Fluorine-containing network structure ion exchange membrane based on fluoroethyl vinyl ether polyalcohol and preparation method thereof

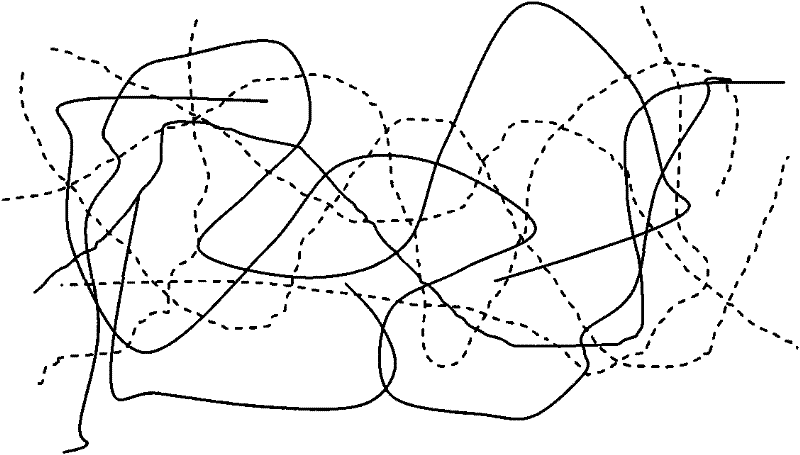

A technology of fluoroethyl vinyl ether and ion-exchange membrane, applied in the field of ion-exchange membranes, can solve the problems of difficulty in controlling the composite process of membrane materials, difficulty in large-scale batch production, and environmental pollution of sulfonating agents, and achieve the reduction of membrane protons. Excellent exchange resistance, strong electrochemical corrosion resistance, and simple film production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

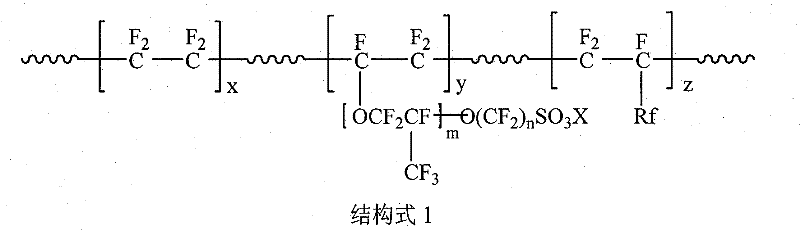

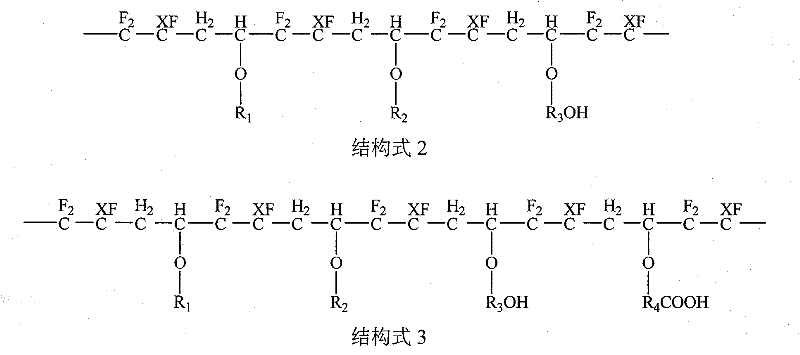

[0044] With 120g dry sulfonic acid resin (number average molecular weight 80,000, exchange capacity 1.27mmol / g, H + type) was dissolved in 880g N,N-dimethylformamide (DMF) under anhydrous conditions to obtain a sulfonic acid solution (casting solution), and anhydrous toluene-2,4-diisocyanate 4.5g, fluoroethyl Vinyl ether polyol (FEVE, such as structural formula 3, X is Cl, R 1 is ethyl, R 2 is propyl, R 3 for CH 2 CH 2 CH 2 , R 4 for CH 2 ) 4.0g (the ratio of the number of hydroxyl groups -OH to the number of cyanate groups -NCO is 1:1), after fully dissolving and stirring evenly, drool on a smooth and horizontal glass surface under anhydrous conditions, at 55°C After evaporating the solvent for 1 hour, the temperature was raised to 160° C. to form a film, which was peeled off from the glass to obtain an ion-exchange membrane, and treated with 5% sulfuric acid to obtain an ion-exchange membrane with an interpenetrating network structure with a film thickness of 50 micro...

Embodiment 2

[0046] With 45g dry sulfonic acid resin (number average molecular weight 160,000, exchange capacity 2.56mmol / g, Na + type) was dissolved in 880g N-methyl-2-pyrrolidone (NMP) under anhydrous conditions to obtain a sulfonic acid solution (casting solution), and anhydrous 4,4'-diphenylmethane diisocyanate (MDI) was added Anhydrous fluoroethyl vinyl ether polyol (FEVE, such as structural formula 3, X is Cl, R 1 is ethyl, R 2 is propyl, R 3 for CH 2 CH 2 CH 2 CH 2 , R 4 for CH 2 ) a total of 44g (the ratio of the number of hydroxyl groups-OH to the number of cyanate groups-NCO is 1:0.8), fully dissolved, stirred evenly, and salivated on the surface of a smooth and horizontal Hastelloy plate under anhydrous conditions. Raise the temperature to 150°C to evaporate the solvent for 1 hour to form a film, peel off the glass to obtain an ion-exchange membrane, fluoride with fluorine gas, and then treat with 5% hydrochloric acid to obtain an ion-exchange membrane with an interpenet...

Embodiment 3

[0048] With 420g dry sulfonic acid resin (number average molecular weight 240,000, exchange capacity 1.05mmol / g, Na + type) was dissolved in 880g N,N-dimethylacetamide (DMAc) under anhydrous conditions to obtain a sulfonic acid solution (casting solution), and anhydrous triphenylmethane triisocyanate (TTI), anhydrous fluorine Ethyl vinyl ether polyol (FEVE, such as structural formula 3, X is CF 3 , R 1 is ethyl, R 2 Cyclohexyl, R 3 for CH 2 CH 2 CH 2 , R 4 for CH 2 ) a total of 210g (the ratio of the number of hydroxyl groups - OH to the number of cyanate groups - NCO is 1: 1.5), fully dissolved, stirred evenly, and salivated on a smooth and horizontal glass surface under anhydrous conditions, at 100 ° C Evaporate the solvent for 2 hours to form a film, peel off the glass to obtain an ion exchange membrane, and treat it with 12% hydrochloric acid to obtain an ion exchange membrane with an interpenetrating network structure with a film thickness of 150 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com