Method for protecting aluminum electrolytic pre-baked anode steel grab

A prebaked anode and aluminum electrolysis technology, which is applied in the field of aluminum electrolysis prebaked anode steel claw protection, can solve problems such as erosion, and achieve the effects of reducing smoke, reducing environmental pollution, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

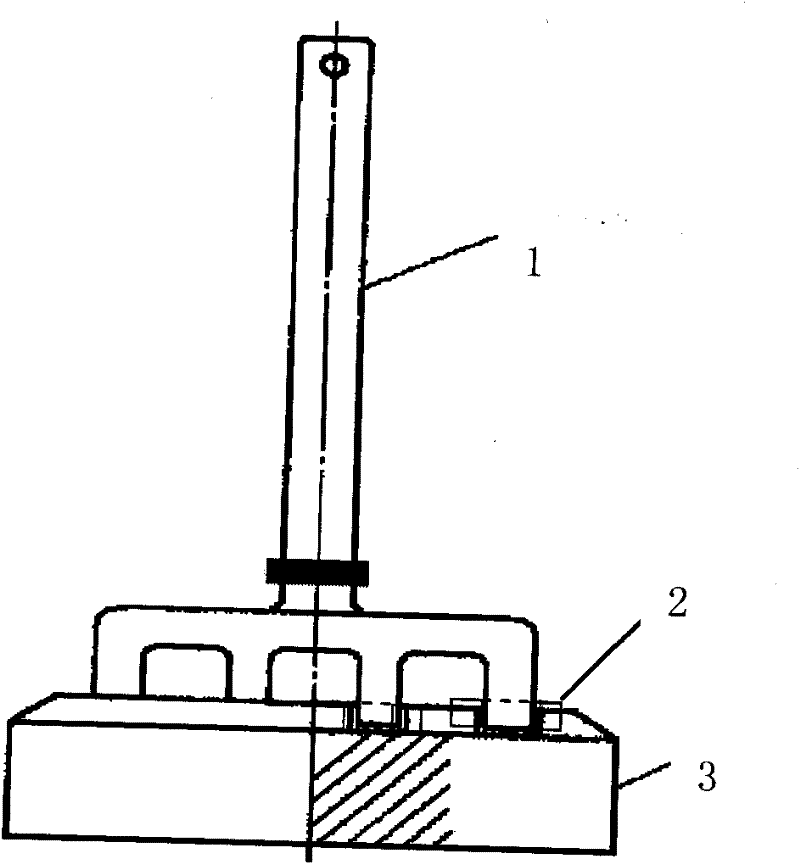

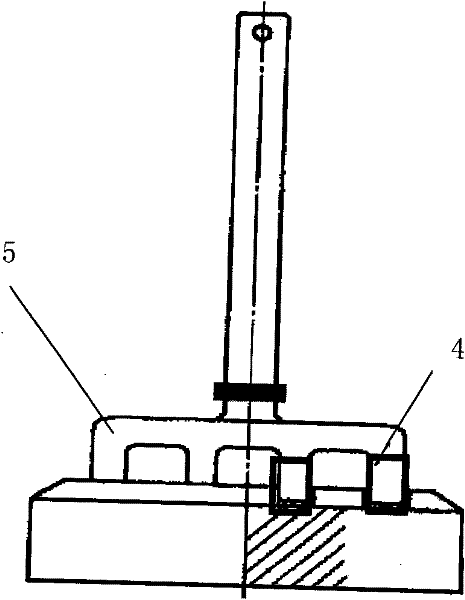

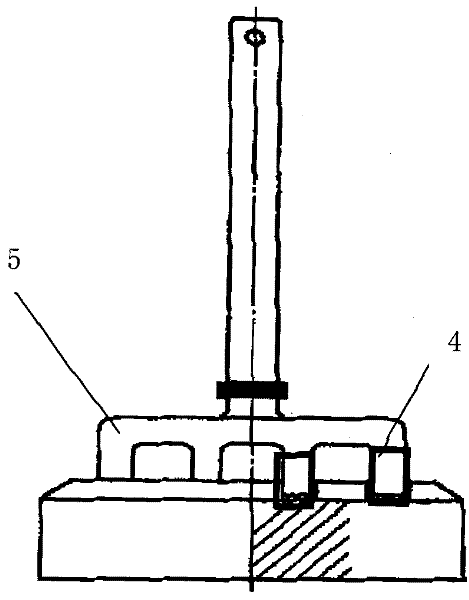

Image

Examples

Embodiment 1

[0020] The raw material formula weight percent of ceramic coating material is: SnO 2 Sol 80%, Sb 2 o 3 2.0%, CuO 2.0%, ZrO 2 3.0%, Fe 2 o 3 3.0%, ZnO 3.0%, Al 2 o 3 3.0%, TiO 2 1.5%, AgO 1.5%, 1% dispersant.

