Method for preparing strontium ranelate

A strontium ranelate and compound technology, applied in the field of strontium ranelate preparation, can solve the problems of unfavorable post-processing, material stickiness, etc., and achieve the effect of reduced impurity content and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

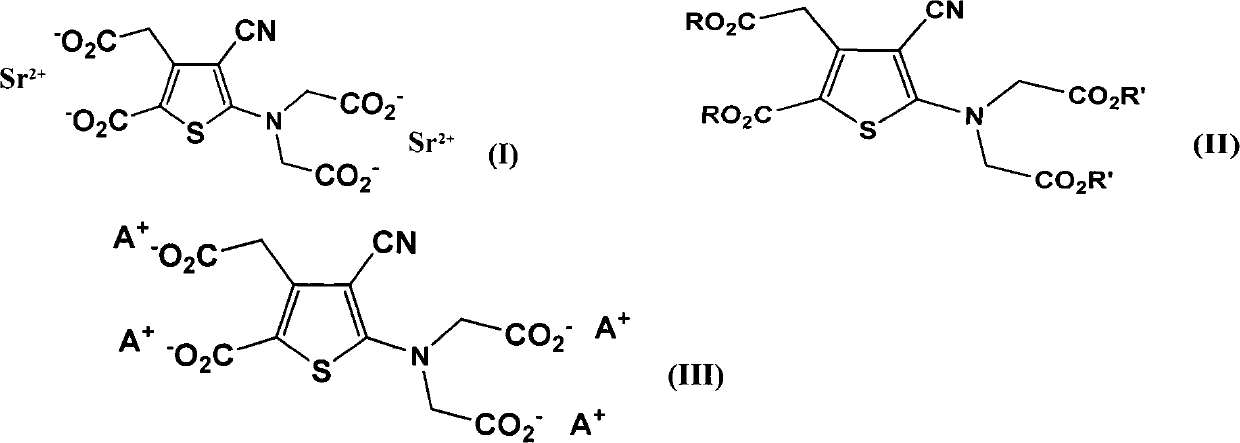

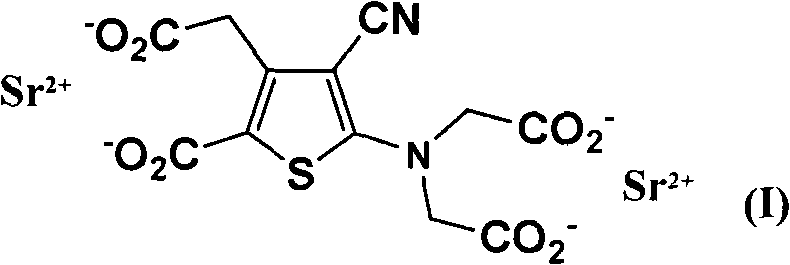

Image

Examples

Embodiment 1

[0054] Add diethyl 3-oxoglutarate (20.2 g, 0.1 mol), malononitrile (6.6 g, 0.1 mol), and 10 mL of ethanol into the reaction flask, cool to 0±5°C, and add triethylamine ( 10.1 g, 0.1 mol) of ethanol mixture in 10 mL, and keep the temperature of the reaction system at 0-10 ° C, about 30 min after the dripping, and react at room temperature at 20-30 ° C for 1 h. Sulfur powder (3.2 g, 0.1 mol) was added, and the temperature was raised to 70-78° C. for reflux reaction for 4 h. Remove from heat and cool to room temperature. Add 30 mL of water, cool to 0±5°C, and precipitate crystals. Filter, and wash the filter cake successively with 10 mL of ethanol and 20 mL of water. After drying the filter cake, 23.1 g of ethyl 5-amino-4-cyano-3-(2-ethoxy-2-oxoethyl)-2-thiophenecarboxylate was obtained (85% yield, 99.0% purity) .

Embodiment 2

[0056]Add 5-amino-4-cyano-3-(2-ethoxyl-2-oxoethyl)-2-thiophenecarboxylic acid ethyl ester (80g, 0.283mol) obtained in Example 1, carbonic acid Potassium (98g, 0.71mol), acetone (600mL) and ethyl bromoacetate (110g, 0.658mol) were stirred rapidly, heated to 50-58°C, and refluxed for 4h. Cool to 20-40°C, filter to remove inorganic salts, and rinse with 40 mL of acetone. The filtrates were combined and concentrated to dryness under reduced pressure. Recrystallize twice with ethanol and dry to get 5-[bis(2-ethoxy-2-oxoethyl)amino]-4-cyano-3-(2-ethoxy-2-oxo Ethyl)-2-thiophenecarboxylic acid ethyl ester 106g (yield 82%, purity greater than 99.5%).

Embodiment 3

[0058] Add Example 2 in the reaction flask to obtain 5-[bis(2-ethoxyl-2-oxoethyl)amino]-4-cyano-3-(2-ethoxyl-2-oxoethyl) )-Ethyl 2-thiophenecarboxylate (20g, 0.044mol), 30mL of tetrahydrofuran, 80mL of aqueous solution of sodium hydroxide (8g, 0.2mol), stirred, controlled the reaction temperature at 10-30°C, and reacted for 5h. A small amount of insoluble solid was removed by filtration, and the filtrate was concentrated under reduced pressure at 35°C to remove the organic solvent. A solution of strontium chloride hexahydrate (25.8 g, 0.092 mol) in 136 mL of water was added with stirring. Crystallize at room temperature for 15h and filter. The filter cake was added to 160 mL of hot water, heated to 95°C for 5 minutes, and filtered while hot to remove strontium hydroxide impurities. Wash with 20mL boiling water. Vacuum drying at 40°C for 12 hours gave 23.1 g of strontium ranelate heptahydrate (yield 82%, purity greater than 99.5%, and individual impurity content less than 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com