Nano-micro structure silibinin drug composite powder and preparation method thereof

A technology of compound powder and silibinin, which is applied in the directions of drug combination, pharmaceutical formulation, powder delivery, etc., can solve the problems of large drug particles, expensive equipment, complicated operation process, etc., and achieves simple composition, easy operation and process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

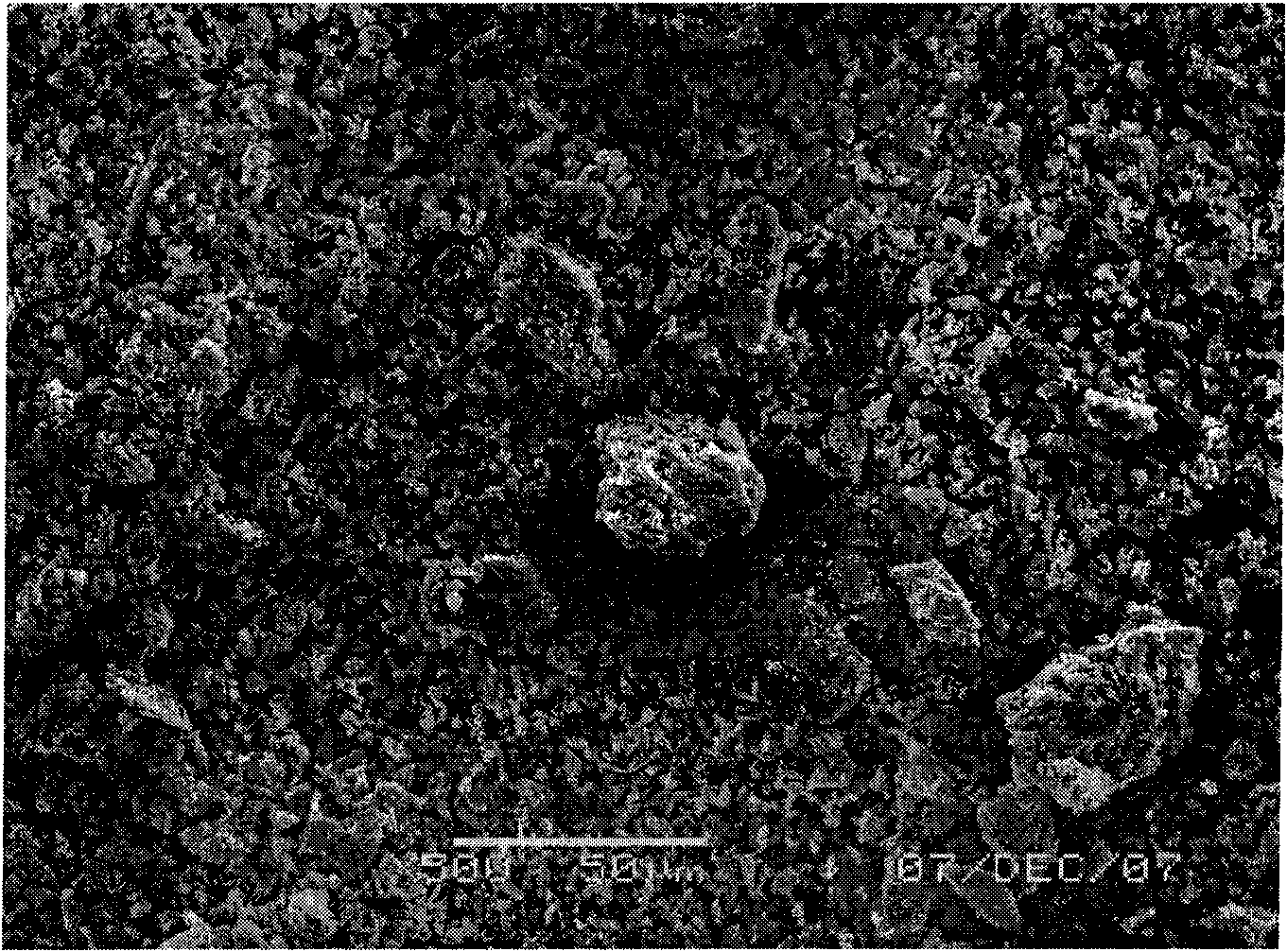

Image

Examples

Embodiment 1

[0038] A: Weigh 1g of silibinin bulk drug and dissolve it in 33.3ml of acetone;

[0039] B: Weigh 18.9g of polyethylene glycol and 0.10g of sodium dodecylbenzenesulfonate and dissolve it in 166.5ml of water, put the beaker containing the aqueous solution in an ice-water bath, and control the temperature of the aqueous solution at about 3°C;

[0040] C: under the stirring condition of 2000rpm, pour the crude drug solution prepared in step A into the aqueous solution of step B to obtain a silibinin nanosuspension;

[0041] D: Control spray drier (SD-Basic, Labplant, UK) inlet temperature is 100 ℃, outlet temperature is 60 ℃, feed rate is 5ml / min, compressed air pressure is 0.6MPa, silybin nano-suspension The solution was spray-dried to obtain nano-microstructure silibinin drug composite powder.

