Preparation method of Barium Titanate nano-powder

A nano-powder, barium titanate technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of large product particle size, high production pressure of hydrothermal method, complex process, etc., and achieve uniform particle size distribution. , the effect of high relative dielectric constant and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

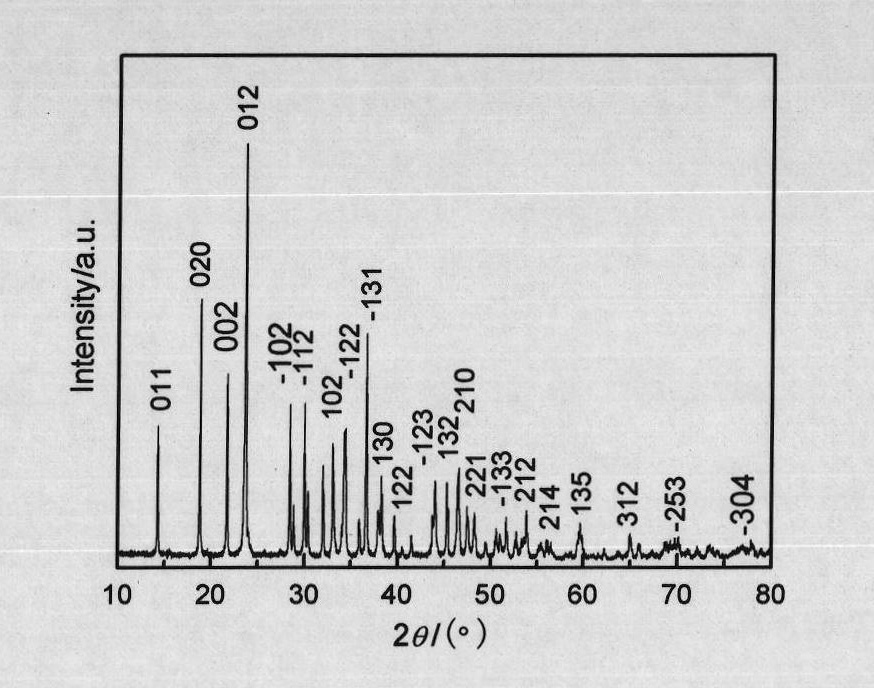

[0019] (1) Weigh 1.22g BaCl 2 2H 2 O was added to 20 mL of 3% H 2 o 2 In solution, BaCl 2 2H 2 O and H 2 o 2 The ratio of the amount of the substances is 1:3.9, and constantly stirred. Then, add an appropriate amount of ammonia water to adjust the pH of the solution to 8.5, and let it stand for 30 minutes to obtain a yellow precipitate. Filtrate, wash the precipitate alternately with dilute ammonia water and absolute ethanol, and dry it in a vacuum oven at room temperature to obtain light yellow precursor powder BaO 2 ·H 2 o 2 . to BaO 2 ·H 2 o 2 Carry out X-ray diffraction (XRD) analysis to know that the prepared BaO 2 ·H 2 o 2 It is a monoclinic crystal system without impurity peaks, indicating that BaO 2 ·H 2 o 2 High purity, such as figure 1 shown.

