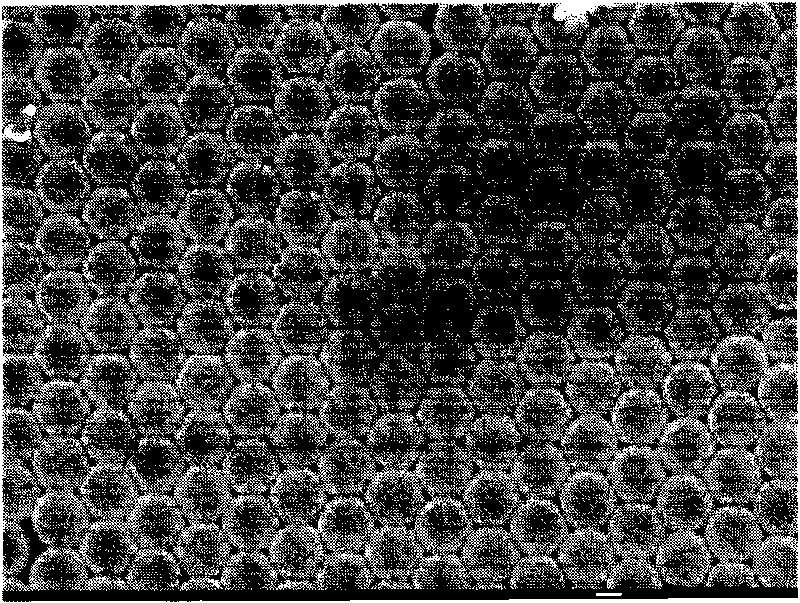

Image

Examples

Embodiment 1

[0040] The preparation of monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 50nm is as follows:

[0041] The monomer mixture methyl methacrylate (1.2 g), styrene (18 g) and acrylic acid (1.2 g), pH buffer (1.0 g) and emulsifier sodium dodecyl sulfonate (0.0786 mg) were dissolved in In water (100 mL), the resulting mixed system was stirred and mixed at 600 rpm, and heated to 75°C. Add 10 ml of potassium persulfate (0.8 g dissolved in 20 ml of water) aqueous solution to start the reaction, add 5 ml of potassium persulfate aqueous solution after 3.5 hours of reaction, and add the remaining potassium persulfate aqueous solution after the reaction continues for 3 hours. The reaction then continued for 2 hours and then ended. Finally, polystyrene-polymethyl methacrylate-polyacrylic acid triblock monodisperse polymer latex particles (monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles) with a particle size of 50 ...

Embodiment 2

[0044] The preparation method of monodisperse poly(methylstyrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 300nm is as follows: the monomer mixture methyl methacrylate (1.2 g), methyl styrene (18 g) ), acrylic acid (1.2 g), and pH buffer (1.0 g) were dissolved in water (100 mL), and the resulting mixed system was stirred and mixed at 600 rpm and heated to 75°C. Add 10 ml of potassium persulfate (0.8 g dissolved in 20 ml of water) aqueous solution to start the reaction, add 5 ml of potassium persulfate aqueous solution after 3.5 hours of reaction, and add the remaining potassium persulfate aqueous solution after the reaction continues for 3 hours. The reaction then continued for 2 hours and then ended. Finally, polymethylstyrene-polymethylmethacrylate-polyacrylic acid triblock monodisperse polymer latex particles with a particle size of 300nm (monodisperse poly(methylstyrene-methylmethacrylate-acrylic acid) latex grain).

[0045] At room temperatu...

Embodiment 3

[0048] At room temperature (20℃~30℃), respectively configure a monodisperse silica latex particle with a surface tension of 60mN / m and a particle size of 215nm with a concentration of 10wt% (purchased from Fujian Fina Materials Co., Ltd.) , 10wt% of glycerol and 80wt% of water composed of monodisperse latex particles; and another surface tension of 45mN / m by a concentration of 10wt% of monodisperse polystyrene latex particles with a particle size of 300nm (Purchased by Zhejiang Yiyi Nano Laboratory), an emulsion of monodisperse latex particles composed of 10 wt% glycerol and 80 wt% water. The above-mentioned two kinds of emulsions containing monodisperse latex particles were respectively installed in two ink cartridges of an inkjet printer; after the inkjet printer, the contact angle of the above-mentioned two kinds of monodisperse latex particle emulsion inks was coated with polycarbonate with a contact angle of 70° After pattern printing and drying on the coated aluminum plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com