[0042]After the composite powder is dispersed in water, the average particle diameter of the particles is 895.1 nm.

Embodiment 2

[0044] A: Weigh 1g of silibinin bulk drug and dissolve it in 100ml of ethanol;

[0045] B: Weigh 0.5g poloxamer and 0.5g sodium stearate and dissolve in 2000ml water, place the aqueous solution in a constant temperature water bath, and control the temperature of the aqueous solution at about 10°C;

[0046] C: under the stirring condition of 1500rpm, pour the crude drug solution prepared in step A into the aqueous solution of step B to obtain a silibinin nanosuspension;

[0047] D: Control spray drier (SD-Basic, Labplant, UK) inlet temperature is 160 ℃, outlet temperature is 90 ℃, feed rate is 40ml / min, compressed air pressure is 0.8MPa, silybin nano-suspension The solution was spray-dried to obtain nano-microstructure silibinin drug composite powder.

[0048] After the composite powder is dispersed in water, the average particle size of the particles is 774.6nm.

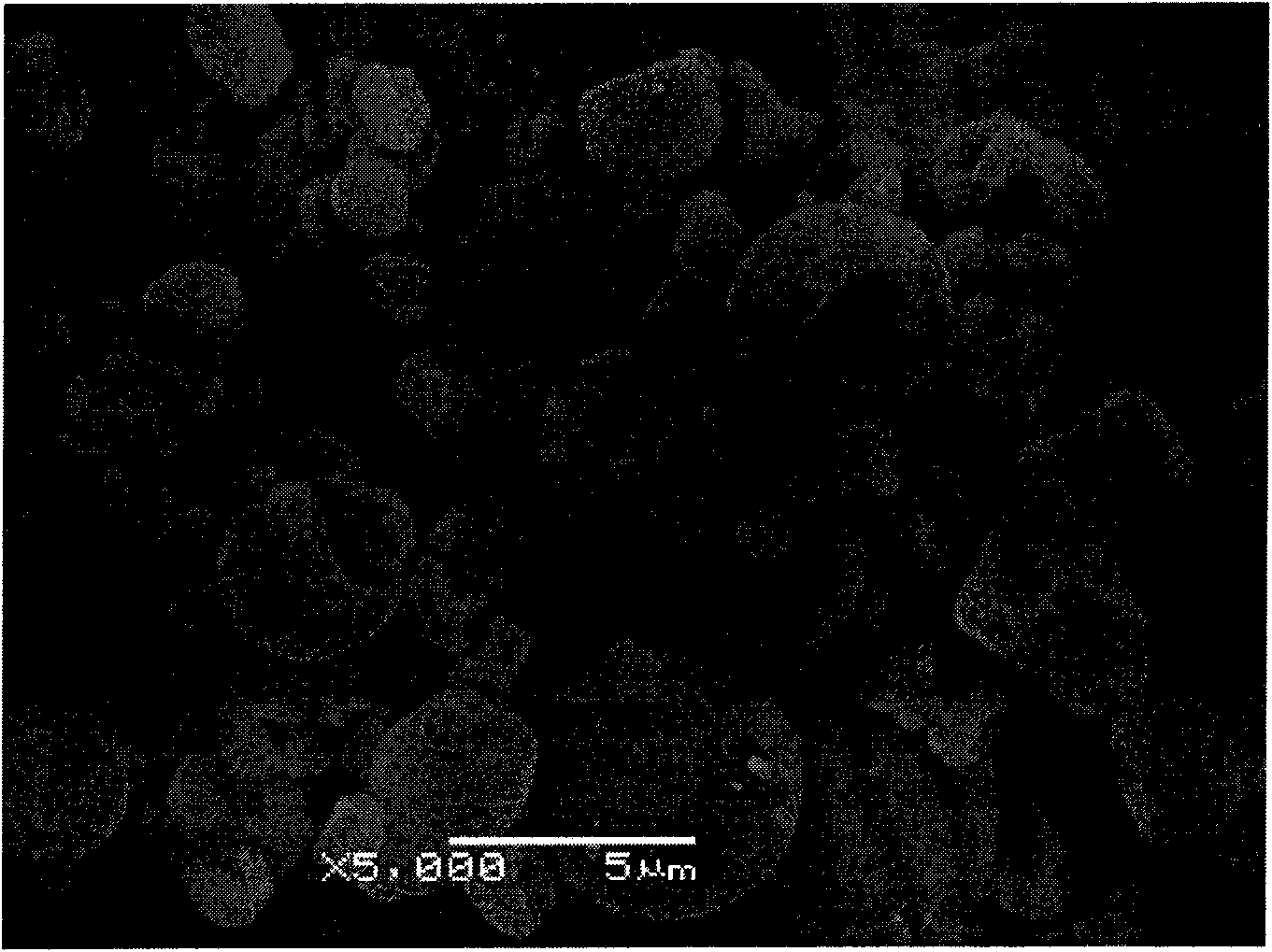

