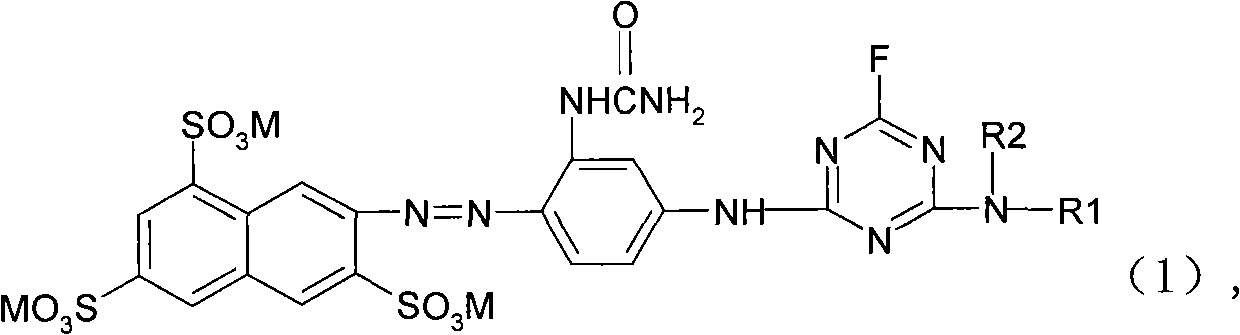

Yellow fluorine-containing triazine reactive dye and preparation method and application thereof

A technology of reactive dyes and production methods, which is applied in the field of yellow fluorine-containing triazine reactive dyes and its preparation, can solve the problems of poor compatibility, high chroma of dyeing residual liquid, and insufficient color fixation rate, and achieve good environmental benefits , high color fixation rate and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 prepares dyestuff, operates according to the following steps:

[0041] a, diazotization reaction

[0042] Put bottom water and bottom ice in the diazonium pot, drop in 383 parts of the compound of formula (2) and 91 parts of hydrochloric acid, and beat for 35 minutes. After making 70 parts of sodium nitrite into a 30% aqueous solution, add it into the solution of the compound of formula (2), maintain T=2.5°C, and use sulfamic acid to eliminate excess sodium nitrite after reacting for 2 hours. When the starch potassium iodide test paper is colorless, the Congo red test paper is blue, and the end point is reached, the diazo solution is obtained.

[0043] b. Coupling reaction

[0044] Put 151 parts of the dry powder of the compound of formula (3) into the diazonium solution prepared in step a, adjust pH=6.3 with 20% soda water after reacting for 35 minutes, maintain T=10°C, and reach the end point after reacting for 4.5 hours to obtain the coupling liquid. ...

Embodiment 2

[0052] Embodiment 2 prepares dyestuff, operates according to the following steps:

[0053] a, diazotization reaction

[0054] Put bottom water and bottom ice in the diazo pot, drop in 479 parts of the compound of formula (2) and 114 parts of hydrochloric acid, and beat for 40 minutes. After making 88 parts of sodium nitrite into a 30% aqueous solution, add it into the solution of the compound of formula (2), maintain T=1°C, and use sulfamic acid to eliminate excess sodium nitrite after reacting for 2 hours. When the starch potassium iodide test paper is colorless, the Congo red test paper is blue, and the end point is reached, the diazo solution is obtained.

[0055] b. Coupling reaction

[0056] Put 189 parts of dry powder of the compound of formula (3) into the diazonium solution prepared in step a, react for 40 minutes, adjust pH=6.5 with 20% soda water, keep T=8°C for 5 hours, and then reach the end point to obtain the coupling solution .

[0057] c, a condensation rea...

Embodiment 3

[0064] Embodiment 3 prepares dyestuff, operates according to the following steps:

[0065] a, diazotization reaction

[0066] Put bottom water and bottom ice in the diazonium pot, drop in 575 parts of the compound of formula (2) and 137 parts of hydrochloric acid, and beat for 35 minutes. After making 106 parts of sodium nitrite into a 30% aqueous solution, add it into the solution of the compound of formula (2), maintain T=5°C, and use sulfamic acid to eliminate excess sodium nitrite after reacting for 2 hours. When the starch potassium iodide test paper is colorless, the Congo red test paper is blue, and the end point is reached, the diazo solution is obtained.

[0067] b. Coupling reaction

[0068] Put 227 parts of the dry powder of the compound of formula (3) into the diazo solution prepared in step a, react for 30 minutes, adjust the pH to 6.3 with 20% soda water, keep T=15°C for 4.5 hours, and then reach the end point to obtain the coupling solution .

[0069] c, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com