Treated refractory material and methods of making

A refractory material and refractory technology, applied in nanotechnology, ceramic products, applications, etc. for materials and surface science, can solve problems such as refractory decline and achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

[0049]Sintered high chromium oxide (90% by weight) bricks were infiltrated several times with a solution of chromium(III) nitrate, followed by heat treatment at 600° C. in air for 2 hours to decompose the nitrates into chromium oxides. After full penetration, the weight of the protective material constitutes about 10% by weight of the refractory brick. The infiltrated bricks were then annealed in nitrogen at 1600° C. for 20 hours to pre-react the chromia prior to slag infiltration. The porosity of the untreated refractory prior to slag infiltration was about 18-20% by volume. After infiltration and heat treatment, the porosity is about 12-14% by volume.

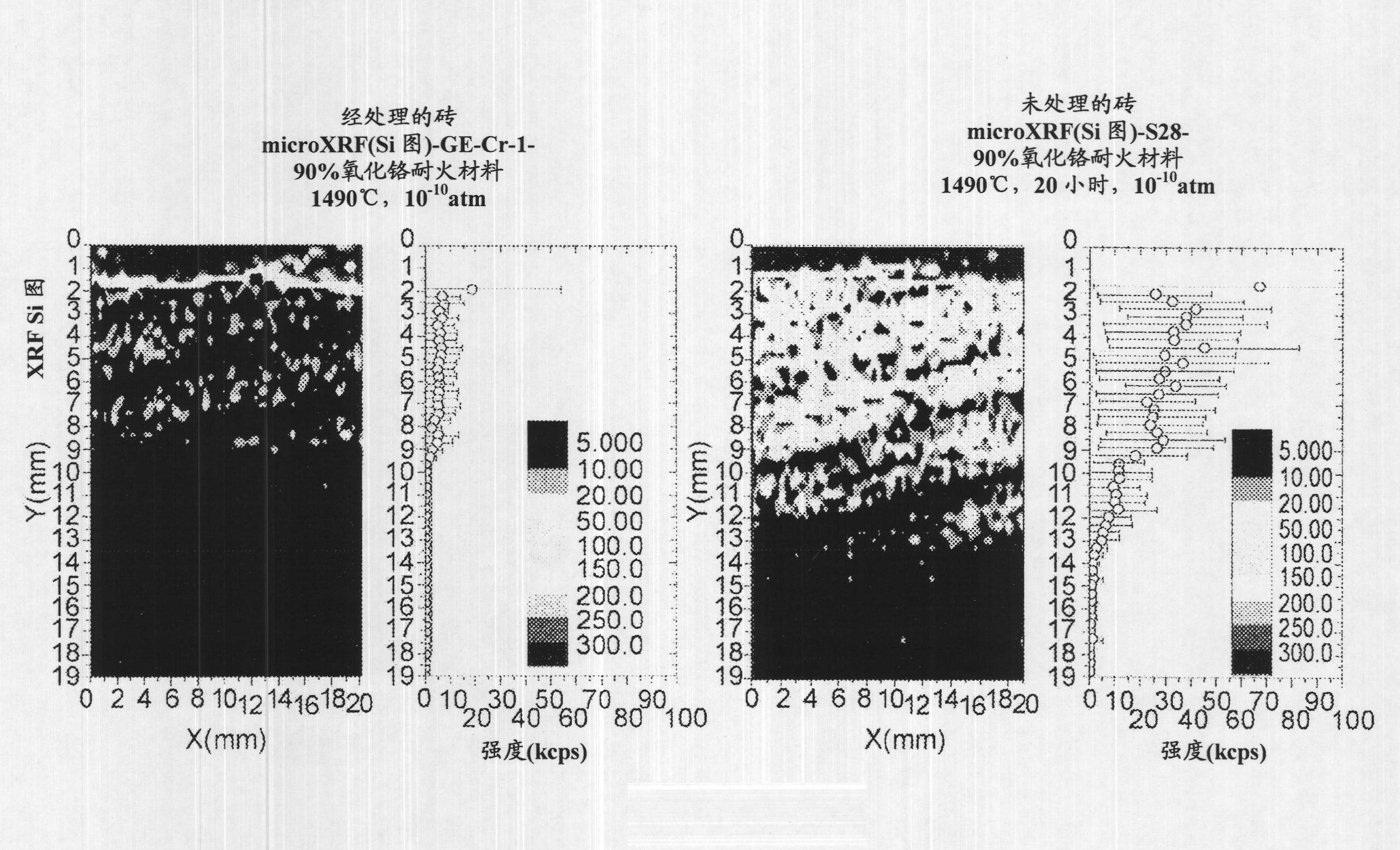

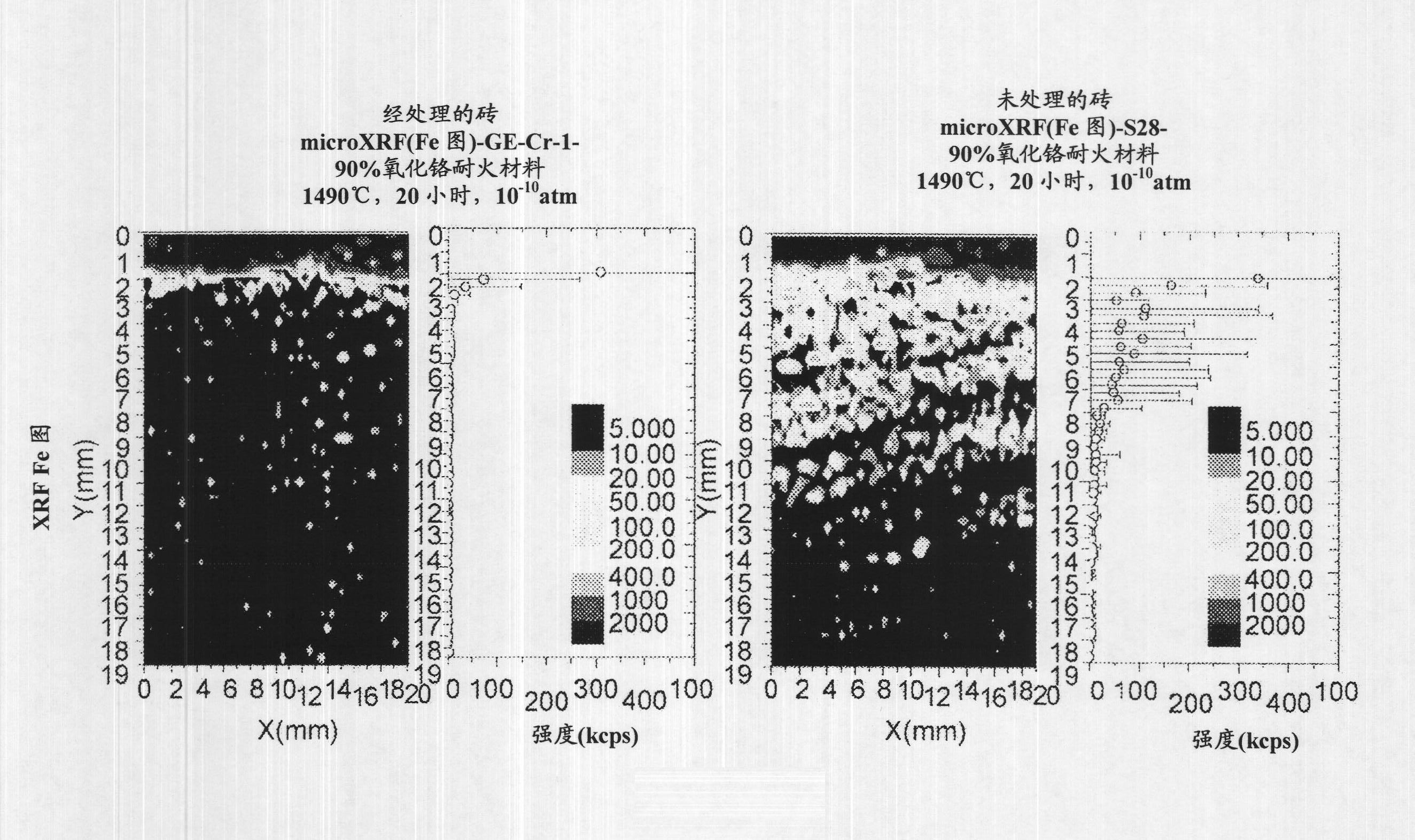

[0050] Slag infiltration tests with slag-filled cups for isothermal annealing were performed on bricks infiltrated with chromia and untreated bricks. The slag composition contained 59.0% silica, 10.7% alumina, 8.3% calcium oxide, 21.6% iron oxide and 0.3% potassium oxide. The test parameters are 1490°C, 20 hours, 10^-10atm...

Embodiment 2

[0052] Example 1 was repeated except that chromium(III) acetate (Cr3(OH)3(CH3COO)2) was used as the precursor of the chromium oxide protective material. Slag infiltration tests with slag-filled cups for isothermal annealing were performed on bricks infiltrated with chromia and untreated bricks. The test parameters are 1500°C, 20 hours, 10^-10atm oxygen partial pressure provided by a mixture of wet and dry N2 / 3%H2 gas.