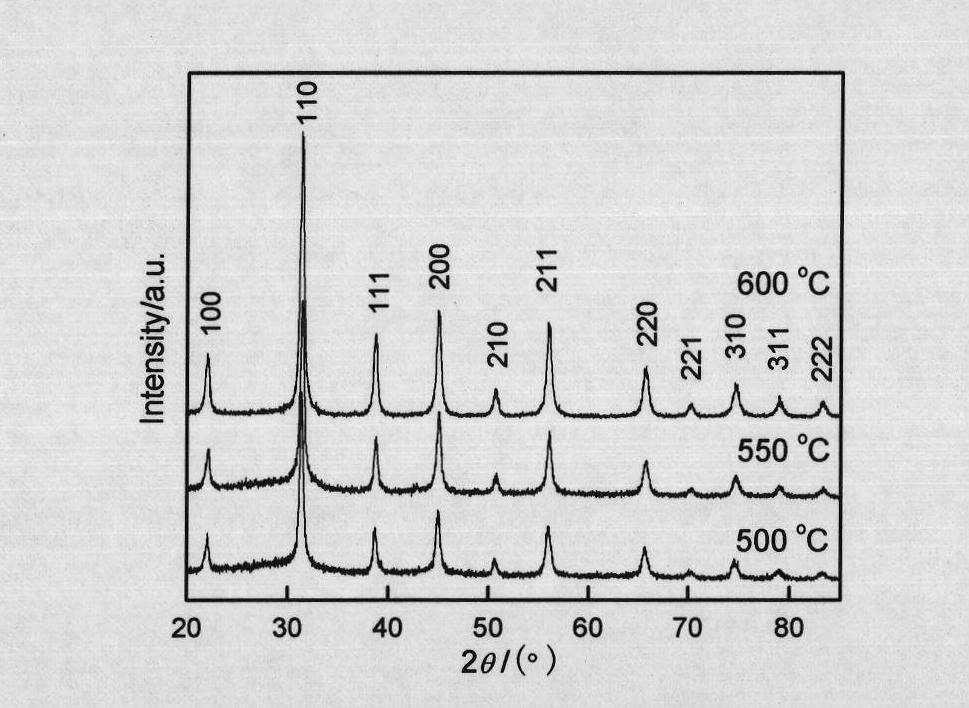

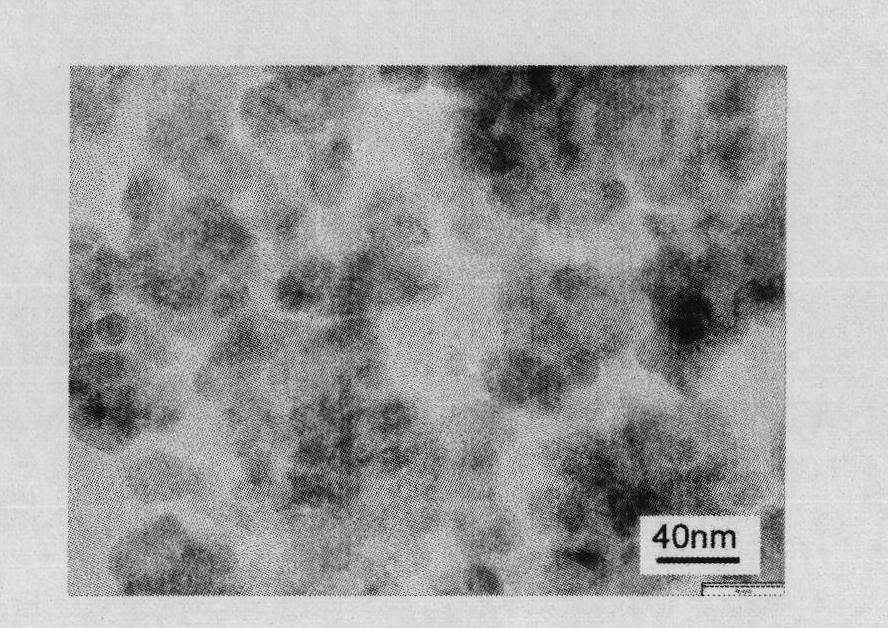

[0020] (2) Weigh 2.03g BaO 2 ·H 2 o 2 and 0.59g H2 TiO 3 Put it in a mortar, mix and grind evenly, then add 1.69g KOH, 10.00g KNO 3 and 10 mL absolute ethanol (BaO 2 ·H 2 o 2 with H 2 TiO 3 The r...

Embodiment 2

[0023] (1) Weigh 2.42g Ba(NO 3 ) 3 ·5H 2 O was added to 8 mL of 9% H 2 o 2 In solution, Ba(NO 3 ) 3 ·5H 2 O and H 2 o 2 The ratio of the amount of the substances is 1:4.7, and keep stirring. Then, add an appropriate amount of ammonia water to adjust the pH of the solution to 10, and let it stand for 20 minutes to obtain a yellow precipitate. Filtrate, wash the precipitate alternately with dilute ammonia water and absolute ethanol, and dry it in a vacuum oven at room temperature to obtain light yellow precursor powder BaO 2 ·H 2 o 2 . to BaO 2 ·H 2 o 2 Carry out X-ray diffraction (XRD) analysis to know that the prepared BaO 2 ·H 2 o 2 It is a monoclinic crystal system without impurity peaks, indicating that BaO 2 ·H 2 o 2 High purity.

[0024] (2) Weigh 2.03g BaO 2 ·H 2 o 2 and 0.39g H 2 TiO 3 Put it in a mortar, mix and grind evenly, then add 1.12g KOH, 8.29g KNO 3 and 8 mL absolute ethanol, BaO 2 ·H 2 o 2 with H 2 TiO 3 The ratio of the amount...

Embodiment 3

[0027] (1) Weigh 1.37g Ba(CH 3 COO) 3 ·H 2 O was added to 10 mL of 5% H 2 o 2 In solution, Ba(CH 3 COO) 3 ·H 2 O and H 2 o 2 The ratio of the amount of the substances is 1: 3.2, and constantly stirred. Then, add an appropriate amount of ammonia water to adjust the pH of the solution to 9, and let it stand for 25 minutes to obtain a yellow precipitate. Filtrate, wash the precipitate alternately with dilute ammonia water and absolute ethanol, and dry it in a vacuum oven at room temperature to obtain light yellow precursor powder BaO 2 ·H 2 o 2 . to BaO 2 ·H 2 o 2 Carry out X-ray diffraction (XRD) analysis to know that the prepared BaO 2 ·H 2 o 2 It is a monoclinic crystal system without impurity peaks, indicating that BaO 2 ·H 2 o 2 High purity.

[0028] (2) Weigh 3.05g BaO 2 ·H 2 o 2 and 0.73g H 2 TiO 3 Put it in a mortar, mix and grind evenly, then add 2.19g KOH, 13.6g KNO 3 and 12mL absolute ethanol (BaO 2 ·H 2 o 2 with H 2 TiO 3 The ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com