Method for extracting athomin with mustard seeds as raw material

A mustard seed and horseradish technology, applied in the direction of fermentation, etc., can solve the problems of low yield, long time consumption of allyl isothiocyanate, low extraction rate, etc., and achieve short reaction time and outstanding substantive characteristics , the effect of high product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The method for extracting horseradish as raw material with mustard seeds of the present invention comprises the following steps:

[0017] A, prepare raw mustard seeds, and crush it to 20-40 mesh;

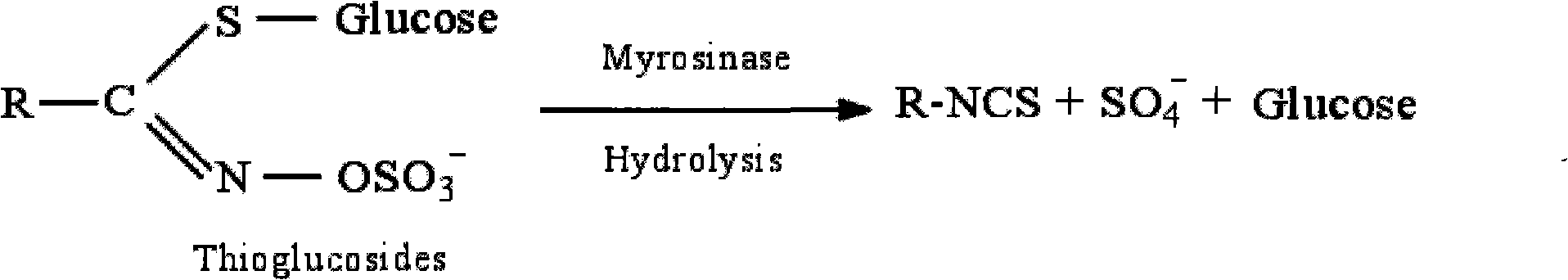

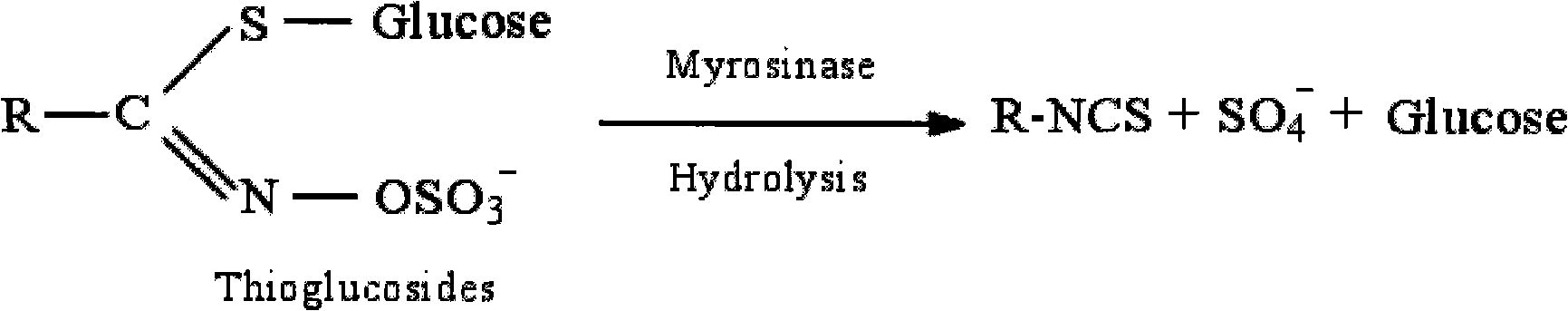

[0018] B. Add the crushed mustard seeds into the reaction kettle, soak the crushed mustard seeds for 1-4 hours with pH 4-6.5, temperature 30-80°C acidic aqueous solution, wherein the optimum temperature of the acidic aqueous solution is 50 DEG C, soak for 2 hours, the water for soaking the mustard seeds is preferably deionized water, adopt the existing technology to catalyze the glucosinolates (Thioglucosides) contained in the mustard seeds under the catalysis of glucosinolate enzyme (Myrosinase) Hydrolyzed to allyl isothiocyanate, wherein the acid regulator of the aqueous solution is acetic acid or lactic acid or malic acid or citric acid or gluconic acid or tartaric acid or fumaric acid or ascorbic acid, the weight ratio of mustard seed to water is 1:2 or 1 :2.5 or 1:3 or ...

Embodiment 2

[0022] Using mustard seeds as processing raw materials, first crush the mustard seeds into 20-40 meshes, then add to the reaction kettle, then add deionized water, the weight ratio of mustard seeds to deionized water is 1:6, adjust the deionized water with acetic acid The pH of the ionized water is pH4.5, and the temperature of the water is 40°C. The mustard seeds are soaked in the aqueous solution for 3 hours, so that the glucosinolates (Thioglucosides) contained in the mustard seeds are activated by the glucosinolate enzyme (Myrosinase). ) under catalysis to be hydrolyzed into allyl isothiocyanate, and then extract the product in the reaction kettle by subcritical water extraction at 1Mpa and 100°C for 50 minutes, and then separate the product in the reaction kettle to obtain crude horseradish. The content of allyl isothiocyanate in the detected product was 68.6%, and the oil yield was 1.9%.

Embodiment 3

[0024] Using mustard seeds as processing raw materials, first crush the mustard seeds into 20-40 meshes, then add to the reaction kettle, then add deionized water, the weight ratio of mustard seeds to deionized water is 1:4, adjust with citric acid The pH of the deionized water is pH 5, and the temperature of the water is 50°C. Soak the mustard seeds with the aqueous solution for 2 hours, so that the glucosinolates (Thioglucosides) contained in the raw materials are catalyzed by glucosinolate enzyme (Myrosinase). Hydrolyze to allyl isothiocyanate, then extract the product in the reaction kettle by subcritical water extraction at 2Mpa and 120°C for 40 minutes, and then separate the product in the reaction kettle to obtain crude horseradish. The content of allyl isothiocyanate is 68.2%, and the oil yield is 2.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com