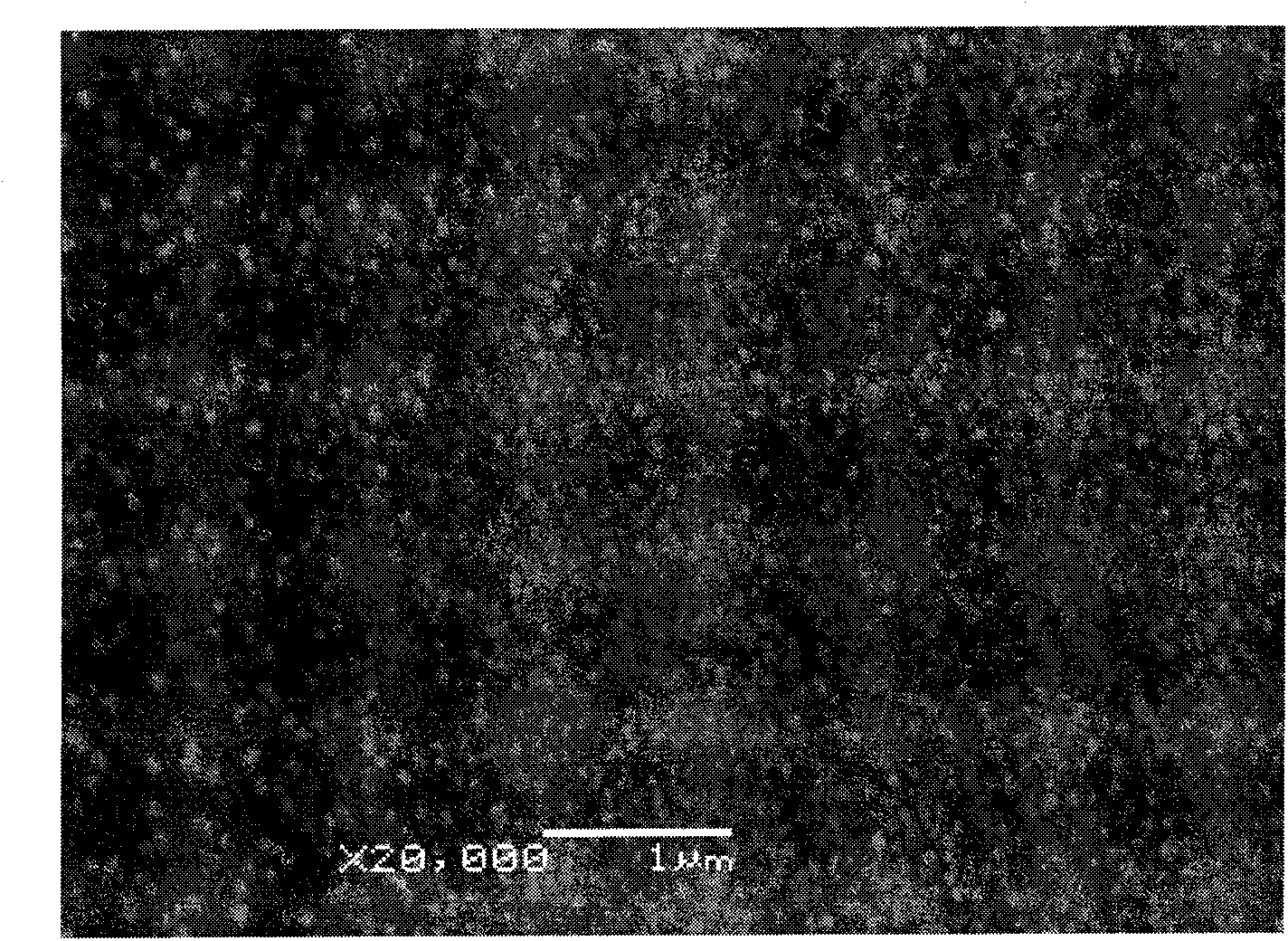

Embodiment 3

[0050] A: Weigh 1g of silybin raw material and dissolve it in 50ml of acetone;

[0051] B: Dissolve 5g of polyvinylpyrrolidone and 0.02g of sodium lauryl sulfate in 500ml of water, place the water solution in a constant temperature water bath, and control the temperature of the solution at about 3°C;

[0052] C: under the stirring condition of 1000rpm, pour the crude drug solution prepared in step A into the aqueous solution of step B to obtain a silibinin nanosuspension;

[0053] D: Control spray drier (SD-Basic, Labplant, UK) inlet temperature is 140 ℃, outlet temperature is 71 ℃, feed rate is 20ml / min, compressed air pressure is 0.6MPa, silybin nano-suspension The solution was spray-dried to obtain nano-microstructure silibinin drug composite powder.

[0054] The composite powder can form a colloid after being dispersed in water, the average particle size of the particles is 71.4nm, and the polydispersity index is 0.103.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com