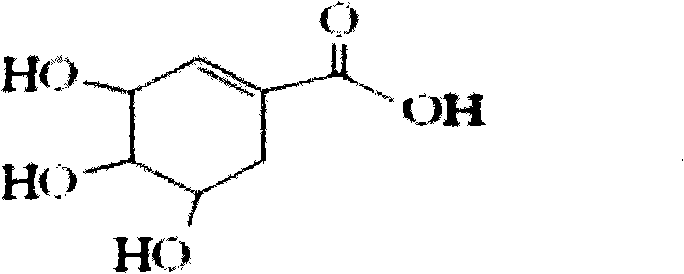

Preparation method of shikimic acid

A technology of shikimic acid and ultrafiltration membrane, which is applied in the field of shikimic acid extraction and purification technology, can solve the problems of inability to concentrate shikimic acid crystal concentration, low enrichment degree of molecular substances, corrosion of stainless steel concentrator, etc., and achieve short cycle and low cost , The effect of less dissolution of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100kg star anise (shikimic acid content 9%), grind it into 40 mesh, add 500L water, heat to 50°C, stir and extract for 1 hour, extract twice, combine the extracts, filter, add microfiltration membrane system to filter and then pass through the interception The ultrafiltration membrane with a molecular weight of 1000-3000 collects the permeate. The permeate was added to 20L D201 ion exchange resin column for adsorption, first washed with deionized water until neutral, then 100L 5% sodium hydroxide aqueous solution was used to elute shikimic acid, the collected shikimic acid eluate was desalted through 001×7 cationic resin column, The collected column liquid was concentrated under reduced pressure with a graphite concentrator to a density of 1.5, and left to crystallize for 10 hours. The crystals were filtered to obtain 10 kg of crude crystals, which were refluxed with 90% methanol to dissolve, the methanol was recovered to 50 L under reduced pressure, left to crysta...

Embodiment 2

[0029] Take 100kg star anise (shikimic acid content 10%), crush it into 60 mesh, add 600L water, heat to 40°C, stir and extract for 2 hours, extract twice, combine the extracts, filter, add microfiltration membrane system to filter and then pass through the retention The ultrafiltration membrane with a molecular weight of 1000-3000 collects the permeate. The permeate was added to 20L 201×7 ion exchange resin column for adsorption, first washed with deionized water until neutral, then 80L 6% sodium hydroxide aqueous solution was used to elute shikimic acid, and the shikimic acid eluate was collected. 001×8 cation resin column for desalination, collect the column liquid and concentrate it to a density of 1.6 under reduced pressure with a graphite concentrator, and leave it to crystallize for 15 hours. The crystals were filtered to obtain 10.5 kg of crude crystals, which were refluxed with 99% methanol to dissolve, the methanol was recovered to 63 L under reduced pressure, left t...

Embodiment 3

[0031] Take 100kg star anise (shikimic acid content 9%), crush it to 50 mesh, add 550 g of water, heat to 40°C, stir and extract for 1 hour, extract three times, combine the extracts, filter, add microfiltration membrane system to filter and then pass through molecular weight cut off For 1000-3000 ultrafiltration membrane, collect the permeate. The permeate was added to 20L 201×7 ion exchange resin column for adsorption, first washed with deionized water until neutral, then 90L 5% sodium hydroxide aqueous solution was used to elute shikimic acid, and the shikimic acid eluate was collected through 001×7 cationic resin column for desalting, the collected column liquid was concentrated to a density of 1.5 under reduced pressure with a graphite concentrator, and left to crystallize for 16 hours. The crystals were filtered to obtain 10.3 kg of crude crystals, which were refluxed with 95% methanol to dissolve, the methanol was recovered to 60 L under reduced pressure, left to crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com