Grooved field-effect tube and preparation method thereof

A field effect transistor and trench technology, applied in the field of field effect transistors and trench field effect transistors, can solve the problems of increasing gate-drain capacitance Cgd, reducing switching speed, increasing switching power consumption, etc., and improving roughness. , The effect of improving device performance and improving switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

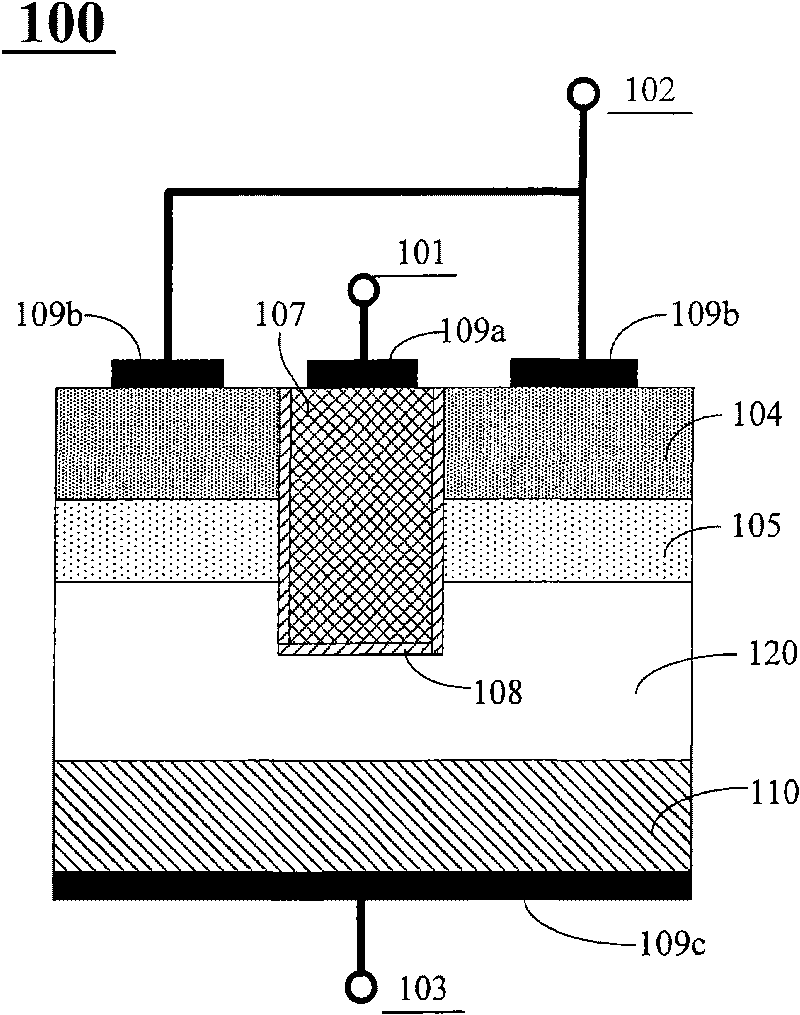

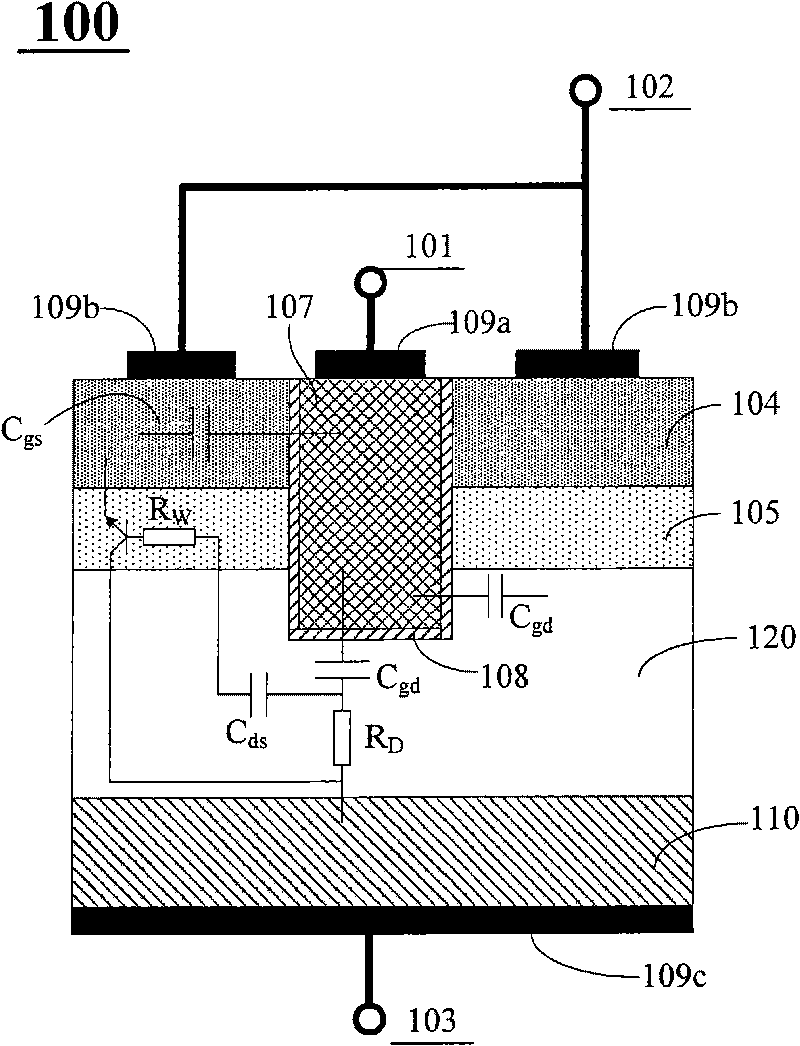

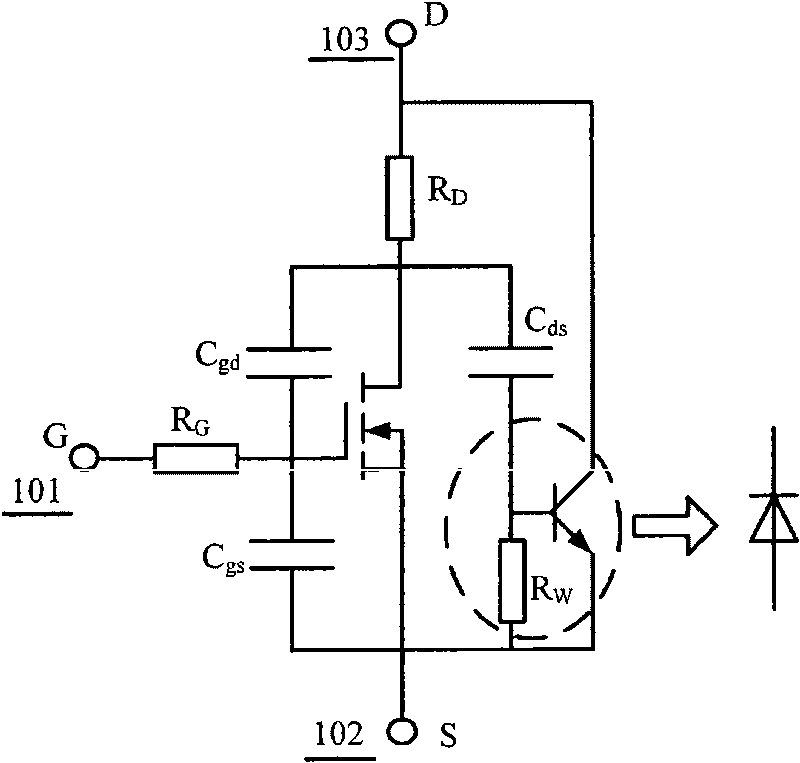

[0030] figure 2 It is a schematic cross-sectional structure diagram of the trenched field effect transistor provided by the present invention.

[0031] like figure 2 As shown, the trench FET 200 includes: a semiconductor substrate 210 of a first conductivity type and an epitaxial layer 220 of the first conductivity type covering its upper surface, and a source doping of the first conductivity type located in the epitaxial layer 210 Region 201 and channel region 202 of the second conductivity type, trench polysilicon gate 204 surrounded by source doping region 201 and channel region 202, respectively used to separate trench polysilicon gate 204 from the active region and the body region side spacers 207 and gate oxide layer 205, source / drain / gate electrodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com