[0021] Preparation:

[0022] 1. With tin tetrachloride (SnCl 4 ·5H 2 O) is the matrix raw material, with water as the solvent, tin tetrachloride is dissolved in water, and is prepared into 0.3mol L -1 SnO 2 Sol;

[0023] 2. Press Sb 2 o 3 2.0%, CuO 2.0%, ZrO 2 3.0%, Fe 2 o 3 3.0%, ZnO 3.0%, Al 2 o 3 3.0%, TiO 2 1.5%, AgO 1.5% formula ratio, adding various metal water-soluble compounds to SnO 2 Sol, using NaOH or ammonia solution, hydrochloric acid as a pH regulator to adjust the pH of the solution between 7 and 9, adding an appropriate amount of epoxy resin and aluminum sol as a binder to make the solution viscous.

[0024] 3. Add 1% ammonium citrate to the solution obtained in step 2 as a dispersant.

[0025] 4. Coat the sol obtained in ...

Embodiment 2

[0027] The raw material formula weight percent of ceramic coating material is: SnO 2 Sol 90%, Sb 2 o 3 1.0%, CuO 1.0%, ZrO 2 1.5%, Fe 2 o 3 1.5%, ZnO 1.5%, Al 2 o 3 1.0%, TiO 2 0.5%, AgO 0.5%, 1.5% dispersant.

[0028] Preparation:

[0029] 1. With tin tetrachloride (SnCl 4 ·5H 2 O) is the matrix raw material, with water as the solvent, tin tetrachloride is dissolved in water, and is prepared into 0.3mol L -1 SnO 2 Sol;

[0030] 2. Press Sb 2 o 3 1.0%, CuO 1.0%, ZrO 2 1.5%, Fe 2 o 3 1.5%, ZnO 1.5%, Al 2 o 3 1.0%, TiO 2 0.5%, AgO 0.5% formula ratio, adding various metal water-soluble compounds to SnO 2 Sol, using NaOH or ammonia solution, hydrochloric acid as a pH regulator to adjust the pH of the solution between 7.0 and 9.0, adding an appropriate amount of epoxy resin and aluminum sol as a binder to make the solution viscous.

[0031] 3. Add 1.5% polyvinyl alcohol to the solution obtained in step 2 as a dispersant.

[0032] 4. Coat the sol obt...

Embodiment 3

[0034] The raw material formula weight percent of ceramic coating material is: SnO 2 Sol 95%, Sb 2 o 3 0.5%, CuO 0.5%, ZrO 2 0.5%, Fe 2 o 3 0.5%, ZnO 0.3%, Al 2 o 3 0.3%, TiO 2 0.2%, AgO 0.2%, 2% dispersant.

[0035] Preparation:

[0036] 1. With tin tetrachloride (SnCl 4 ·5H 2 O) is the matrix raw material, with water as the solvent, tin tetrachloride is dissolved in water, and is prepared into 0.3mol L -1 SnO 2 Sol;

[0037] 2. Press Sb 2 o 3 0.5%, CuO 0.5%, ZrO 2 0.5%, Fe 2 o 3 0.5%, ZnO 0.3%, Al 2 o 3 0.3%, TiO 2 0.2%, AgO 0.2% formula ratio, adding various metal water-soluble compounds to SnO 2 Sol, use NaOH or ammonia solution, hydrochloric acid as pH regulator, adjust the pH value of the solution between 7.0 and 9.0, add an appropriate amount of epoxy resin and aluminum sol as a binder, and make the solution viscous.

[0038] 3. Add 2.0% polyacrylic acid amine as a dispersant to the solution obtained in step 2.

[0039] 4. Coat the sol obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com