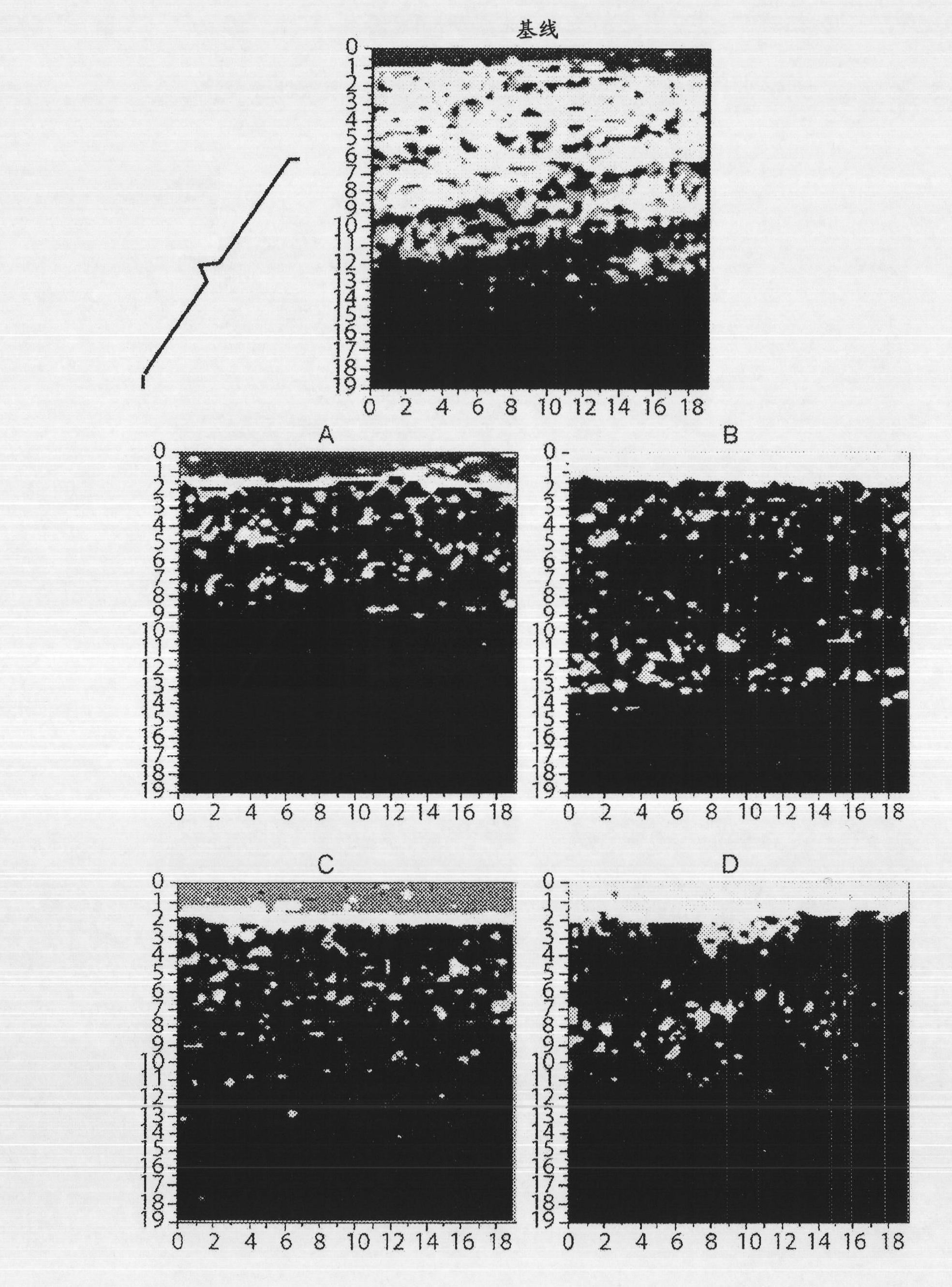

[0053] Subsequent analysis of the slag penetration by XRF patterns of the Si distribution in the brick cross-section showed that the slag penetration was much smaller in the treated bricks than in the untreated bricks. image 3 A shows XRF patterns of slag-infiltrated Si for untreated bricks and bricks treated with chromia. Example 3

Embodiment 3

[0054] Example 1 was repeated except that aluminum nitrate was used as the precursor for the alumina protective material. Slag infiltration tests with slag-filled cups for isothermal annealing were performed on bricks infiltrated with alumina and untreated bricks. The test parameters are 1500°C, 20 hours, 10^-10atm oxygen partial pressure provided by a mixture of wet and dry N2 / 3%H2 gas.

[0055] Subsequent analysis of the slag penetration by XRF patterns of Si distribution in the brick cross-section revealed that the slag penetration in the treated bricks was much smaller than in the untreated baseline bricks. image 3 B shows XRF patterns of slag-infiltrated Si for untreated bricks and bricks treated with alumina. Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com