Method for preparing colloid crystal template of orthorhombic La2CuO4 with three-dimensional macro-porous structure

A pore structure and template method technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of inability to prepare, difficult to prepare porous perovskite-like oxides, etc., and achieve good catalytic activity, pore size, etc. The effect of controllable size and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

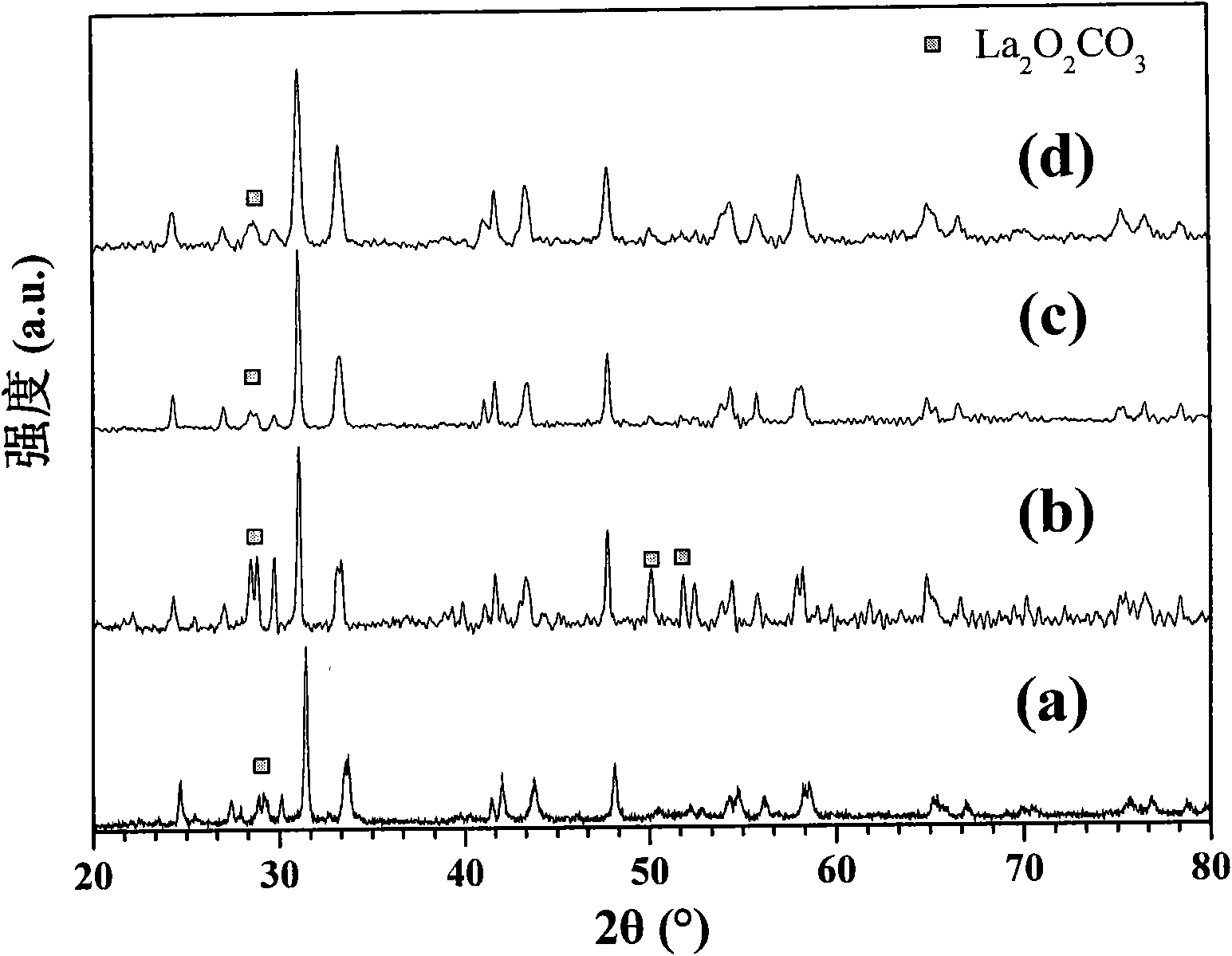

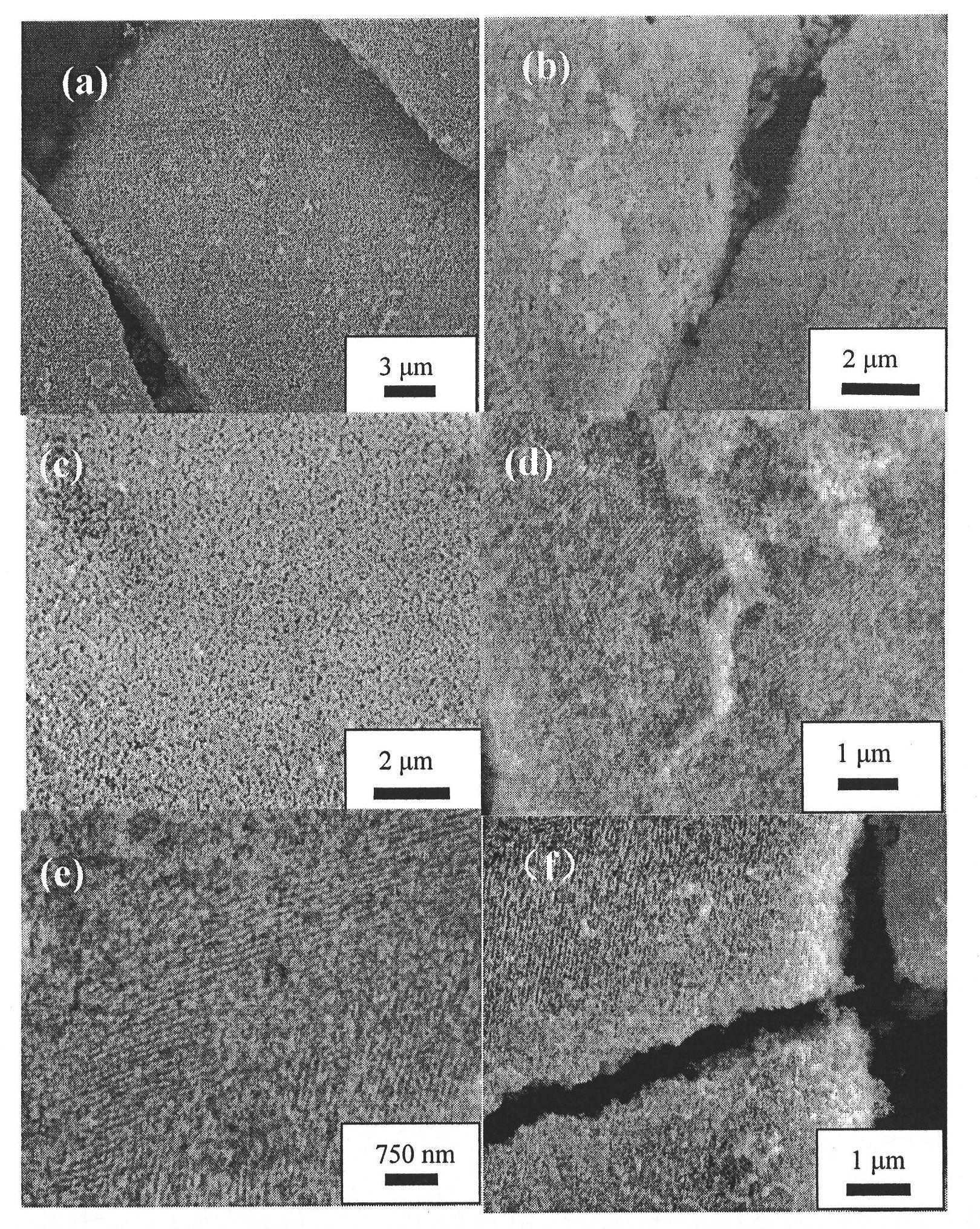

[0018] Embodiment 1: take by weighing 2.1365g La(NO 3 ) 3 ·6H 2 O and 0.5960g Cu(NO 3 ) 2 ·3H 2 O, put in a 100mL beaker, add 5mL of ethylene glycol, stir magnetically for 1 hour, then add 20mL of ethylene glycol solution with a methanol volume percentage of 40%. The above mixed solution was poured into a 100 mL beaker containing 1.0095 g of polymethyl methacrylate (PMMA). In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. The sample obtained after the mixture was soaked in PMMA for 5 h and filtered with suction was dried at room temperature for 12 h, and then the sample was loaded into a magnetic boat and raised from room temperature to 800 °C at a rate of 1 °C / min in a muffle furnace. Keeping it for 5h, the orthorhombic phase La with a three-dimensional wormhole structure is obtained 2 CuO 4 Particles (which contain a small amount of La 2 o 2 CO 3 heterogeneous phase), the pore size is between ...

Embodiment 2

