Low-cost counter electrode for dye-sensitized solar battery

A technology of solar cells and dye sensitization, applied in the field of green renewable energy, can solve the problems of high price and limited platinum reserves, and achieve the effect of solving the problem of high price and resource shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation of embodiment 1 molybdenum carbide slurry

[0019] After mixing molybdenum carbide fine powder 300mg, titanium dioxide powder (P25, Degauss) 100mg, triton 100mg, isopropanol 5mL and zirconium baht 5g, ball milled for 4 hours, prepared into a spray slurry, heated to remove the organic solvent, Printing and knife coating pastes are then prepared.

Embodiment 2

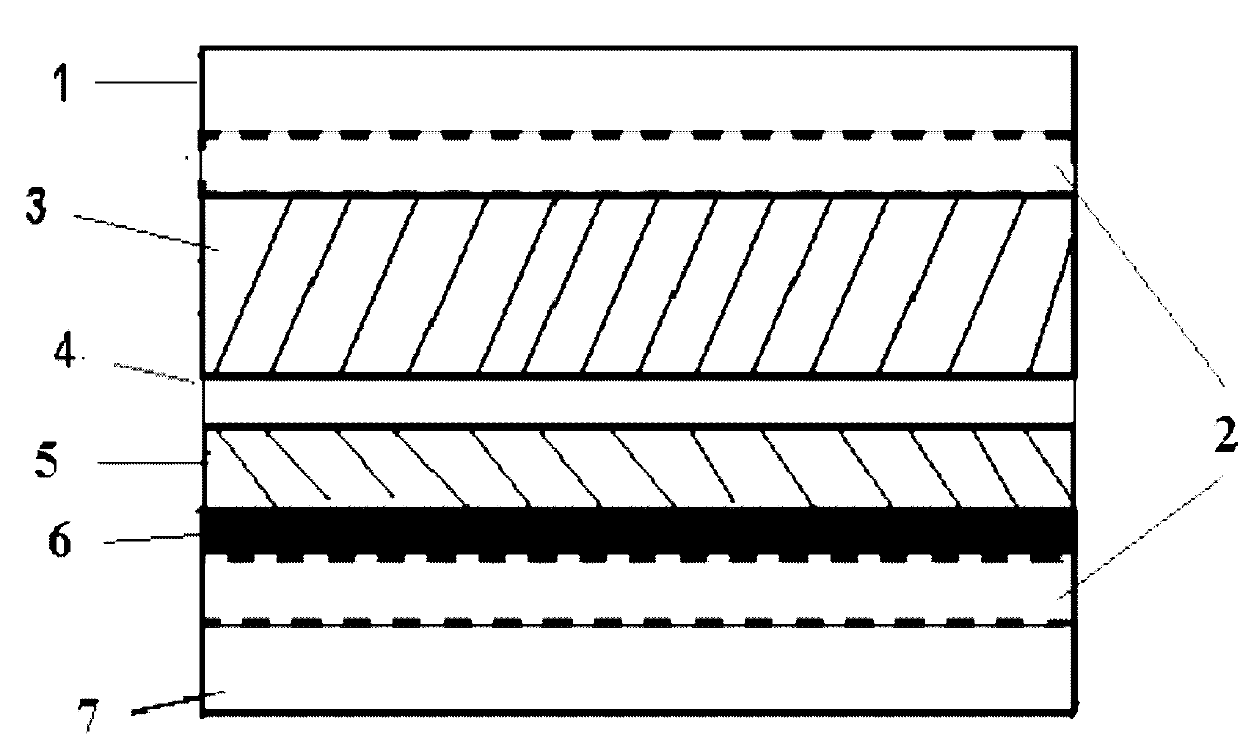

[0020] Embodiment 2 spraying method prepares molybdenum carbide electrode

[0021] The prepared slurry was evenly sprayed on the FTO conductive glass with a spray pen, the spraying distance was controlled at 10 cm, and the spraying pressure was controlled at 1000 Pascal. Under the protection of nitrogen, the electrodes were fired in a tube furnace at 500°C for 30 minutes.

Embodiment 3

[0022] Embodiment 3 printing method prepares molybdenum carbide electrode

[0023] The prepared slurry was printed on the FTO conductive glass with a screen printing machine, and the electrodes were fired in a tube furnace at 500° C. for 30 minutes in a muffle furnace under a nitrogen atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com