Substitution and dehydration method for water contained solid materials and device

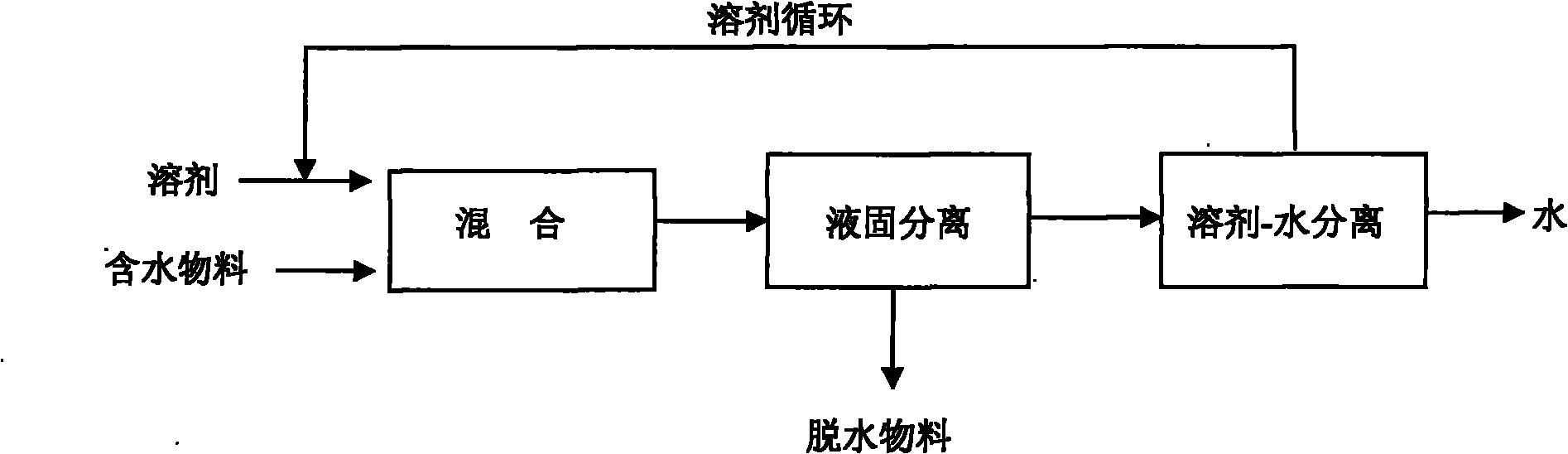

A technology for displacement and dehydration of solid materials, applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting gaseous media with gaseous media. It can solve problems such as high cost and high production capacity, and unsuitable dehydration and drying of bulk solid materials. , to achieve the effect of energy saving, mild operating conditions and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