[0019] Embodiment 2: take by weighing 2.1380g La(NO 3 ) 3 ·6H 2 O and 0.5980g Cu(NO 3 ) 2 ·3H 2 O and 1.9960 g of citric acid were placed in a 100 mL beaker, 5 mL of ethylene glycol was added, and after magnetic stirring for 1 h, 20 mL of ethylene glycol solution with a methanol volume percentage of 40% was added. The above mixture was poured into a 100mL beaker containing 1.0095g PMMA. In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. The sample obtained after the mixture was impregnated with PMMA for about 5 hours and suction filtered was dried at room temperature for 12 hours. Keeping at temperature for 5h, the orthorhombic phase La with a three-dimensional wormhole structure is obtained 2 CuO 4 Particles (which contain a small amount of La 2 o 2 CO 3 heterogeneous phase), the pore size is between 67-93nm.

Embodiment 3

[0020] Embodiment 3: take by weighing 2.1364g La(NO 3 ) 3 ·6H 2 O and 0.5961g Cu(NO 3 ) 2 ·3H 2 O In a 100mL beaker, add 5mL of ethylene glycol, stir magnetically for 1h, then add 20mL of ethylene glycol solution with a methanol volume percentage of 40%, and pour the above mixed solution into a 100mL beaker containing 1.0126g of PMMA. In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. After the mixed solution was soaked in PMMA for about 5 hours and filtered with suction, the sample obtained was dried at room temperature for 12 hours, and then the sample was loaded into a magnetic boat and placed in a tube furnace. 2 Under the atmosphere, it was raised from room temperature to 700°C at a rate of 1°C / min and kept at this temperature for 4 hours. After the temperature dropped to 50°C, it was switched to an air atmosphere, and then raised to 300°C at a rate of 1°C / min. Keep at this temperature for 3h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com