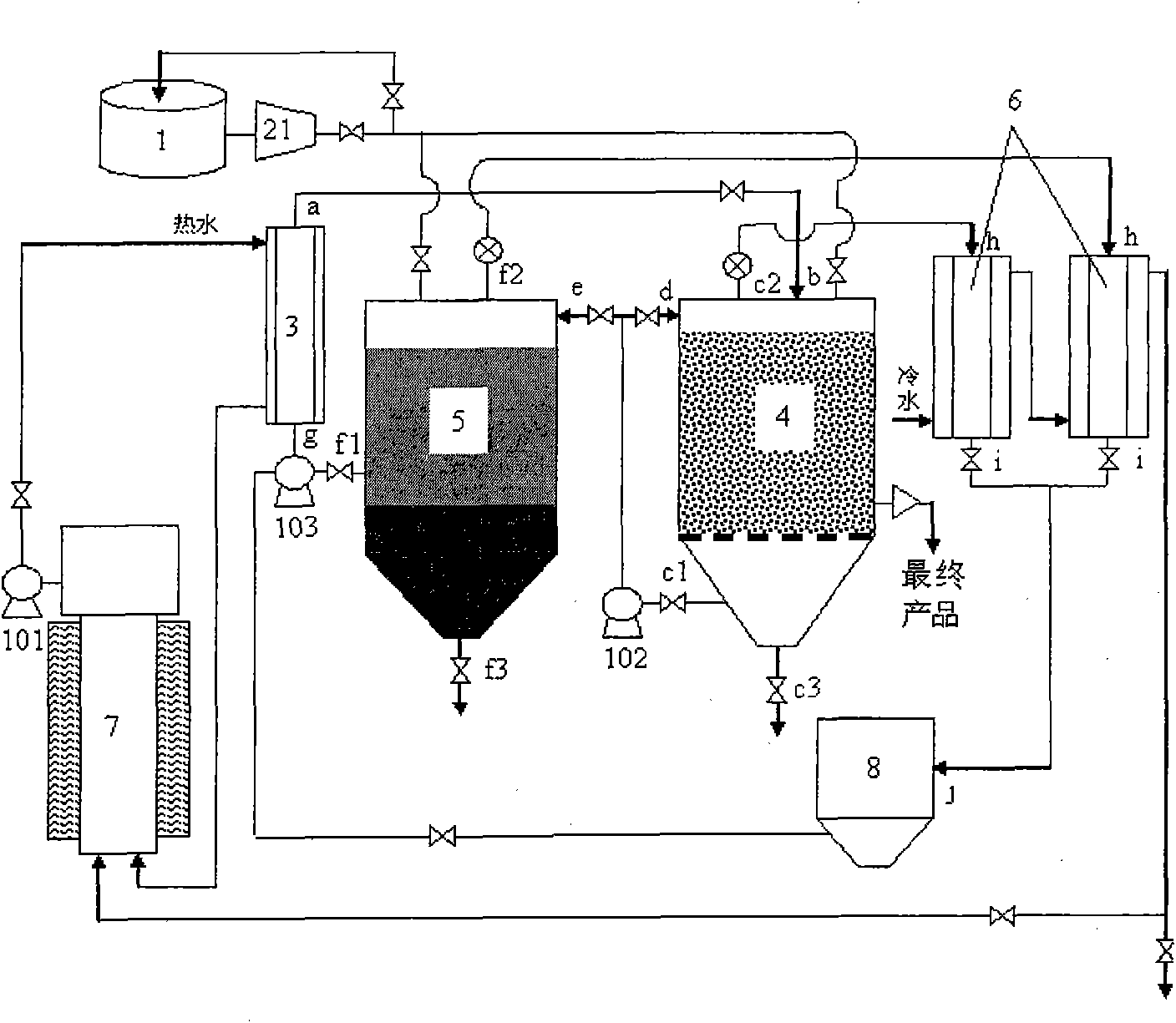

Embodiment 1

[0061] This embodiment is suitable for dehydration of replacement solvents that are liquids at normal temperature and pressure. The schematic diagram of the specific device structure is as follows figure 2 As shown, the device includes: an inert gas cylinder 1, a gas compressor 21, a solvent input device 3, a dehydration device 4, a separation device 5, a condensation recovery device 6, a hot water generator 7, a liquid storage tank 8, and a hot water pump 101 , solvent infusion pumps 102,103. The outlet of the inert gas cylinder 1 is connected with the inlet of the gas compressor 21, and the outlet of the gas compressor 21 is connected with the inlet of the dehydration equipment 4 and the separation equipment 5, so as to provide the required high-pressure gas for the dehydration equipment 4 and the separation equipment 5; the solvent The heating system of the input device 3 is connected with the hot water generator 7, and its solvent inlet g is connected with the liquid solv...

Embodiment 2

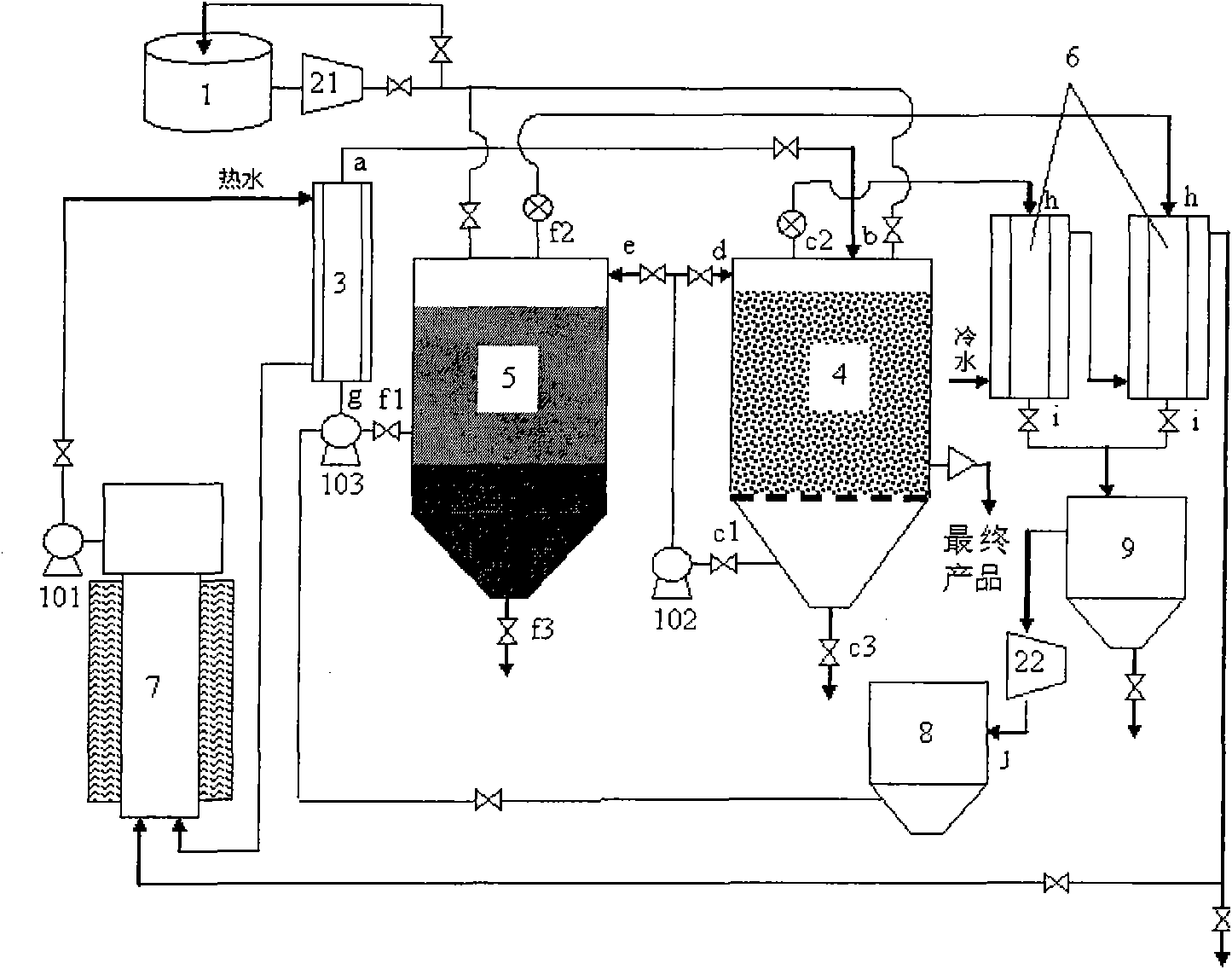

[0065] This embodiment is suitable for the dehydration of the replacement solvent (high-pressure liquid) which is a gas at normal temperature and pressure, and the specific device structure schematic diagram is as follows image 3 As shown, the device includes: inert gas cylinder 1, gas compressor 21, solvent input device 3, dehydration device 4, separation device 5, condensation recovery device 6, hot water generator 7, liquid storage tank 8, gas-liquid separation Tank 9, gas compressors 21, 22, hot water pump 101, solvent infusion pumps 102, 103. The outlet of the inert gas cylinder 1 is connected to the inlet of the gas compressor 21, and the outlet of the gas compressor 21 is connected to the inlet of the dehydration equipment 4 and the separation equipment 5, so as to provide the required high-pressure gas for the dehydration equipment 4 and the separation equipment 5; The heating system of the solvent input device 3 is connected with the hot water generator 7, its solven...

Embodiment 3

[0069] This embodiment is suitable for mixing a liquid organic solvent and a surfactant as a replacement solvent, that is, dehydration of a mixed solvent. The solvent is in a similar state to that of the solvent in Example 1, and the same device can be used. The specific device structure diagram is as follows figure 2 As shown, the device includes: an inert gas cylinder 1, a gas compressor 21, a solvent input device 3, a dehydration device 4, a separation device 5, a condensation recovery device 6, a hot water generator 7, a liquid storage tank 8, and a hot water pump 101 , solvent infusion pumps 102,103. The outlet of the inert gas cylinder 1 is connected with the inlet of the gas compressor 21, and the outlet of the gas compressor 21 is connected with the inlet of the dehydration equipment 4 and the separation equipment 5, so as to provide the required high-pressure gas for the dehydration equipment 4 and the separation equipment 5; the solvent The heating system of the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com